Winding Machines and Yarn Processing

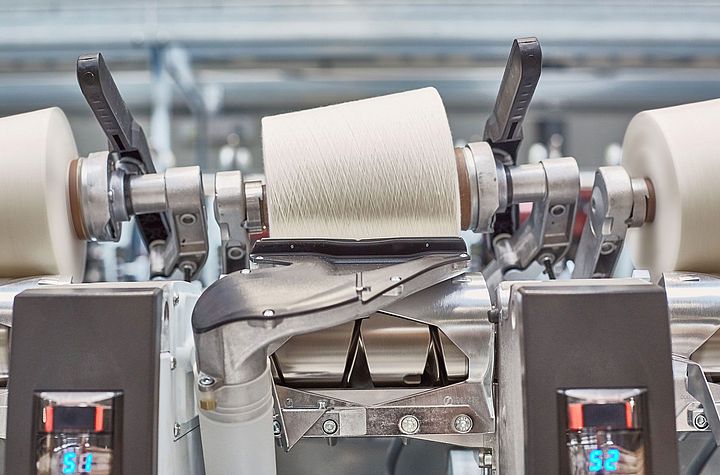

Rieter winding machines, including SSM solutions for winding and yarn processing, deliver outstanding yarn quality and perfect package build-up. Advanced processes like automated winding, splice optimization, and precision winding ensure efficiency and flexibility for staple-fiber and filament yarns across diverse applications.

Products

Winding News and Success Stories

Smart Winding Machine Upgrades for More Sustainable Yarn Production

Indo-Rama Synthetics unlocks up to 8% higher efficiency, cuts energy use and boosts yarn quality with Rieter's advanced Autoconer upgrades, driving smarter, more sustainable production.

Doubling Speed, Elevating Quality: The impact of Precision Assembly Winder NEO-BD

Hebei Jingze Textile doubles production speed using SSM’s NEO-BD precision assembly winder.

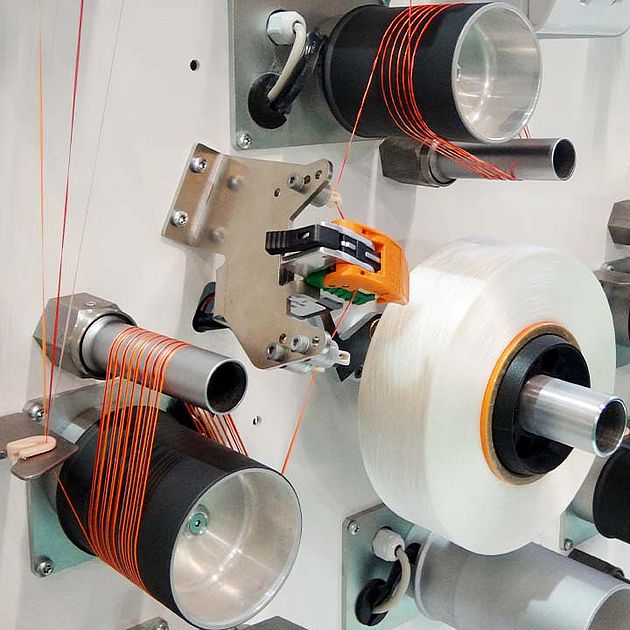

NEO-BD Precision Assembly Winder

Meet the NEO-BD: advanced textile manufacturing technology that transform yarn processing with unprecedented precision and speed.

Autoconer 338 Upgrade: More Yarn, Less Energy Use at Sanyang Textile

Suction nozzle upgrade in the Autoconer 338 increases yarn production by 3% and reduces energy use by 13% at Sanyang Textile Co., Ltd., China.

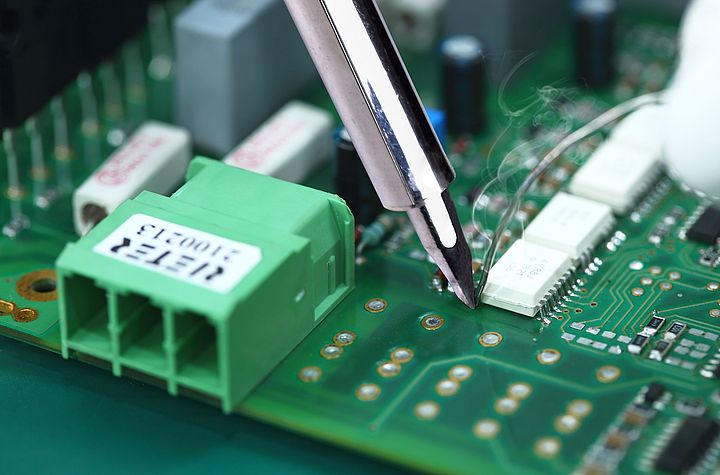

Enhanced Autoconer Performance with Winding Upgrades

Equipped with the latest features of the Autoconer X6, Rieter winding upgrades enable significant improvements in machine efficiency, energy savings and package quality.

Higher Process Efficiency with Autoconer X6 and Preci FX

The own spinning mill incl. Rieter Autoconer X6 with Preci FX winding technology enables ALC (India) to achieve cost savings, greater flexibility and increased process efficiency.

Excellence in Denim Manufacturing with Rieter Ring Spinning System

Soorty’s ring spinning mill is fully equipped with Rieter machines, covering the entire spinning process from bale to package. It enables excellence in denim manufacturing with high-quality ring yarns.

On-site Preventive Maintenance and Repair Enhances Autoconer Efficiency by 10%

Rieter’s on-site preventive maintenance and repair service for the Autoconer 338 winding machines has boosted machine efficiency by 10%, leading to increased productivity.

Vardhman: Increase of Production Capacity with Rieter Autoconer X6

Vardhman investment to Rieter winding machines Autoconer X6 increases their production output and automation level while maintaining high production standards.

Customized, Energy- and Cost-Saving Automation with Autoconer X6 Multilink

MKAS Textile Pvt. Ltd. benefits from 25% lower energy costs and higher operator independency with the new Autoconer X6 Multilink installation.

Increasing Production and Reducing Costs with Smartjet

Wugang Longshan Textile partnered with Rieter to implement the Smartjet winding upgrade for their Autoconer X5. This upgrade boosted machine efficiency by up to 3% and reduced operators' workload.

Increasing Productivity with Smartjet Winding Upgrade

The Smartjet winding upgrade increases yarn production by improving the efficiency of the upper yarn search and pick-up from the package by the suction nozzle and reducing operator workload.

Winding Expertise for Wool Applications

The Autoconer X6 with an integrated Thermosplicer uses the special thermoplastic characteristics of wool as basis for excellent splice results.

ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt. Ltd. enhances its production with the use of ESSENTIALmonitor, combined with the individual spindle monitoring ISM premium on their ring and compact-spinning machines.