Around 110 million tons of fiber were processed around the world in 2023, mainly for clothing, technical textiles or home textiles. Fiber consumption is growing with the world population and disposable income, on average between two and three percent per year.

Rieter Business Model

Yarn production

The process from fiber to textile begins with fiber production. A yarn is produced from the fibers, for example from cotton, linen, polyester or viscose. A textile is then produced from the yarn via various processing steps such as weaving, knitting, dyeing or finishing.

Yarn is produced in two basically different ways. On the one hand, this is done by spinning staple fibers. These are fibers with a staple length of 23 to 60 mm (short-staple fibers) or over 60 mm (long-staple fibers). On the other hand, yarn is produced by processing so-called filaments to make continuous filament yarn. The yarns resulting from filaments have different properties than those produced from staple fibers. In the clothing industry, the yarn produced from staple fiber predominates because it offers pleasant wearing comfort. Each of the two types of yarn production accounts for around 50 percent of world fiber consumption.

Rieter is mainly engaged in yarn production from staple fibers. The most important of these in 2023 were cotton (about 25 million tons), polyester (about 18 million tons) and viscose (about six million tons).

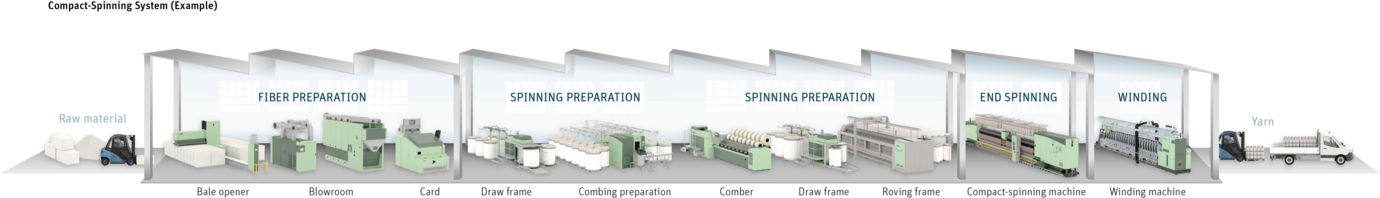

The process for producing a yarn from staple fibers consists of three stages: fiber preparation, spinning preparation and end spinning.

In fiber preparation, the fibers, which are delivered in bales, are separated, cleaned if necessary, and aligned. This takes place in the process stages blowroom/opener and card. Spinning preparation involves the homogenization and drawing of the sliver. The machine required for this is known as the draw frame. In cotton processing, the comber also plays a role: here, short fibers are combed out in order to produce a higher quality yarn. By the end of the spinning preparation stage, a uniform sliver or roving has been produced.

Spinning process

In the end-spinning stage, the fiber mesh is further drawn (up to about 40 fibers in cross-section for very fine yarns) and spun into a yarn by twisting. Twisting takes place either by means of a rotating spindle (ring spinning, compact spinning), by rotation of a rotor (rotor spinning) or by an air flow (air-jet spinning). Compact spinning is a variant of ring spinning that uses an auxiliary device to achieve yarn with a higher density as a result of improved fiber integration.

After spinning, imperfections are removed from the yarn. The yarn is then wound on a package, in order to present it in a suitable form for the subsequent process steps in the textile production chain.

Measured variables for capacity

The production capacity for producing yarn from staple fibers is measured in spindle equivalents. The production capacity of a ring spindle serves as the basis. The spinning unit of a rotor spinning machine corresponds to the productivity of five to six ring spindles, whereas that of an air-jet spinning machine corresponds to the productivity of 20 ring spindles.

