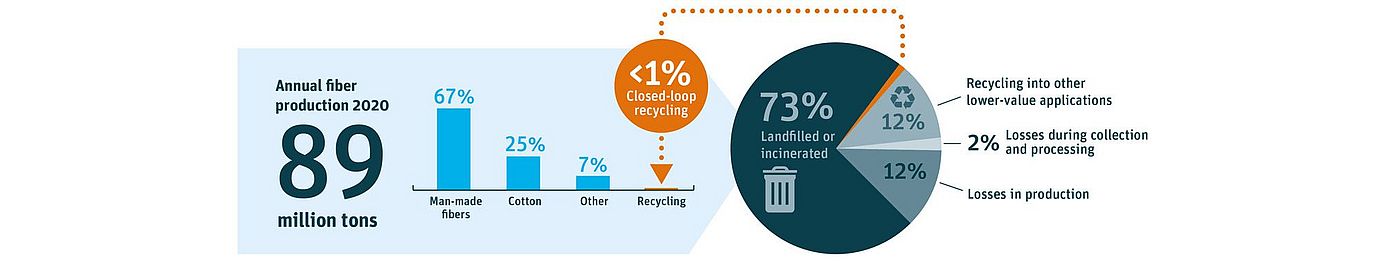

Climate change and environmental degradation are some of the main concerns facing us today. With barely 1% of garments being recycled and three quarters of the world’s clothing ending up in landfill, the textile industry is actively seeking ways to make production patterns more sustainable and pay more attention to the entire life cycle of items of clothing. Rieter uses its technological expertise to offer a complete recycling spinning system for both ring and rotor spinning lines. This enables customers to spin fibers from used garments and waste into yarns.

Com4 Recycling Spinning System

Closing the loop for good- Pushing the boundaries with Com4recycling

- Recycling systems for high-quality ring and compact yarns

- Proven rotor recycling system to maximize the share of recycled material

Recycling in textile

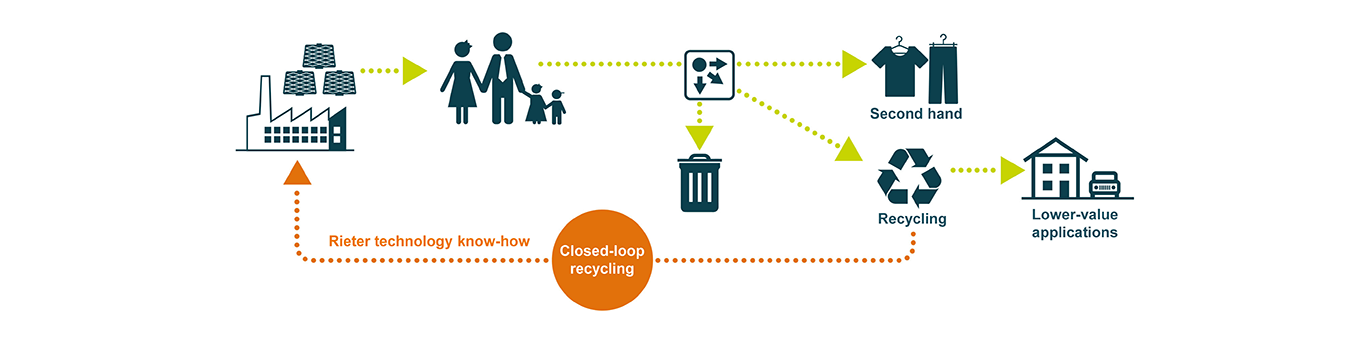

One of the goals within the textile industry is to “close the loop,” which refers to the process of recycling and reusing products without material loss – or, in other words, using less raw material and diverting waste away from landfill.

