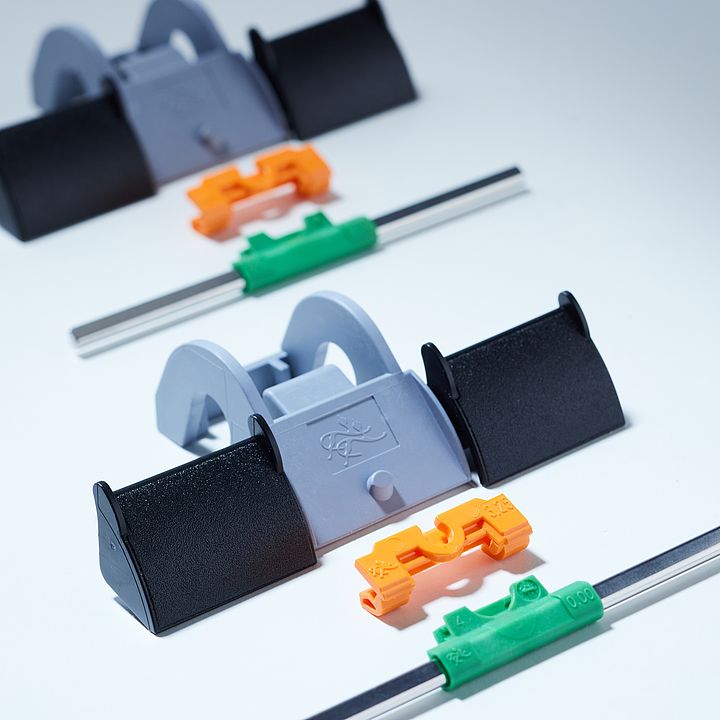

The Suessen top weighting arms HP feature a frictionless direct loading of the top rollers using plate springs.

Top Weighting Arms

Meeting the most challenging demands of high-end spinning mills- For any raw materials

- Optimum and consistent yarn quality

- Maximum drafts

FOR SHORT-STAPLE RING SPINNING

The HP-GX 3010 is for three-roller double-apron drafting systems on short-staple ring spinning machines. This top arm provides partial load relief. The HP-GX 3010 is capable of adjusting the front top roller position to meet precise technological requirements.

Characteristics:

- Any short-staple ring spinning machine with three-roller double-apron drafting systems

- All staple fibers up to 65 mm fiber length

- Drafts of up to 80 fold depending on the roving quality and the basic machine

- Support bar diameter of 28 mm

- Spindle gauges: 70/75/82.5 mm

FOR SHORT-STAPLE ROVING FRAMES

The HP 4080 is for three- or four-roller double-apron drafting systems on short-staple roving frames. The height is adjusted by an eccentric bolt, for an easier, faster, more precise and convenient setting.

Characteristics:

- Any short-staple roving frames with three- or four-roller double-apron drafting systems

- Processing of cotton, man-made fibers and blends of up to 65 mm staple length

DOWNLOADS

HP-GX 3010 – Brochure

HP 4080 – Brochure

Contact

Suessen always wants to answer queries quickly and competently. The contact page simply leads you to the respective area.