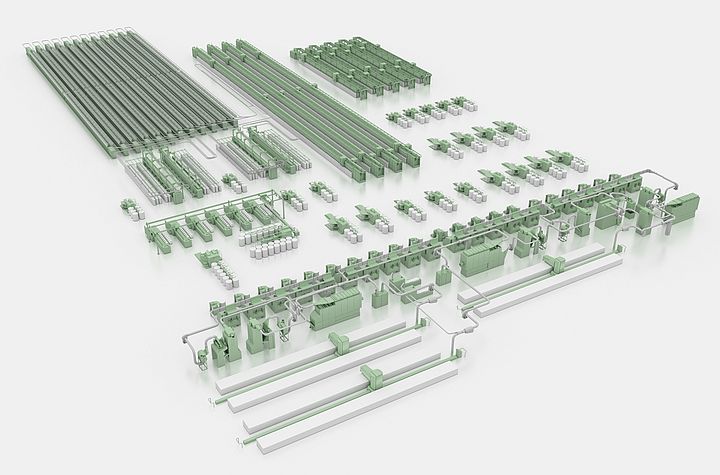

Spinning Preparation Machines

Draw Frames

Rieter draw frames ensure perfect sliver quality at the highest productivity. Advanced autoleveling technology delivers superb scanning precision and evenness, improving downstream performance. With delivery speeds up to 1,200 m/min and energy-efficient design, they set the benchmark for economical, flexible spinning preparation.

Combing Machines (Combers)

Rieter combing machines guarantee premium yarn quality and optimal raw material utilization. Together with OMEGAlap preparation, they achieve the highest combed sliver output per set on the market. State-of-the-art technology ensures consistent quality, low conversion costs, and maximum efficiency for demanding applications.

Roving Frames

Rieter roving frames deliver high-quality rovings with maximum efficiency and minimal downtime. Automated doffing systems and precise bobbin build-up reduce labor costs and boost productivity. With up to 252 positions and flexible electronic drafting options, they offer economical, reliable performance for modern spinning mills.

Spinning Preparation News and Success Stories

Burteks and Rieter – Commitment to Innovation with OMEGAlap E 40

Burteks Tekstil, Türkiye, producing with the new combing preparation OMEGAlap E 40, profits from fast lap change, low power consumption and easy maintenance.

The Most Advanced Automated Ring Spinning System in Argentina

The Rieter automated ring spinning system will support Dell Valle in manufacturing combed ring yarns of the highest quality at greatest productivity.

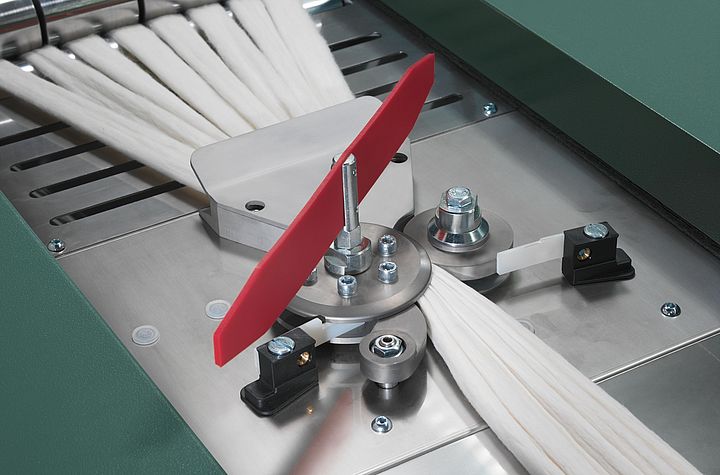

Draw Frame Mini Kit Improves Sliver and Yarn Quality

Shri Rohit Spinners implemented Rieter’s draw frame mini kit for their RSB-D 22 machine, which resulted in a significant improvement in sliver and yarn quality.

Draw Frame Pneumatic Panel Refurbishment Improves Sliver Quality

Rieter’s autoleveler draw frame pneumatic panel refurbishment enables superior machine performance and consistent sliver quality.

Rieter Ring Spinning System Powers Beste’s Fully Traceable Supply Chain

The latest Rieter technology, in conjunction with digitization and automation solutions, will support Beste in setting up the entire textile production process locally in Italy.

Vardhman Modernizes Plant with Rieter Draw Frames and Combers

Vardhman chose Rieter for modernization. They acquired 66 draw frames and 35 combers. Rieter's ROBOlap system, recycling expertise, and advanced solutions perfectly matched Vardhman's needs.

Excellent Fiber and Spinning Preparation for High Quality and Efficiency in Air-Jet Spinning

Rieter cards and draw frames are the best preparation for viscose air-jet yarn. At Baisheng Textile, they have a positive effect on the spinning efficiency as well as the quality of the yarn.

Why Rieter Draw Frames Are First Choice for Spinning Mills

Why do our customers consider Rieter draw frames the best on the market? Discover their experiences here.

Single-Head Draw Frames: Breakthrough in Flexibility at Dezhou Huayuan

Dezhou Huayuan decision to invest into Rieter single-head draw frames reflects not only in improving production efficiency but also in boosting profitability.

ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt. Ltd. enhances its production with the use of ESSENTIALmonitor, combined with the individual spindle monitoring ISM premium on their ring and compact-spinning machines.

Highest Efficiency with Automated Combing System

Fuchun Textile's spinning mill reduced labor-intensive tasks and now always operates at peak efficiency thanks to automation in the combing section.

Becoming an Expert in Spinning with Rieter’s Customer Trainings

Continuous learning pays rich dividends. Rieter’s customer trainings help unlock the full potential of the mill’s technical team and maximize the benefits of the products.

Mill Assessment Leads to Production Increase Between 44% and 70%

From blowroom to winding, Rieter identifies potential performance improvements for its customers.