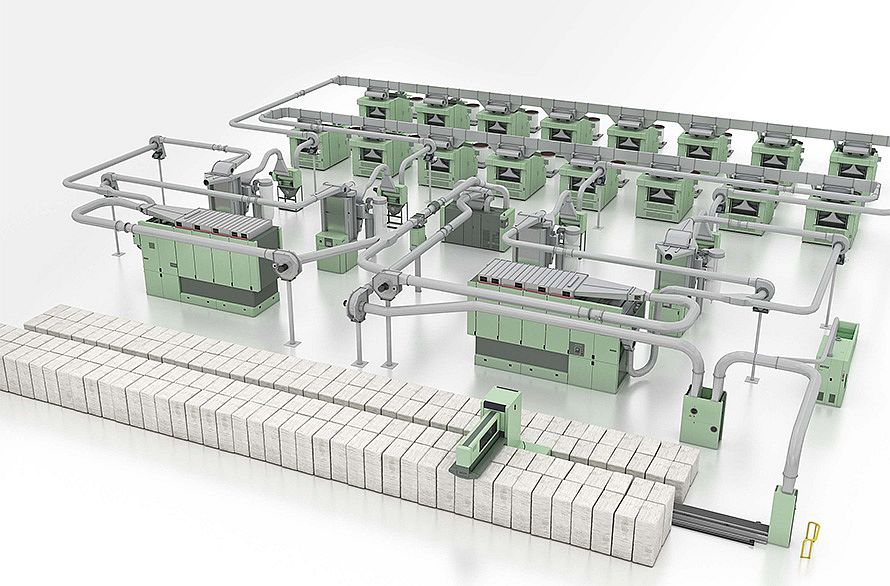

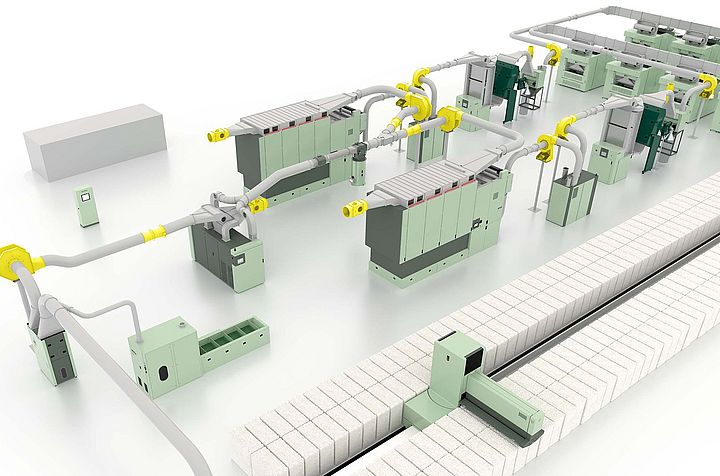

Introducing VARIOline

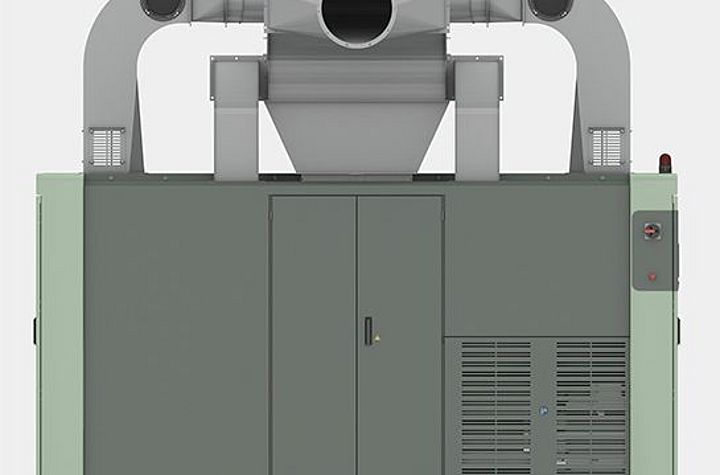

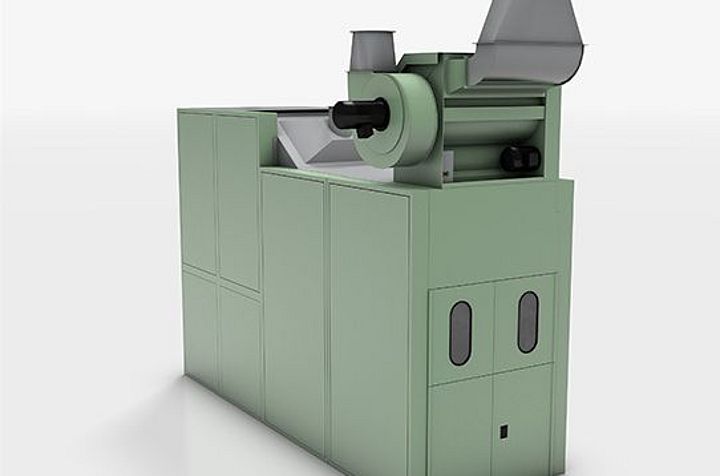

The blowroom line VARIOline is the variable concept for optimally opening and cleaning fibers. This guarantees the highest level of yarn quality. All blowroom machinery is designed to support an impressive line production performance of up to 2 400 kilograms per hour.

VARIOline consumes around 40% less energy than solutions from other providers. The optimum combination of microtufts, the VARIOset function and progressive cleaning delivers a 1% raw material saving compared with other systems available on the market.

Additionally, the optional intelligent software ECOrized, can further reduce energy consumption in fiber transport by 30%.