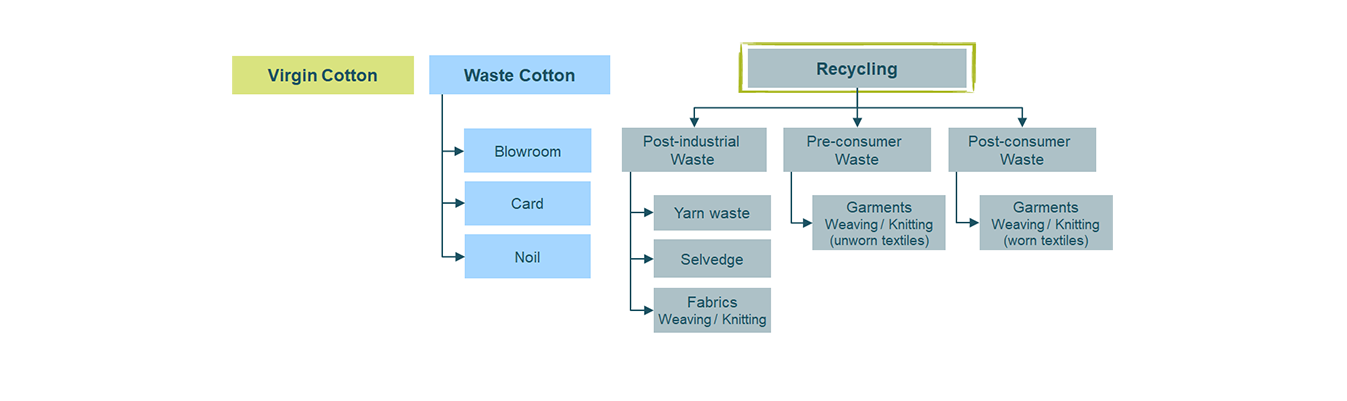

This entails solving one of today's main challenges: recycling post-industrial and post-consumer waste. Until recently, recycled clothes have been used mainly into lower-value applications. Rieter's technological know-how enables yarns of sufficient quality to be produced for use in weaving and knitting applications, thus finally allowing to close the loop in textile.

