Rotor Spinning Machines

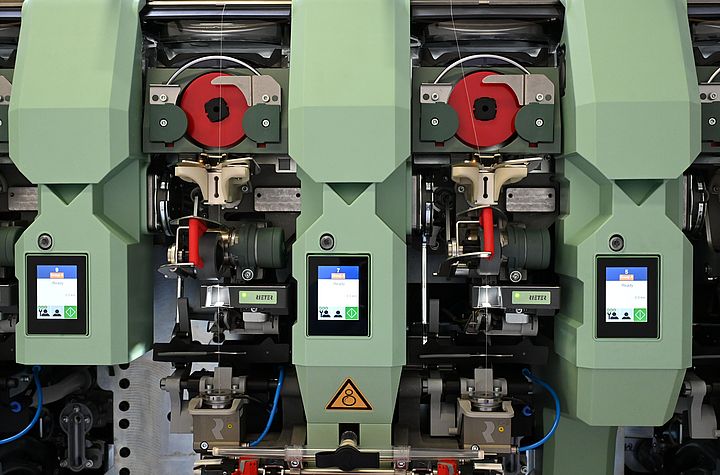

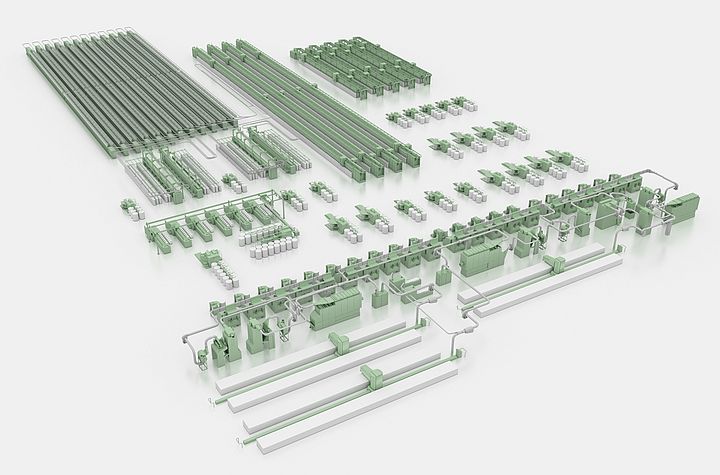

Rieter rotor-spinning machines combine highest productivity with outstanding flexibility for raw materials and yarn construction. Advanced automation features such as automatic piecing and integrated monitoring reduce downtime and personnel costs. The fully automated rotor spinning machine R 70 delivers premium Com4rotor yarns with minimal energy use, while the semi-automated R 37 ensures economical production. Independent machine sides maximize versatility for every requirement.

Products

Rotor Spinning News and Success Stories

High Efficiency and Quality for Recycled Wool with the R 37

Jiangyin Haoshun Textile boosts recycled wool production with the Rieter R 37, achieving higher efficiency, stable yarn quality, and consistent performance.

Highest Compact Yarn Quality with Indian Cotton

The Rieter compact-spinning system will enable Sportking to produce compact yarns in highest quality from Indian cotton with maximum productivity.

R 37: Production of High-Quality Yarn Made from 100% Polyester

Nuogao Fiber in China achieves high-quality 100% polyester yarns, stable consistency, and maximum efficiency with the Rieter R 37 rotor spinning system and ROBOdoff.

Nishat Mills Advances with Rieter R 37 Rotor Technology

Nishat Mills, a leading textile company in Pakistan, installed the Rieter rotor spinning machines R 37 with ROBOdoff, achieving over 99% efficiency, top yarn quality, and low energy consumption.

Spinnova and Rieter publish a yarn spinning guideline for industrial partners

Spinnova and Rieter have published a comprehensive yarn spinning guideline for industrial partners, detailing how to produce compact yarn from SPINNOVA fiber using Rieter’s state-of-the-art machinery.

High-Efficiency Rotor Spinning with R 70

American Cotton in Mexico achieves high-quality yarn production, low conversion costs and maximum efficiency with the fully automatic Rieter rotor spinning system R 70.

Yarn Clearer Q 30: Key to High-Quality Yarns and Efficient Production

The new yarn clearer Q 30 for rotor and air-jet spinning ensures top yarn quality, longer production times, and less maintenance, thanks to advanced detection technology.

Rieter Rotor Spinning System: The Sustainable Choice for Premium Recycled Yarns

Surya Spinners boosts efficiency and yarn quality in recycled yarn production using the Rieter rotor system – precise blending, lower energy use, top yarn quality.

Usha Yarns Is First Com4recycling-Rotor Licensee

By using the R 37, Usha Yarns not only meets its environmental goals but also achieves substantial gains in productivity, quality assurance, and energy efficiency.

ROBOdoff: Rotor Yarn Production with Unprecedented Efficiency

Shunyuan Textile reduced the operator load and enhanced yarn quality integrating Rieter ROBOdoff on their R 36 and R 37 rotor spinning machines.

Economical Processing of Recycled Cotton Fibers with R 37

Wenzhou Mingshuo benefits from the ability of the Rieter semi-automated rotor spinning machine R 37 to process yarn with 70% to 95% recycled cotton content.

ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt. Ltd. enhances its production with the use of ESSENTIALmonitor, combined with the individual spindle monitoring ISM premium on their ring and compact-spinning machines.

Becoming an Expert in Spinning with Rieter’s Customer Trainings

Continuous learning pays rich dividends. Rieter’s customer trainings help unlock the full potential of the mill’s technical team and maximize the benefits of the products.