RSB-D/SB-D 55简介

这款新一代单眼并条机可满足最多样化的需求,为其提供最佳解决方案。这款机器使纱厂能够达到极高的质量和效率,在加工再生纤维时也同样出类拔萃。全新高度的耐用性可保持低成本运营。

卓越的检测精度和最高自调匀整动力学性能,都确保了卓越的棉条均匀度(这是生产高品质纱线的理想先决条件)。10英寸触摸屏集成了棉条专家系统SLIVERprofessional,并包含用于再生纤维的推荐设置及其他重要参数。

这款新一代单眼并条机可满足最多样化的需求,为其提供最佳解决方案。这款机器使纱厂能够达到极高的质量和效率,在加工再生纤维时也同样出类拔萃。全新高度的耐用性可保持低成本运营。

卓越的检测精度和最高自调匀整动力学性能,都确保了卓越的棉条均匀度(这是生产高品质纱线的理想先决条件)。10英寸触摸屏集成了棉条专家系统SLIVERprofessional,并包含用于再生纤维的推荐设置及其他重要参数。

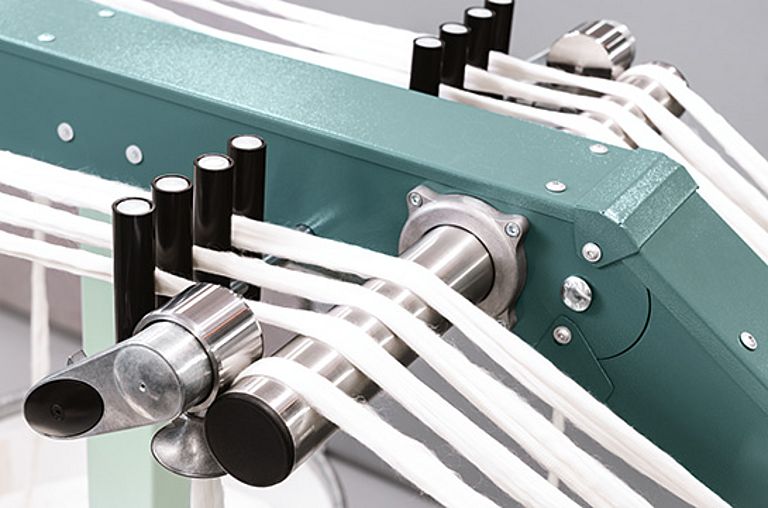

终身免润滑的皮辊轴承和增强的导条架结构等特点再次提高了机器的耐用性。可保持低成本运营。ECOrized驱动概念可确保低能耗。

棉条堵塞矫正程序(仅限RSB)可避免圈条器中出现棉条堵塞。这减少了操作工作量,并在后道工序中保持高效率。

圈条器CLEANcoil-PES可将难加工涤纶纤维的清洁周期延长至少100%。圈条器对含有40%以上再生涤纶的混纺也有益处。

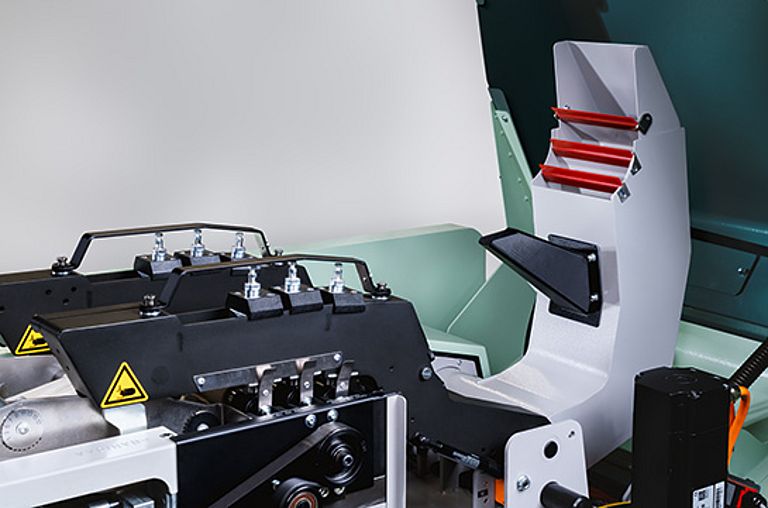

RSB-D 55卓越的检测精度和最高自调匀整动力学性能确保了卓越的棉条匀整度。SB-D 55还可选配久经应用验证的立达质量监测系统(RSB上的标配)。选配的条筒清洁装置CLEANtube确保在加工棉条时,实现了清洁的圈条。

