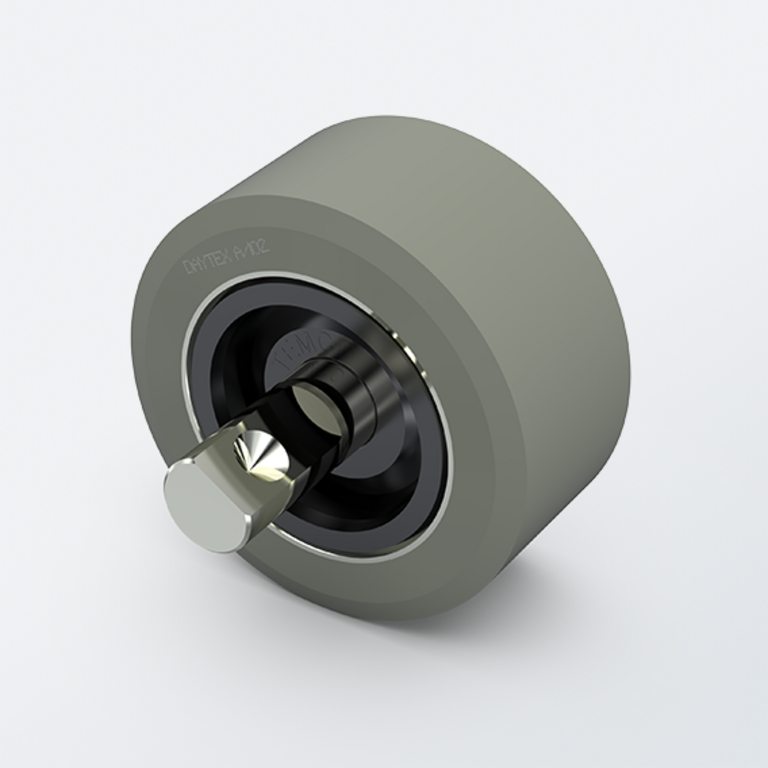

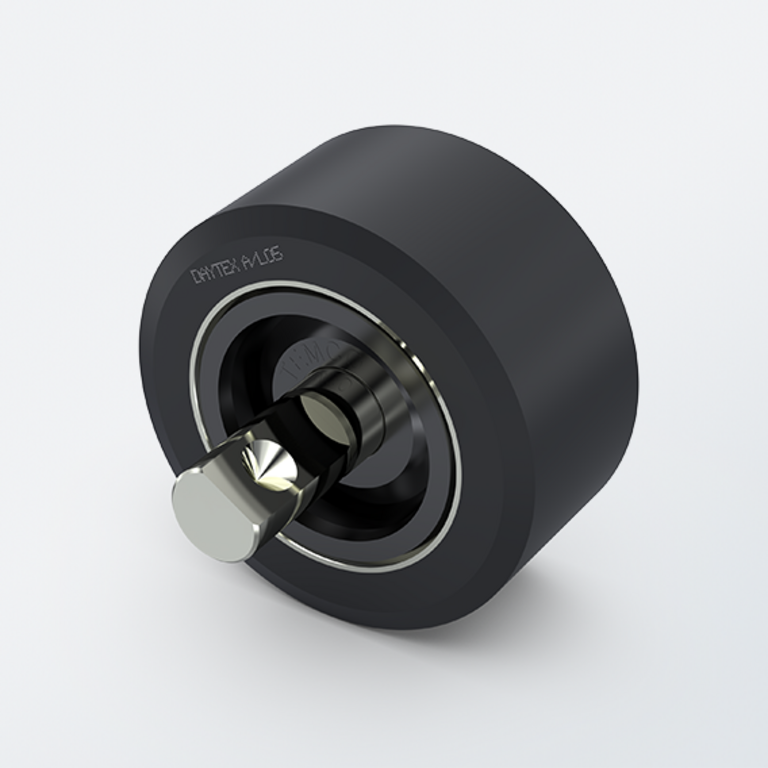

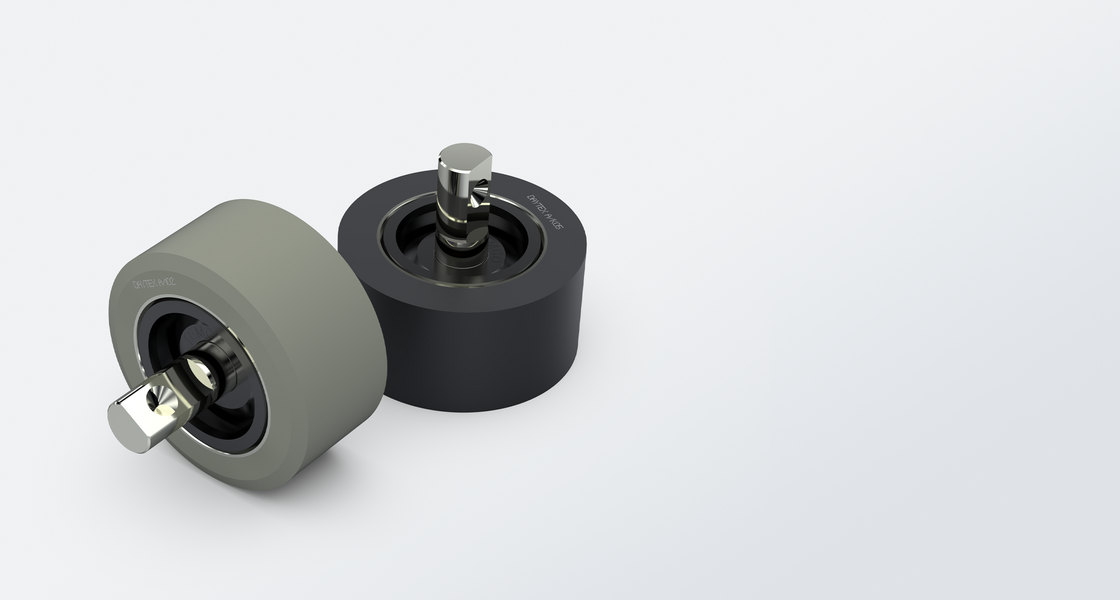

Nip Rollers LR

For outstanding yarn quality- Universal application

- Superior lifetime

- Highest quality standards

Modern false twist texturing (DTY) machines are equipped with up to four nip roller feeds per texturing position. Nip rollers have a major impact on the drawing process and therefore exert a direct influence on the quality of the textured yarn. Temco nip rollers also ensure a dramatic reduction of power consumption while maximizing competitiveness.

Nip rollers serve to press continuous material like textile yarn or glass fibers onto a feed shaft during the manufacturing process. This creates frictional locking which guarantees an uniform and gentle drawing of the yarn.

Features

- Excellent radial run-out

- Compact construction due to the integrated raceways

- Low friction moment and thus significant energy savings

- Rotational speeds up to 2,000 m/min

- Maintenance-free due to lifetime lubrication

- Possibility to use different covers

- Gentle yarn treatment

Advantages

- Outstanding wear and crack resistance, excellent oil, chemical and heat resistance

- Designed to meet the highest demands on all fibers and working conditions for all common and high speed texturing machines

- Long lasting durability and easy handling, ensuring higher productivity

