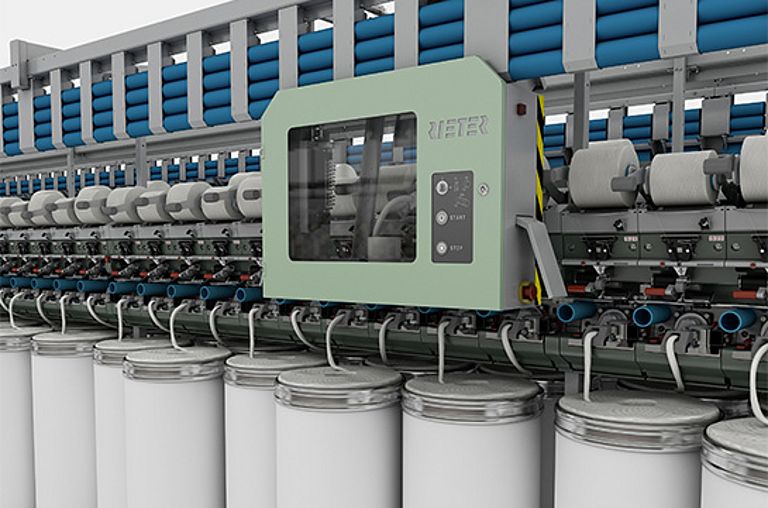

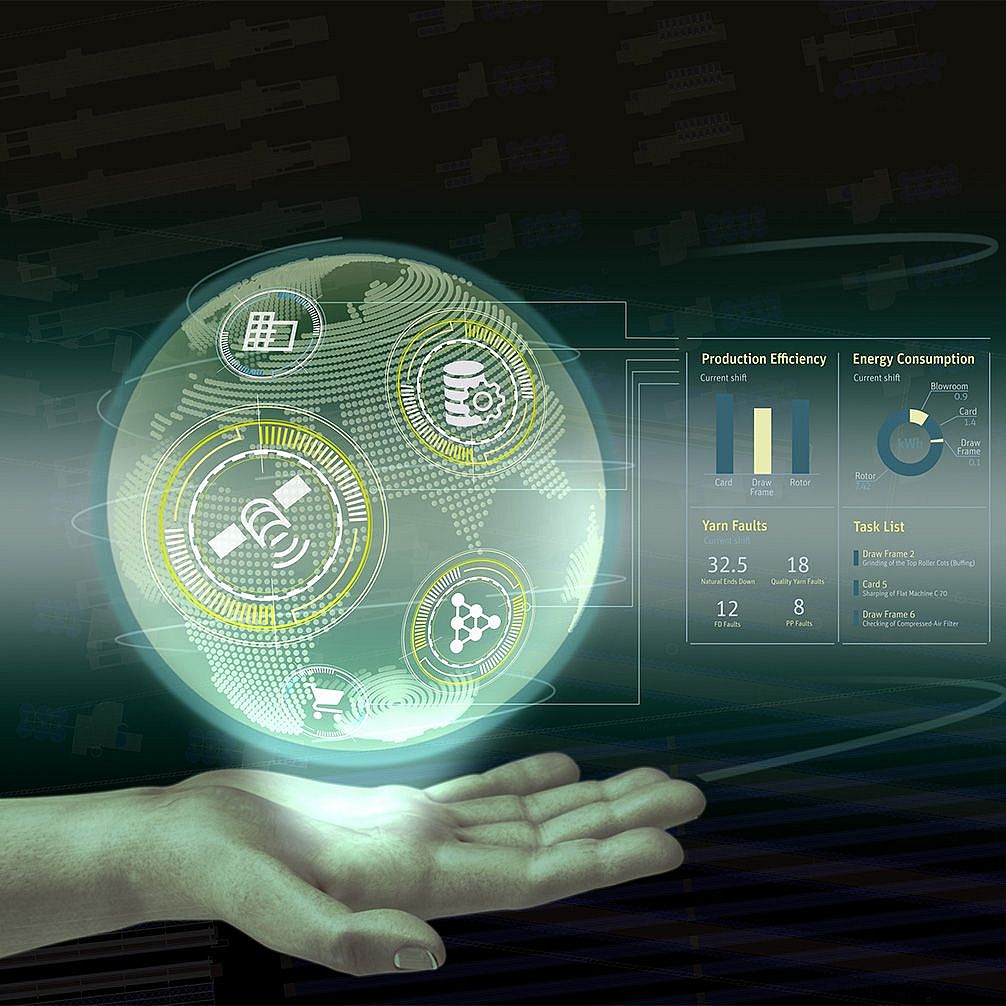

Customized solutions

As a system provider, Rieter knows the automation and logistics requirements for spinning-mill systems inside-out. For complete installations, the efficiency of various automated systems can be evaluated with specific reference to the customer and country. Rieter devises and provides sophisticated solutions, tailored exactly to customer requirements and the size of the customer’s operation.