Autoconer X6简介

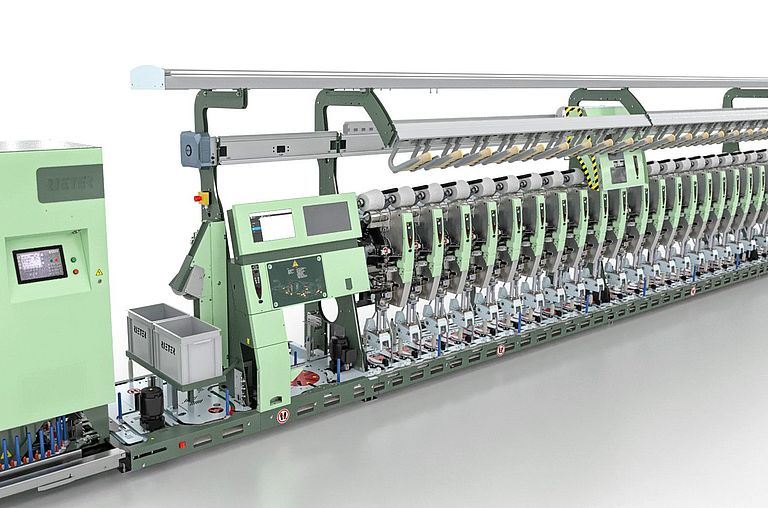

自动络筒机Autoconer X6代表着高效、优质和高度灵活。能耗极低,树立了络筒的标杆。定制自动化,以及采用RFID技术的智能物料流,使自动络筒机Autoconer X6非常适合现代化纱厂。新型换管装置再次实现更灵活的自动化。

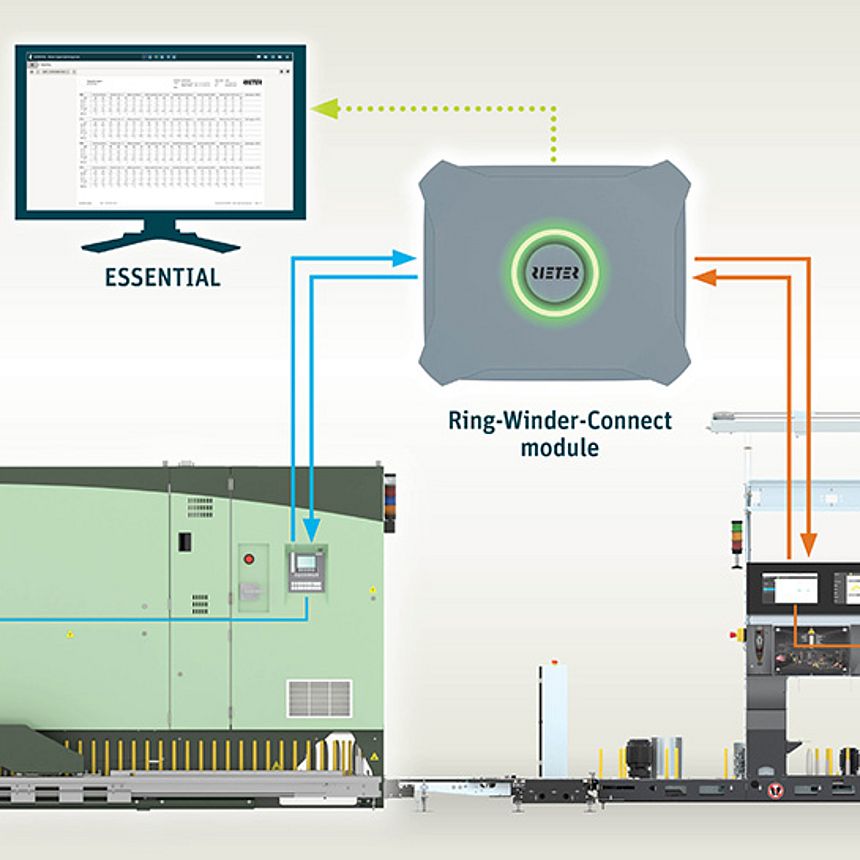

立达细络交互模块Ring-Winder-Connect支持实时数据分析,确保过程可靠性、更出色的系统集成与稳定的质量。紧凑的人体工学设计,最大限度地提高操作舒适度。自动络筒机Autoconer X6无论是在常规还是高端应用场景中,均实现优异的筒纱质量,开放式捻接块技术可确保出色的捻接品质。