- Better thread clamping force on the yarn. Enabled by the higher contact pressure

- Constant form against the drive shaft due to lower concavity minimizes light leakage

- Lower vibration level at high production speeds

- Less deformation during regrinding

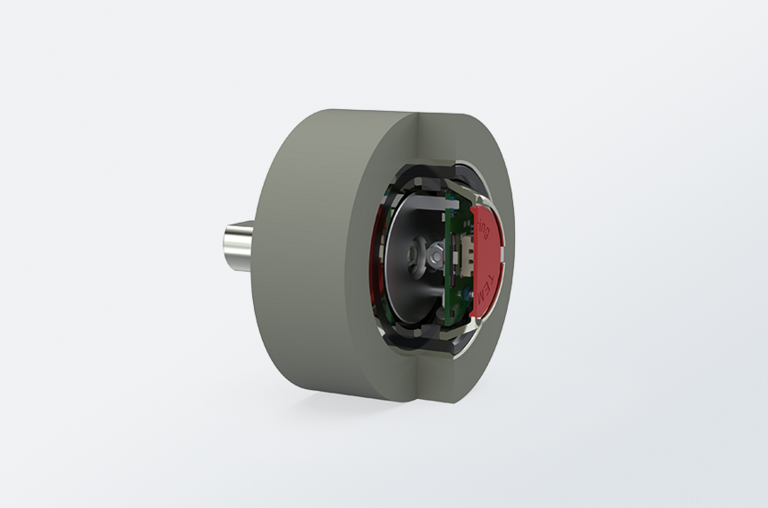

LR & i-Bearing

The monitoring system i-Bearing is now available for the Temco Nip roller LR.

The intelligence of the i-Bearing allows the constant condition monitoring of every single Temco bearing installed within a plant. By measuring speed, vibration acceleration and temperatures, the i-Bearing identifies critical conditions allowing bearings to be replaced before they fail. Machine maintenance is thus optimized and expensive downtime minimized. Customers also get a clear overview, 24/7, of the condition of all installed Temco bearings across their entire plant.

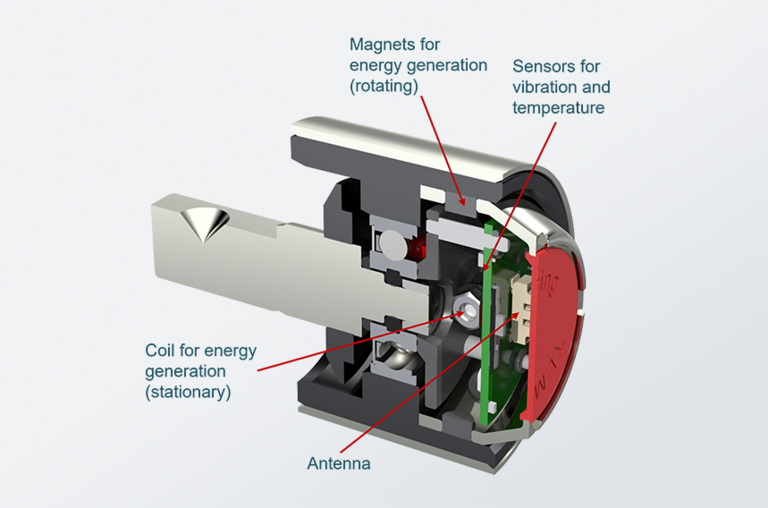

Design and functions LR7035 with i-Bearing

Wireless condition monitoring

Sensors and power supply integrated directly into the bearing

Measurement of speed, bearing vibrations and temperature

No external power supply or battery required as the energy is self-generated

Energy supply via rotating cap with integrated magnets in combination with stationary coil

Measurement directly on the inner ring of the bearing

Adaptable to various TEMCO bearings