Description

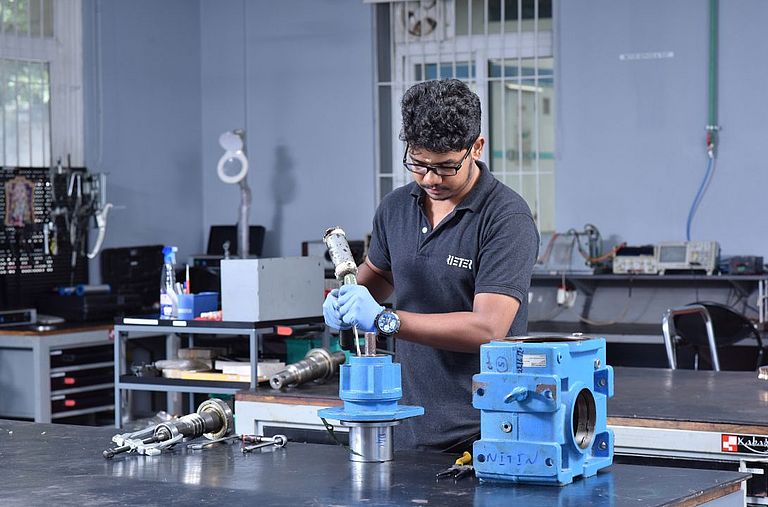

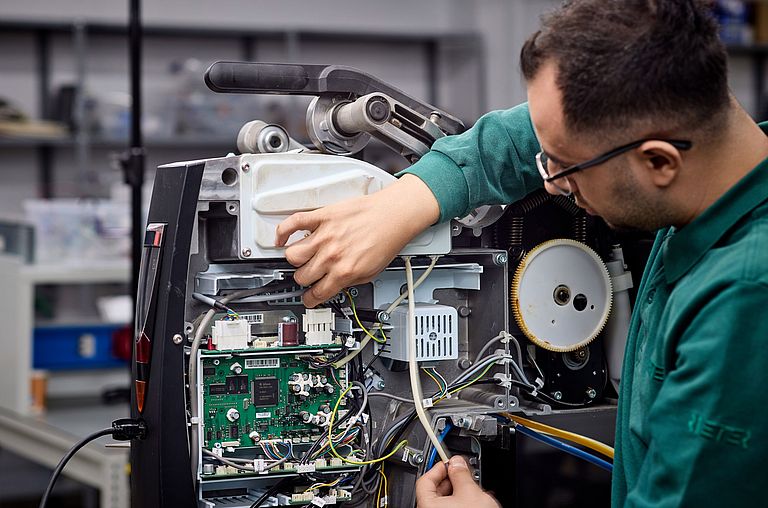

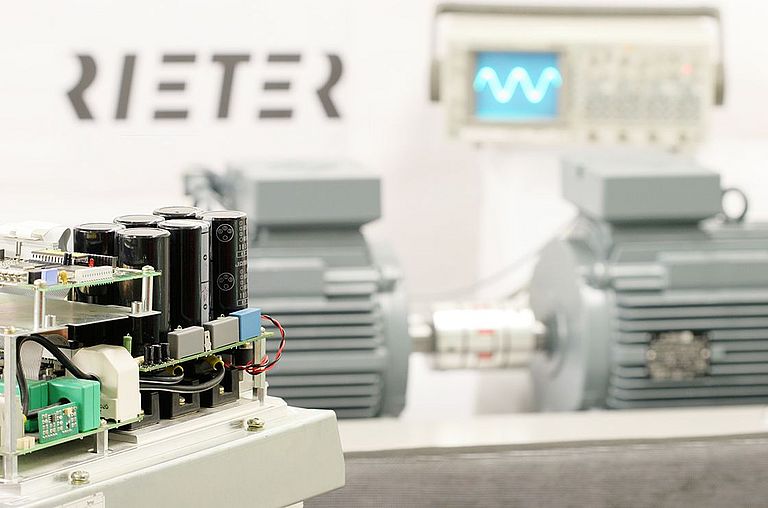

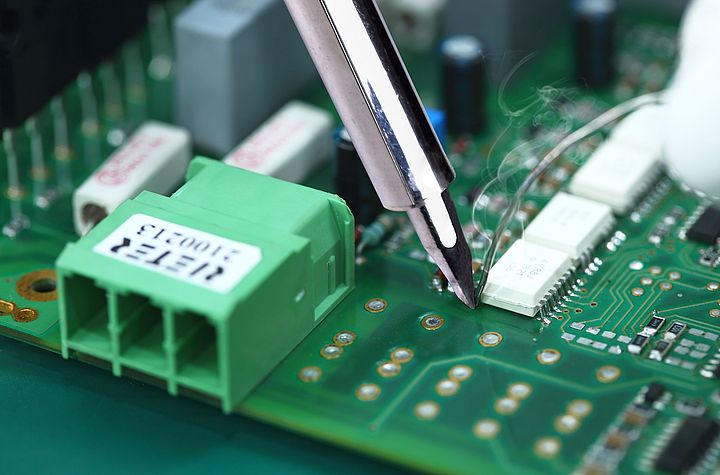

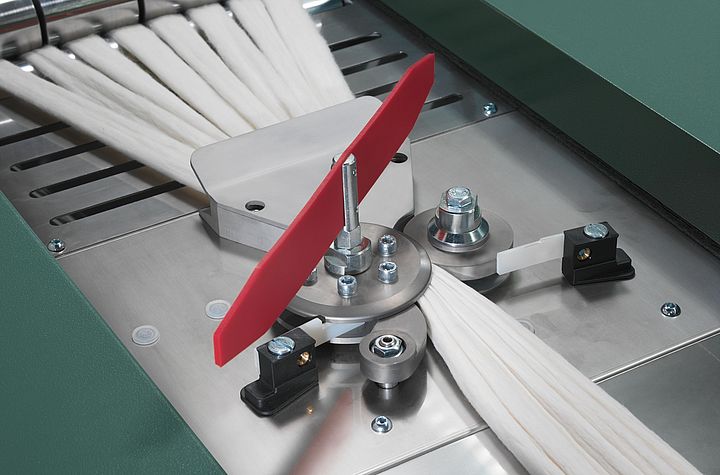

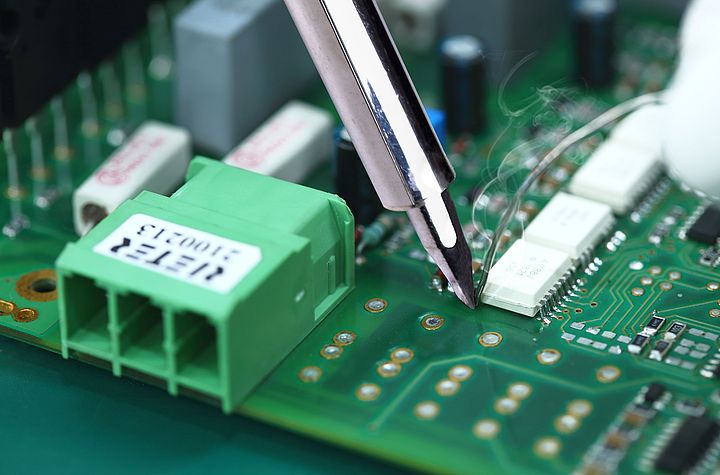

Since 1986, Rieter has been building up its repair services capability with one goal in mind: provide to its customers the highest quality repairs at the shortest turnaround time. Certified Rieter service engineers are able to perform both on-site and in-workshop repairs, using original Rieter components and spare parts. A broad range of repair products is available for all Rieter machines. Since 2022, Rieter repair services has extended its portfolio to cover all Rieter winding machines.