通过扩展的吸风系统和新颖的网状漏斗设计,并条机可增强对再生纤维的加工能力。棉条专家系统SLIVERprofessional可提供再生纤维的推荐设置。

其他选配方案可在机器停止/启动时提供恒定的棉条抱合力。因此,在加工精梳棉的过程中,避免了粗纱机导条架上的意外牵伸和纱线中细节。

10英寸机器显示屏和改进的菜单导航,将用户易用性提升到了新高度。高清晰度的LED屏能够显示并条机的运行状态,简化挡车工的工作。

利用变频控制驱动可在显示屏上便捷地设置出条速度、圈条速度、吸风强度和牵伸倍数(仅限RSB)。

棉条专家系统SLIVERprofessional现在还包括圈条速度、条筒台速度等附加的重要设置参数,以实现快速换批和卓越品质。

我们在精梳棉紧密纺过程中依托立达并条机,恪守生产优质纱线的承诺,从而在生产过程中树立了卓越标杆。Global Textile Infinity公司总经理Otabek Nishanov

借助立达单眼并条机,我们提高了产能和质量,我们很重视其在各种原料和混纺原料之间切换时的灵活性。Apparel Guatemala的生产经理Maria Felix Villeda

| 范围 | RSB-D 55 | SB-D 55 |

|---|---|---|

| 原料 | 纤维长度小于等于60毫米的棉纤维、化纤、混纺纤维 | |

| 并合 | 可达8并 | 可达8并 |

| 喂入棉条 | 12 – 50 千特克斯 | 12 – 50 千特克斯 |

| 牵伸 | 4.0 – 11.6倍 | 4.5 – 11.6倍 |

| 输出棉条定量 | 1.25 – 7.00 千特克斯 | 1.25 – 7.00 千特克斯 |

| 范围 | RSB-D 55 | SB-D 55 |

|---|---|---|

| 出条 | 1 | 1 |

| 出条速度 | 最高1 200米/分钟 | 最高1 200米/分钟 |

RSB-D 55/27 helps you maintain superb sliver and yarn quality even when processing recycled fiber blends. It supports reliable running with setting guidance from SLIVERprofessional, an enlarged suction concept, a minimum bottom-roller distance and a novel web funnel design—so you can process recycled fibers more efficiently with fewer quality compromises.

The expert system SLIVERprofessional helps your operators set up the machine quickly for material changes and keep quality consistent across shifts. It provides additional setting parameters and supports spectrogram fault analysis (such as periodic faults and draft waves), enabling faster root-cause correction and higher machine availability.

The Rieter Quality Monitor (RQM) helps you avoid producing faulty sliver by continuously monitoring delivered sliver thickness and stopping the draw frame automatically if defined limits are exceeded. It works independently of the autoleveling unit via a movable calender disc roll, and quality data can be connected to ESSENTIAL for more advanced analysis.

CLEANtube is a patented intelligent control system for the coiler drive. It prevents trash particles and short fibers from accumulating in the sliver tube, reducing manual cleaning and sliver waste. This optional feature saves work when removing deposits and helps avoid defect points at the draw frame head—supporting high efficiency in downstream processes and stable yarn quality.

The coiler jam straightener helps prevent downtime by clearing potential sliver jams and avoiding sliver breaks. Using the single-motor-driven coiler concept, it reduces operator intervention and keeps efficiency high at the autoleveler draw frame and in downstream processes.

RSB-D 55 supports more sustainable production by reducing material loss and energy consumption while maintaining productivity. It combines solutions such as CLEANtube, optimized suction, a sliver coiling sensor and the ECOrized energy-saving drive concept—helping you lower waste and operating costs.