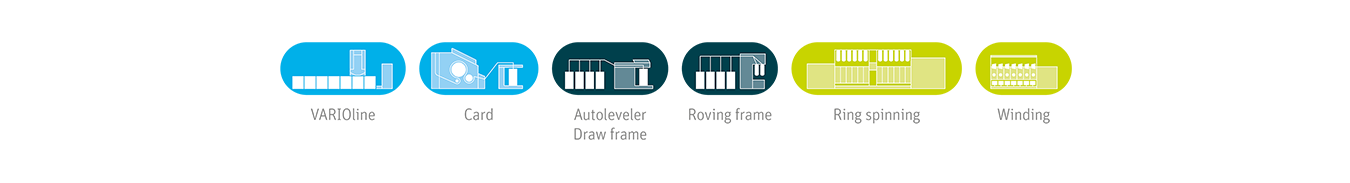

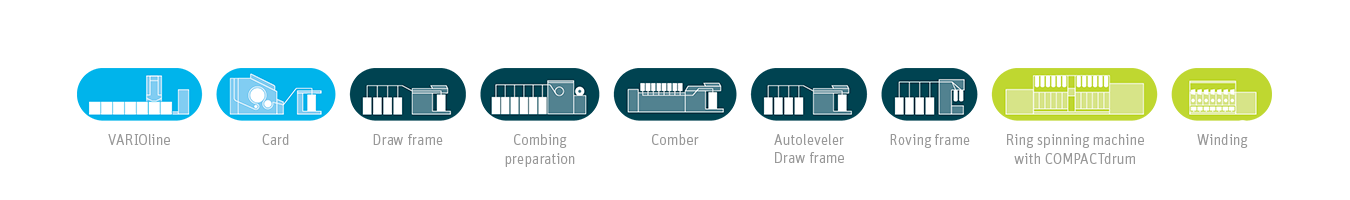

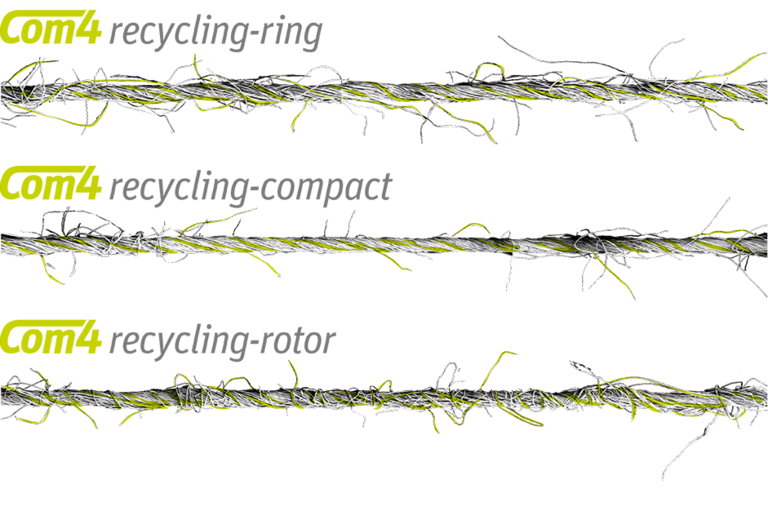

Com4recycling-ring spinning process

Rieter offers a complete ring spinning system that is designed to processing recycled fibers in the best possible way. Due to the better integration of the fibers during ring spinning, ring yarn has a higher tenacity compared to rotor spinning. This opens a wider range of applications, namely the increased use of these yarns in weaving and knitting mills.

Com4recycling-compact spinning process

The recycling compact-spinning process enables customers to produce fine compact yarns with almost 40% recycled fibers and high yarn quality from demanding raw material. The comber removes very short fibers and neps from blends of recycled and virgin cotton. This makes it possible to increase the recycled content in the blend. At the same time, both unevenness and imperfections in the yarn are improved with the use of the comber. The compacting device COMPACTdrum significantly improves the running behavior of the ring spinning machine as well as hairiness and tenacity in the yarn.

Com4recycling-rotor spinning process

Rieter has optimized the rotor spinning technology, which is naturally adapted for applications using materials with short fibers. Special geometries and options allow for optimized adaptations. The fully automated machine combines high potential for yarn tenacity with the capability to handle many ends down with excellent piecing quality. With a blend of 80% post-consumer material and 20% recycled polyester, spinning yarn up to Ne 20 is possible.

Rieter recycling classification

To help spinners work with recycled fibers, Rieter has established a recycling classification system for the typical raw-material quality available on the market. The Rieter recycling classification makes it easier for spinners to estimate what targets can be reached depending on the material. The short-fiber content, mean fiber length and 5% fiber length are important parameters after the tearing process because they determine which subsequent spinning process (ring or rotor) should be used and which quality (uniformity) and maximum spinning fineness (yarn count) can be achieved.

| FIBER KEY PARAMETRES | SHORT-FIBER CONTENT (n) | Mean Fiber Length (n) | LONG FIBER 5% | NEPS (1/g) |

|---|---|---|---|---|

Cotton short staple | 24% | 21 mm | 34 mm | 150 |

| Very good | < 45% | > 17 mm | > 31 mm | < 300 |

| Good | < 55% | > 15 mm | > 27 mm | < 600 |

| Medium | < 70% | > 12 mm | > 23 mm | < 900 |

| Poor | > 70% | < 12 mm | < 23 mm | > 900 |

Yarn licenses for Com4recycling

To further establish recycled yarns in the market, they will be included in the proven Rieter Com4 yarn family. Com4 is a globally registered trademark for yarns spun on Rieter end spinning machines. Com4recycling licenses are now available for recycled ring, compact, and rotor yarns. Spinning mills that produce recycled yarns with a Rieter card, draw frame, and end spinning machine and also have Global Recycling Standard (GRS) certification can apply for a Com4recycling yarn license.