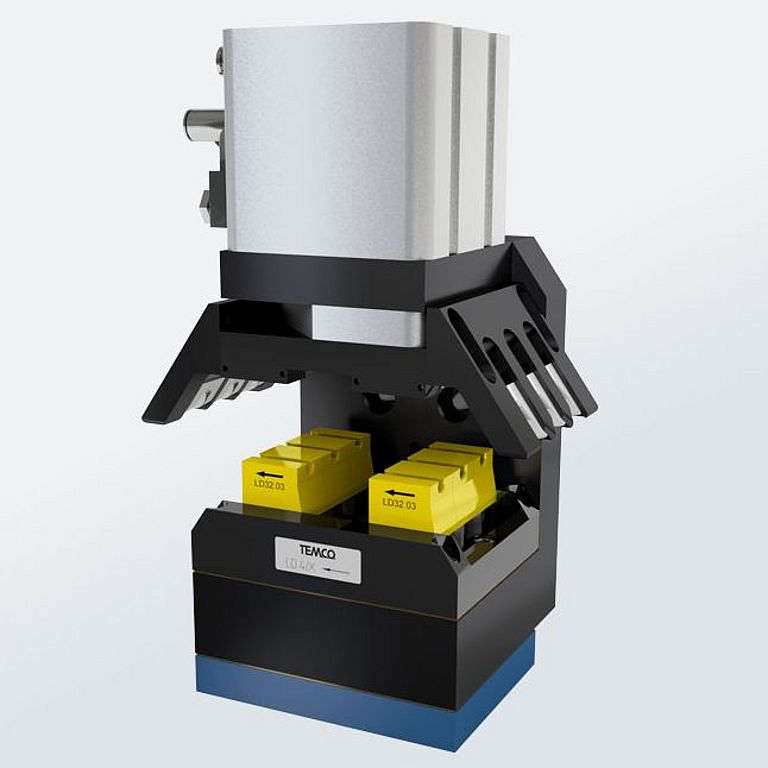

Temco's air interlacing jets are suitable for all textile processes and various applications, providing both a productivity increase and high yarn quality.

State-of-the-art quality control ensures a continuously high-quality standard which is of paramount importance for products used in large numbers.