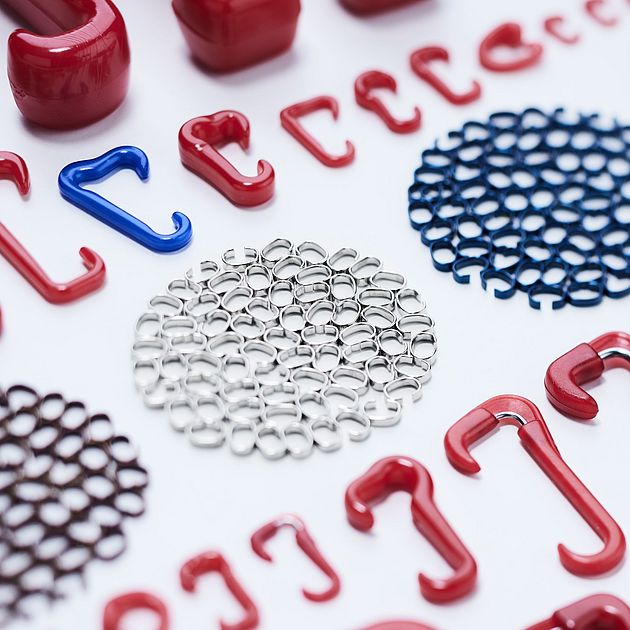

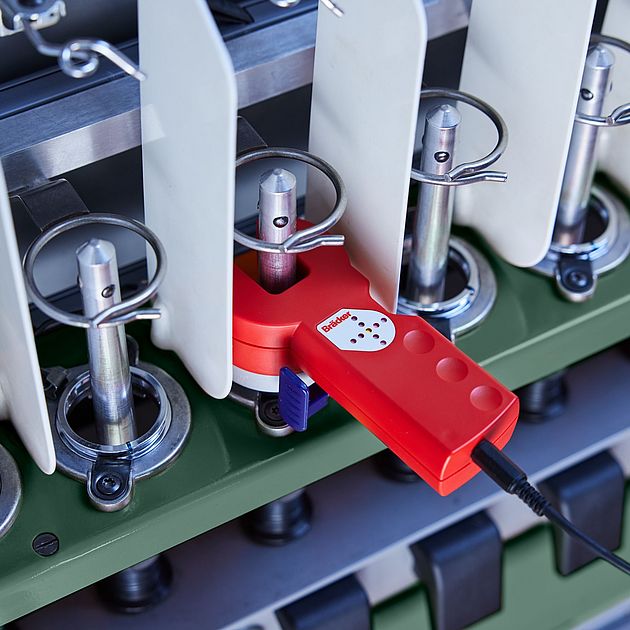

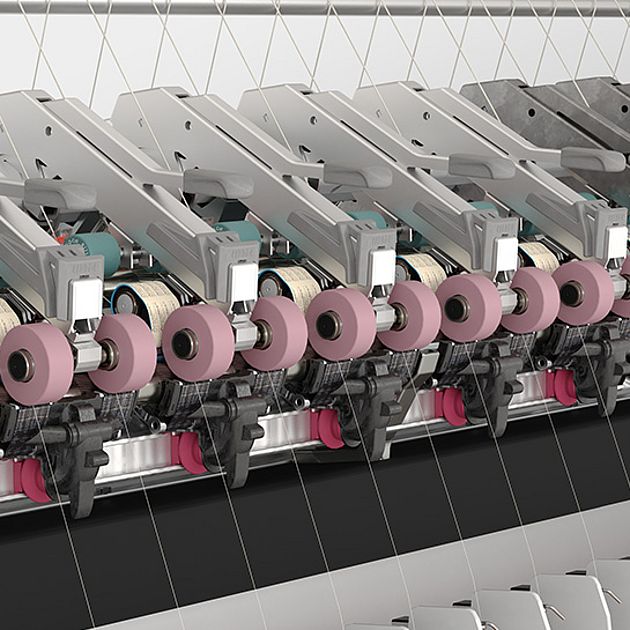

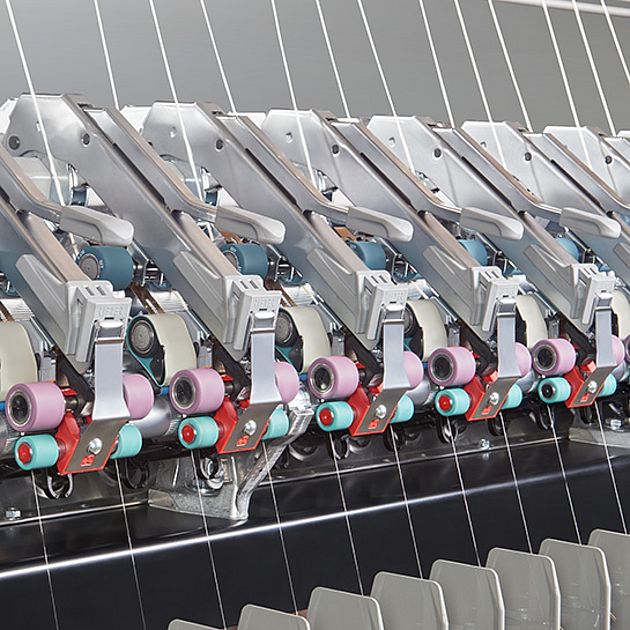

Components for spinning of short- or long-staple fibers

With years of experience in optimizing efficiency in the spinning process, the sophisticated components of Accotex, Bräcker, Novibra and Suessen are available for any type of ring and compact-spinning machine, allowing for reliable and economical yarn production.