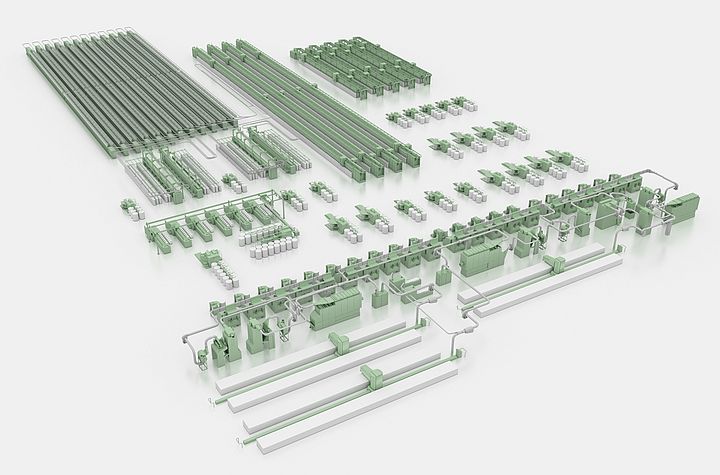

Compact-Spinning Machines and Compacting Devices

Compact-spinning machines

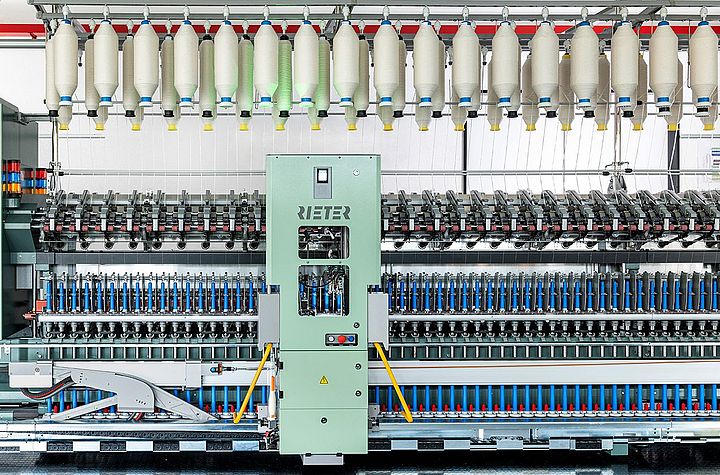

Rieter compact-spinning machines deliver premium yarns with exceptional structure and strength. By compacting fibers before spinning, they ensure maximum integration, reduced hairiness, and high tenacity. Designed for flexibility and efficiency, compact-spinning machines from Rieter are the benchmark for economical, high-quality yarn production.

Compacting devices

Rieter compacting devices transform ring-spinning machines into compact-spinning systems with ease. Simple to install and remove, Rieter compacting devices enable quick switching between yarn types. Delivering reduced hairiness and higher yarn strength, these solutions offer flexibility and performance for diverse customer requirements.

News and Success Stories

From Upgrade to Breakthrough: COMPACTapron Powers Rajaguru’s Growth

Rajaguru Spinning Mills increased productivity by 7% and significantly enhanced yarn quality by adopting Rieter’s compact spinning system COMPACTapron.

Modernizing Compact-Spinning Machines the Smart Way

How can mills deal with ageing compact-spinning machines? One smart option is converting them to conventional ring spinning machines, optionally equipped with compacting devices.

Highest Compact Yarn Quality with Indian Cotton

The Rieter compact-spinning system will enable Sportking to produce compact yarns in highest quality from Indian cotton with maximum productivity.

COMPACTeasy: Boosting Productivity by 10% at Grupo Scala Textil

Grupo Scala Textil raised productivity by 10% and improved yarn quality with Rieter’s Compact Spinning System COMPACTeasy at two of its mills.

Spinnova and Rieter publish a yarn spinning guideline for industrial partners

Spinnova and Rieter have published a comprehensive yarn spinning guideline for industrial partners, detailing how to produce compact yarn from SPINNOVA fiber using Rieter’s state-of-the-art machinery.

Guiding Arm Refurbishment: A Global Success Story

Discover how Rieter's guiding arm refurbishment enhances yarn quality, reduces energy use, and extends machine life – proven in 683 000+ upgrades worldwide.

Short-Balloon Setting Upgrade Maximizes Productivity

Masood Fabrics Limited, Pakistan, boosted the productivity of its compact spinning machines by 2.5% by installing a short-balloon setting upgrade.

Embee’s Success with the Rieter Compact-Spinning System

PT. Embee from Indonesia has again chosen a complete Rieter system – including the mill management system ESSENTIAL to optimize the spinning process.

Open House Event at Rieter Customer Embee: Showcasing Cutting-Edge Spinning Technology

Over 150 experts from spinning mills and textile manufacturers took part on guided Embee factory tour showcasing its new compact-spinning system in action.

Competitive Advantage with Automated Piecing ROBOspin

Each week in spinning mills across the globe, ROBOspin pieces more than 1 000 000 yarn breaks, resulting in a reduction of about 2 000 working hours for operators.

Ri-Q-Tubes Offer Extended Lifetime and Ensure Reliable Spinning

Rieter's Ri-Q-Tubes offer excellent dimensional stability that remains the same throughout the lifetime. Hence, customers can expect a lifetime twice as long as that of conventional tubes.

Always Faster with Onyx Travelers

Reaching full speed without compromising on quality? This is the challenge successfully mastered by Kipaş Textiles.

18% Energy Savings with Rieter Compact-Spinning Machine K 48

In a recent comparison conducted at a Turkish customer, the compact-spinning machine K 48 used 18% less energy at the same productivity than the competitor machine.

Uğurlular Places Major Order for Piecing Robot ROBOspin

Rieter has announced its latest major order for ROBOspin, the industry's first fully automated piecing robot. Uğurlular Textile Industry and Trade Inc. in Türkiye ordered more than 30 piecing robots.

ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt. Ltd. enhances its production with the use of ESSENTIALmonitor, combined with the individual spindle monitoring ISM premium on their ring and compact-spinning machines.

Ring and Compact-Spinning Performance Kit Boosts Productivity and Yarn Quality

Sreedhara Textiles has upgraded its ring spinning machines G 32 and G 36 with a ring spinning performance kit improving productivity, yarn quality and power savings.

High Level of Automation for High-Quality Compact Spinning

With Rieter compact-spinning machines K 47, directly linked to Autoconer X6, Sri Bhagirath Textiles, India produces high-quality compact yarns, economically and highly automated.

Suction Drum Refurbishment Improves Yarn Quality

Rieter repair services can refurbish the drums that show significant wear and tear, providing a reliable, long-lasting and cost-effective repair solution.