Product Details

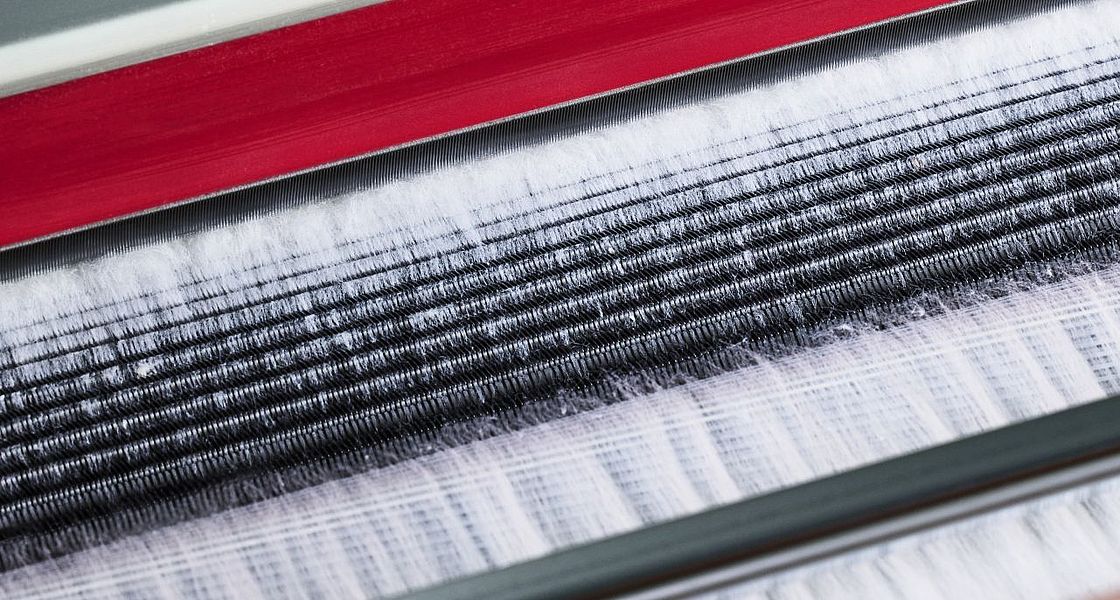

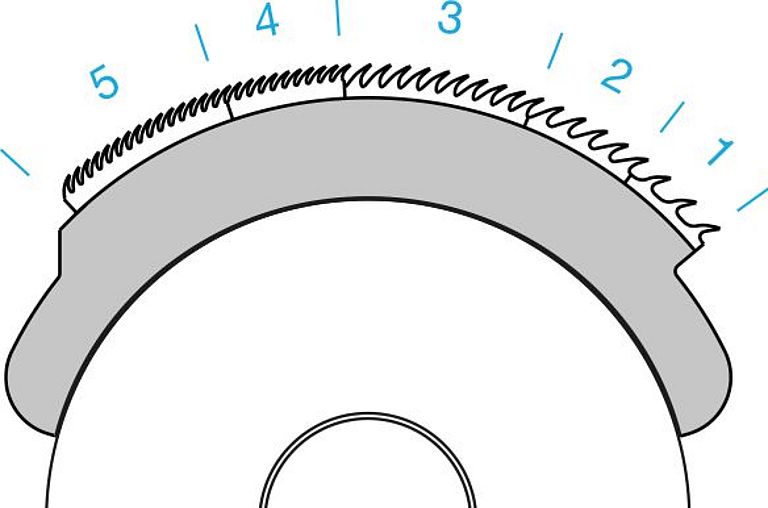

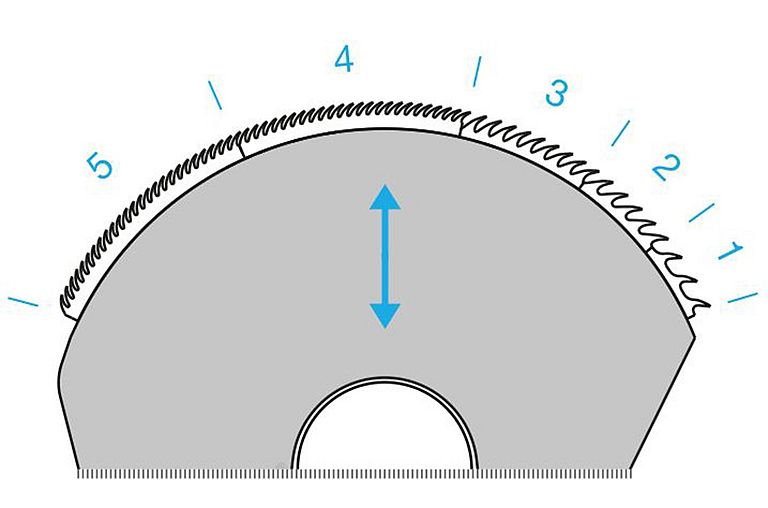

Perfect parallel alignment between the circular comb and the nipper results in maximized yield. That is the secret of the Graf circular combs. They are designed for high-performance combers that perfectly process fibers in any application.

The large combing surface provides a reasonably long processing time for each fiber, especially for comber units running at high nip rates.