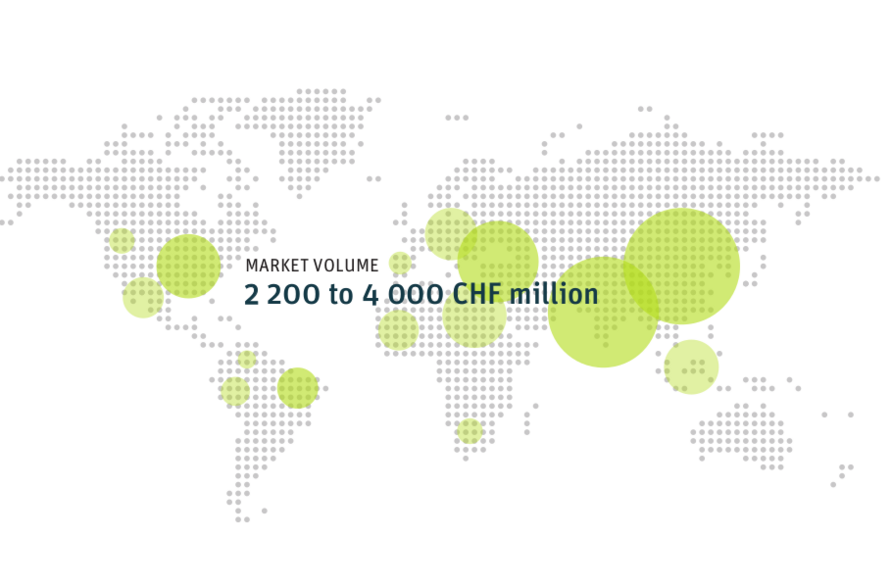

A total of more than 250 million spindle equivalents worldwide were used in 2023 to produce yarn from the around 60 million tons of staple fibers, of which around 95 million are in China, 63 million in India, 73 million in the Asian countries (excluding China, India and Türkiye) and 14 million in Türkiye. Every year, between 11 and 13 million spindle equivalents are installed on average. Rieter delivered 2.31 million spindle equivalents (2022: 2.56 million) in 2023. In addition, spinning mills require consumables, wear & tear and spare parts for ongoing operation.

Market

The world market for staple fiber machines, which is relevant for Rieter, has an annual volume of CHF 2 200 to 4 000 million. Rieter is the market leader with a market share of around 30 percent.

Business with new machines, consumables, wear & tear and spare parts

The business with new machines is cyclical. The tendency to invest in the spinning industry is mainly influenced by expectations regarding fiber consumption and the margins that can be achieved by selling yarns. Fiber consumption is dependent on the economy, while the margins for yarn depend on the movement of raw material prices, capacity utilization and the production costs of the spinning mills as well as foreign exchange rates and are influenced by government policies.

The business with consumables, wear & tear and spare parts is much less cyclical. The basic business is driven by the degree of capacity utilization of spinning mills – operational spinning mills require consumables, wear & tear and spare parts. Project business such as the conversion or modernization of entire spinning mills, on the other hand, are subject to the investment cycle described above.

Product and service offering

Rieter plans spinning mills, develops, produces and supplies the machines for fiber preparation, spinning preparation and end spinning, and supervises the installed machines throughout their life cycle.

Rieter with all its brands is established worldwide as a premium supplier. Innovative products and services from Rieter enable spinning mill operators to be more competitive. Success factors are either low yarn production costs, which are achieved through savings on raw materials, energy, labor and productivity advantages and therefore enable a sustainable yarn production, or special yarns, which allow higher prices to be achieved.

The professionalism and availability of the service is also a key aspect when customers decide to buy Rieter solutions.

The three business groups

The Business Group Machines & Systems develops, produces and distributes new equipment as spinning systems or as single machines. Blowroom and cards are used for fiber preparation; draw frames, combers and roving frames are used for spinning preparation; and ring, compact-, rotor and air-jet spinning machines as well as winding machines are used for end spinning. The offer is supplemented by planning services and automation solutions as well as ESSENTIAL, the digital platform for the complete spinning mill.

The Business Group Components develops, produces and distributes technology components and precision winding machines as well as solutions for the production of filament yarns and nonwoven fabrics. Technology components come into contact with fibers and affect yarn properties; they are used in new machines and have to be replaced at regular intervals during operation.

The Business Group After Sales develops, produces and distributes spare parts for Rieter machines as well as building conversions and modernizations. After Sales also sells technology components that are not included in the range of products offered by the Business Group Components. After Sales also offers services that enable Rieter customers to improve the efficiency and effectiveness of their spinning mills.