VARIOline简介

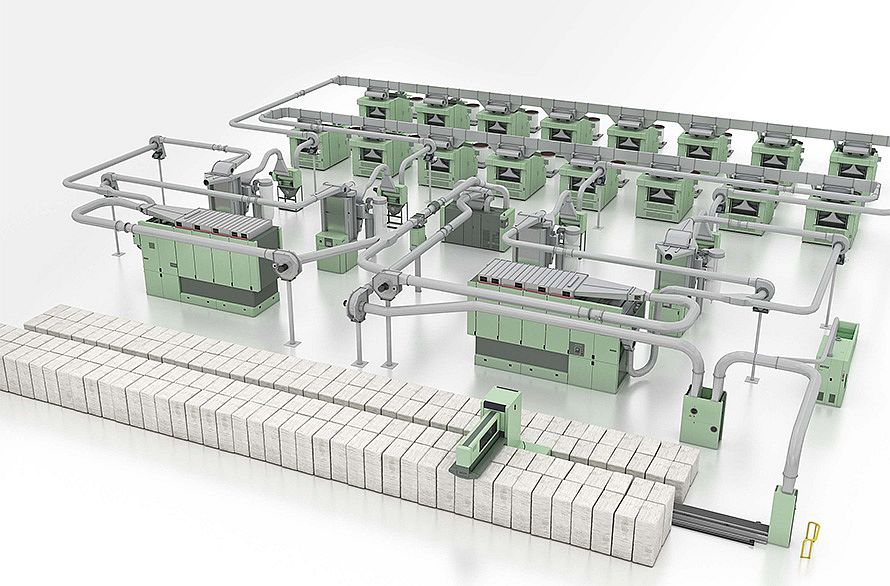

VARIOline柔性开清理念,能实现效果最佳的纤维开清。这可确保最高的纱线质量水平。生产线产量达到2 400kg/h情况下,所有开清设备都具备良好的运行性能 。

与其他提供商的解决方案相比,VARIOline柔性开清流程可节能约40%。细小棉束、VARIOset功能,渐进式等开清工艺技术,可比其他开清系统节约1%的原料。

VARIOline柔性开清理念,能实现效果最佳的纤维开清。这可确保最高的纱线质量水平。生产线产量达到2 400kg/h情况下,所有开清设备都具备良好的运行性能 。

与其他提供商的解决方案相比,VARIOline柔性开清流程可节能约40%。细小棉束、VARIOset功能,渐进式等开清工艺技术,可比其他开清系统节约1%的原料。

生产线产量达到2 400kg/h情况下,所有VARIOline开清设备都具备良好的运行性能。细小棉束、渐进式开清、VARIOset灵活工艺设置等工艺技术大大提高原料利用率。与其它解决方案相比,VARIOline柔性开清开清线可节能约40%。

柔性开清是成就最佳纱线质量的关键。将原料开松成细小棉束,确保了后续工序高效开清和去除微尘。得益于独特的三点混棉工艺,纤维均匀混和。纱线质量确保长期稳定。

VARIOset功能一键设定,适应多种原料。几款标准机器、各类除杂和开松模块组合成各种清花流程,满足客户各种定制需求。工艺配置灵活,适应小批量生产,混开棉机(自动或人工喂棉)是小批量多品种的理想选择。

VARIOline ECOrized气流自动平衡系统让我们欣喜不已。它彻底改变了我们的运营,使其更加高效和环保,同时也为我们的员工营造了更好的工作环境。技术总监Alam Zeb Burki, Sapphire Textile Mills Ltd.

这两种系统核心设计理念一致,均致力于实现高纤维质量、连续物料流和优化除杂。主要区别在于能效:

VARIOline柔性开清:相较于传统的开清生产线,该标准配置得益于间歇式除杂技术、高效节能的驱动和优化的产线布局,已实现显著节能效果。

VARIOline柔性开清ECOrized清花气流自动平衡系统:该系统为VARIOline柔性开清系统的能效优化版。借助先进的气流控制、优化的管道布局和高效的风机系统,该系统将原料输送的能耗降低达30%。ECOrized清花气流自动平衡系统在降低运营成本和减轻环境影响的同时,可保持同等的除杂性能和产能。

区别于传统系统,VARIOline将连续物料流与智能气流管理和流线型机器布局相结合,从而可减小纤维应力并降低能耗。此外,该系统采用先进的除杂技术,可在保持纤维长度的同时确保最大程度的除杂,从而能够提高纱线质量并减少落杂。

VARIOline具备高适配性,可加工棉花、化纤和混纺原料,包括再生原料。系统配置灵活可调,适用于各种纤维类型和纺纱应用,助力纱厂在生产不同质量的纱线时保持灵活。

根据所选配置和纤维类型,VARIOline可实现高达2 400千克/小时的产能,同时保持稳定的质量。高吞吐能力支持大规模运营,同时不影响除杂效率或纤维完整性。

VARIOline采用模块化设计,使纱厂能根据生产目标、纤维类型和可用空间定制生产线。设备可采用适应不同布局的布置,系统可轻松扩展和调整,以适应未来的要求,这使其成为纱厂的长期投资。

由于世界人口的增长和生活水平的提高,纺织品消费不断增长。麻纤维等天然纤维成为最常用的纺织品生产原料(例如,涤纶和棉)的可持续替代选择。立达为在短纤纺纱工艺和后道纺纱工艺中生产麻纤维提供定制、经济的解决方案。