Product Details

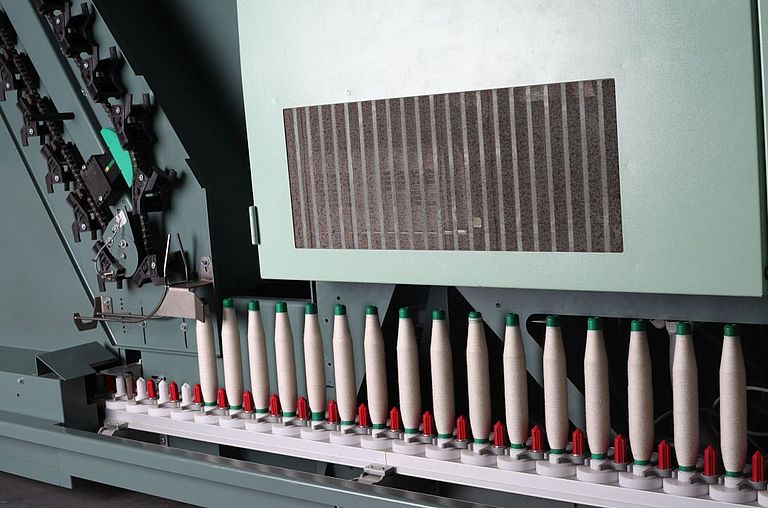

A frequent and repeated maintenance of the doffer as well as checking and resetting the system has a significant impact on the machine efficiency, especially in the mid and long-term. If the doffing cycle is delayed, for instance due to an elongated servo disc belt the productivity of the spinning machine will drop and impact costs.