Spinning Machinery

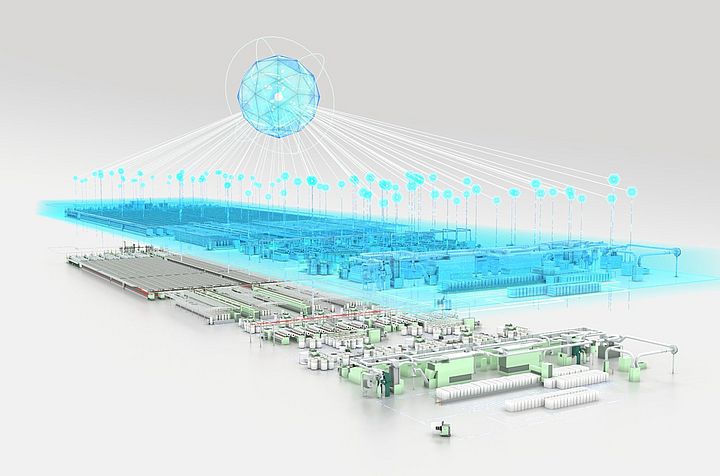

Rieter delivers cutting-edge technology for the entire yarn spinning process – from fiber preparation to winding. The portfolio covers all four established end-spinning technologies: ring spinning, compact spinning, rotor spinning, and air-jet spinning. In addition, Rieter provides advanced blowroom lines, high-performance cards, draw frames, roving frames, and precision winding machines.

Products

News and Success Stories

From Upgrade to Breakthrough: COMPACTapron Powers Rajaguru’s Growth

Rajaguru Spinning Mills increased productivity by 7% and significantly enhanced yarn quality by adopting Rieter’s compact spinning system COMPACTapron.