C 81简介

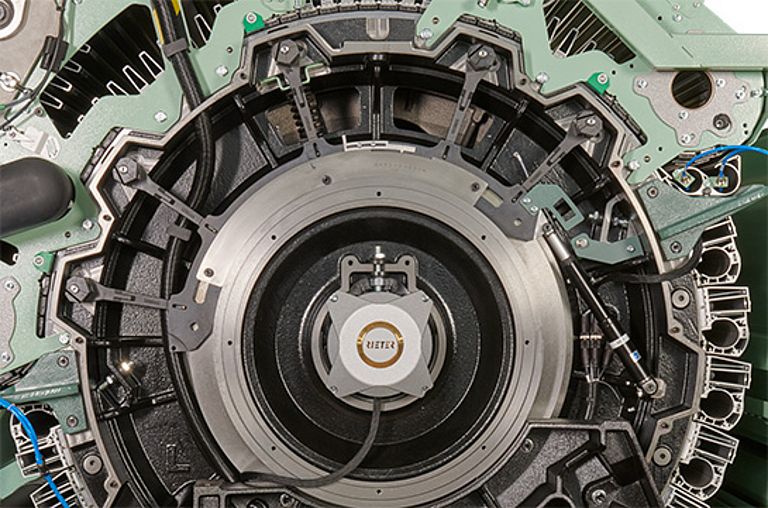

由于采用了人工智能技术,C 81是目前市场上有效工艺梳理面积最大的梳棉机。梳棉隔距控制功能确保了隔距在任何情况下都处于最佳距离,从而充分释放40根活性盖板的潜力。与市场上任何其它竞品相比,梳棉机C 81的生产能力提升高达40%,且生条质量优异。

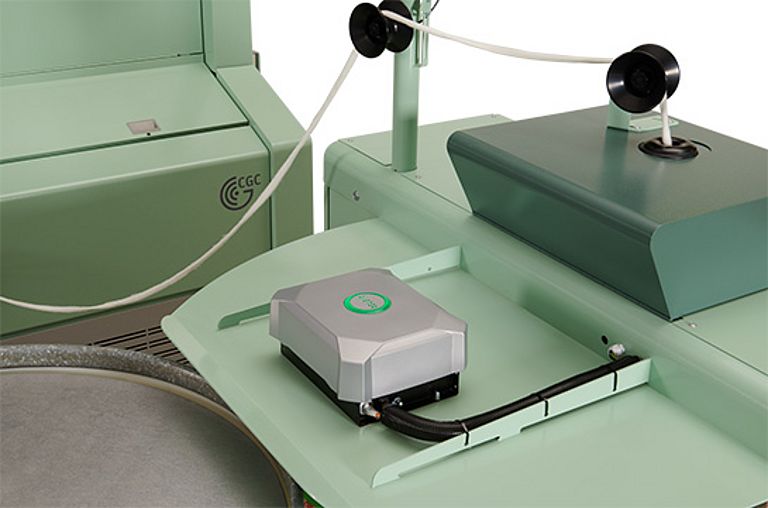

独特的杂质水平监控功能,保证了杂质始终处于控制之下,优化了纤维输出。梳棉机进口和圈条节段中的传感器会实时监控原料质量。

不仅如此,C 81是目前市场上能效比最高的梳棉机,从而节约了宝贵的能源。

由于采用了人工智能技术,C 81是目前市场上有效工艺梳理面积最大的梳棉机。梳棉隔距控制功能确保了隔距在任何情况下都处于最佳距离,从而充分释放40根活性盖板的潜力。与市场上任何其它竞品相比,梳棉机C 81的生产能力提升高达40%,且生条质量优异。

独特的杂质水平监控功能,保证了杂质始终处于控制之下,优化了纤维输出。梳棉机进口和圈条节段中的传感器会实时监控原料质量。

不仅如此,C 81是目前市场上能效比最高的梳棉机,从而节约了宝贵的能源。

有效工艺梳理区最大化为产量提升高达40%奠定了坚实基础。

得益于高产下更少的梳棉机需求数量、高能效驱动以及优化的吸风系统,实现了极低的能耗。

创新的技术截面与盖板针布HYPERTOP、杂质水平监控相结合,使原料制成率提升高达2%。

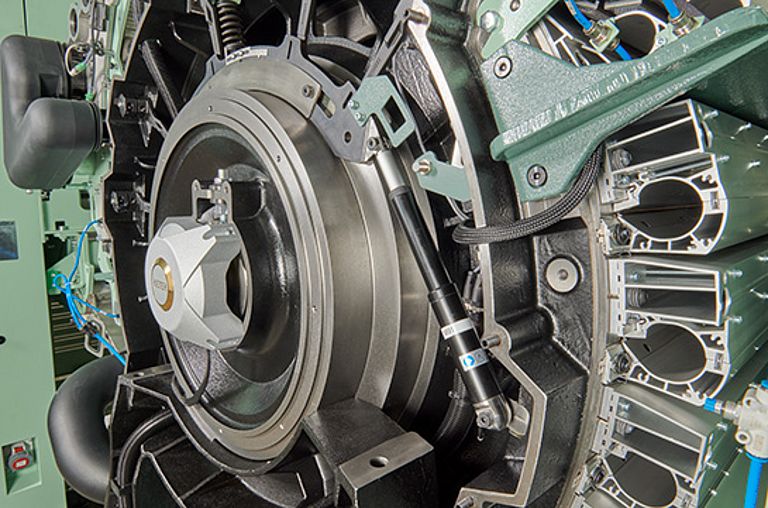

卓越的生条质量归功于40根活性盖板以及可在所有条件下实现完美的调节梳棉隔距控制功能。

杂质水平监控可以进行实时杂质分析,从而使生条质量始终处于控制之下。

集成自动磨针系统(IGS)自动在线磨针,针布始终保持锋利。这延长了针布的使用寿命,确保生条恒定地保持在高质量水平。

当机器运行条件发生变化时,梳棉隔距控制功能会独立调整设置,来确保对梳理隔距的精准把控。

杂质水平监控能够进行实时杂质分析,极速实现机器优化,以达到目标质量水平。

预梳理区和后梳理区中的一体化Q-packages以及各种插件,使其能够快速轻松地适应新原料。

相比于改造前的老款其他品牌梳棉机,单台机器的台时产量增加了220%,生条CV值更低,成纱质量更高,吨纱能耗更低。张爱云女士 潜江市昌云纺织有限公司生产负责人

| 范围 | 范围/单位 |

|---|---|

| 机器长度 | 3 440 毫米 |

| 机器宽度 | 2 450 毫米 |

| 机器重量(配标准喂棉箱) | 9 200 千克 |

| 工作宽度 | 1 500 毫米 |

| 范围 | 范围/单位 |

|---|---|

| 原料 | 棉和化纤,长度可达65毫米 |

| 产量 | 达300千克/小时 |

| 生条定量 | 4 – 12千特克斯 |

| 棉层定量 | 550 – 900克/米 |

| 范围 | 范围/单位 |

|---|---|

| 装机功率** | 33.5 千瓦 |

| 出条速度 | 达500米/分钟 |

| 压缩空气 | 0.7 标立方米/时 |

| 排风 | 1.10 立方米/秒 |

| 落棉处理 | 中央吸风,刺辊独立排杂 |

| 锡林转速 | 340 – 650 转/分钟 |

| ** 带变频器(FC),包括喂棉箱 | |

杂质水平监测器是一套智能传感器系统,可在梳理过程中实时测量落杂量。它连续监测梳理工序前后的杂质水平,并将数据提供给设备控制系统。这使得挡车工能够主动调整设置,以达到最佳除杂效率和纤维利用率。最终提高工艺透明度,减少原料浪费,即使采用不同的纤维混合物或再生原料,也能确保稳定的生条质量。杂质水平监测器可加装于梳棉机C 80和C 81上。

IGS是集成在梳棉机中的自动磨针系统。它在设备运行期间不断地对针布进行磨针,全程无需停机。这种频繁的磨针可确保针布保持最佳状态,从而确保稳定的梳理性能和生条质量。通过保持锋利的针尖,IGS可减少纤维损伤,最大限度地缩短维护停机时间,将针布使用寿命延长达10–20%。

能。C 81专为高效加工再生纤维、纱线和面料边角料而设计。它采用专业的部件和优化的纤维流,可在保持除杂效率的前提下实现柔和开松,从而成为可持续纺纱生产的理想之选。

当然可以。它采用模块化设计理念,可灵活地集成到新的和现有的生产线中,无论是立达系统,还是非立达系统。对于希望升级或扩大其梳理能力的纱厂而言,这种适应性使C 81成为具有前瞻性的投资选择。

与同级别的1.28米梳棉机相比,C 81的能耗降低达17%。这种效率得益于优化的驱动系统、降低的摩擦损耗以及以更少的梳棉机实现更高产量的能力。更低的能源成本和更小的空间要求使得C 81成为一种非常经济的解决方案。

凭借精密梳理隔距控制、先进的监测系统、优质的格拉夫针布以及可连续磨针的自动磨针系统(IGS),可保证卓越的生条质量。这些功能可实现纤维的理想开松效果、最少的棉结和稳定的条干均匀度,从而能够在后道工序中生产出高品质纱线。

自调匀整并条机RSB模块55 – 短工艺流程的新基准

梳棉机与新的自调匀整并条机RSB模块55直接连接,可减少并条机通道数并提高纺纱厂的生产效率。

RSB模块55基于久经应用验证的自调匀整并条机RSB-D 55的驱动和牵伸技术。采用全新的零接触式扫描技术,可自调匀整喂入棉条并监控生条输出情况,从而保证了更好的生条和纱线质量。如果原料或生条定量发生改变,也无需更换检测罗拉。这样提高了设备灵活性并降低了成本。

最重要的技术和工艺亮点:

为进一步实现公司目标,新投资了立达3台新型梳棉机C 80,在保证生条质量的前提下,每小时的产量可达120kg

潜江市昌云纺织有限公司近期投资了立达清梳联生产线,其中高性能梳棉机C 81显著提高了昌云的产能,并节约了能耗。

At MEM Textile from Türkiye, the C 80 card forms the basis for high-quality yarns with a remarkable production speed and outstanding sliver properties.