Fiber Preparation Machines

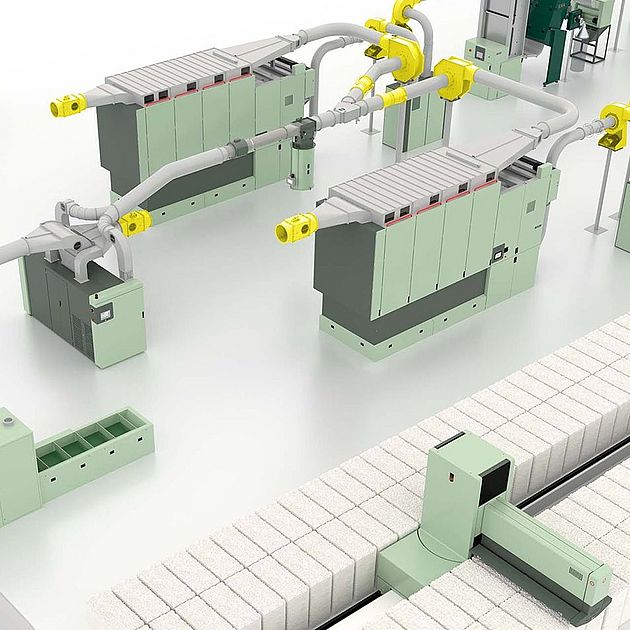

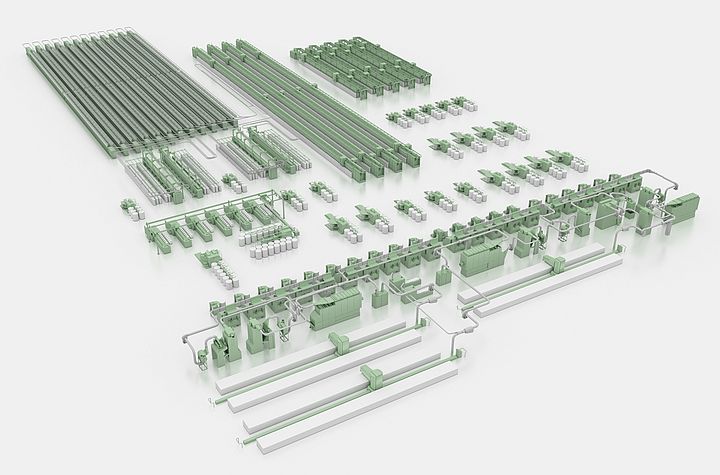

Blowroom machines

Rieter blowroom machines ensure gentle fiber opening, efficient cleaning, and precise blending for top yarn quality. The modular VARIOline concept delivers up to 2 400 kg/h production with 40% less energy use. Designed for flexibility and raw material savings, VARIOline sets the benchmark in fiber preparation.

Carding Machines (Cards)

Rieter cards combine high production with excellent sliver quality. Featuring advanced technologies like Carding Gap Control and the Integrated Grinding System, carding machines from Rieter maximize fiber yield and reduce energy consumption. With the largest active carding area, Rieter cards deliver consistent, economical performance.

Fiber Preparation News and Success Stories

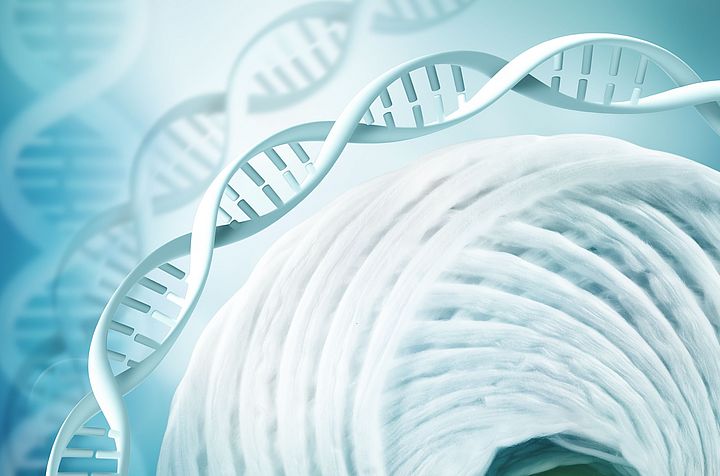

Revolutionizing Textile Supply Chains with Traceability Technology

Soorty partners with Rieter and Haelixa to transform its supply chain by integrating DNA marker technology, ensuring full traceability from fiber to finished garment.

Nipaş Revolutionizes Yarn Production with TUCAN Metallic Card Clothing

Nipaş Tekstil revolutionized its yarn production by adopting TUCAN Metallic Card Clothing, achieving maintenance-free operation, cost savings and consistently high-quality yarn. After successfully processing 1,000 tons of Ne 30 cotton without grinding, Nipaş is expanding its use of TUCAN to enhance efficiency and profitability.

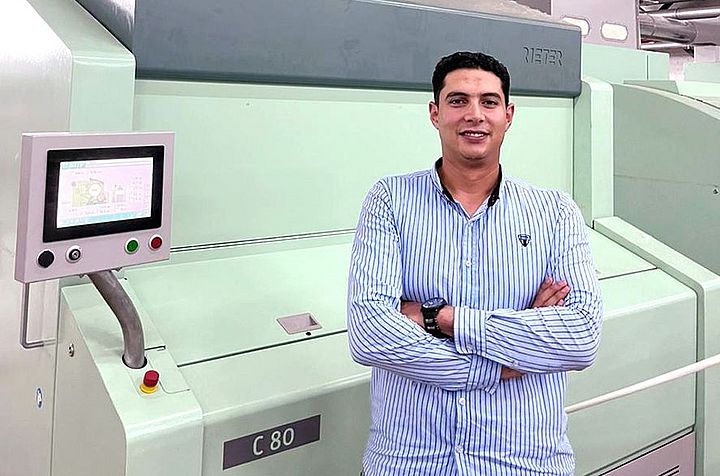

Card C 80: High-Quality Sliver Production at 120 kg/h

To further enhance production efficiency and meet quality standards, Jinshangjia recently invested in three state-of-the-art Rieter cards C 80.

GÜLLE Achieves Unparalleled Good Fiber Savings with HYPERTOP Flexible Flat

The Turkish yarn and fabric manufacturer GÜLLE has upgraded its Rieter cards with HYPERTOP C-60 flexible flats, resulting in enhanced fiber yield, while maintaining consistent imperfection values.

Excellent Fiber and Spinning Preparation for High Quality and Efficiency in Air-Jet Spinning

Rieter cards and draw frames are the best preparation for viscose air-jet yarn. At Baisheng Textile, they have a positive effect on the spinning efficiency as well as the quality of the yarn.

Card C 81: Processing 100% Noil or Card Waste at 160 kg/h

Qianjiang Changyun Textile’s recent investment in a Rieter fiber preparation line, featuring the high-performance card C 81, has greatly improved its processes and reduced energy consumption.

Surya Spinners Doubles Production with UNIblend A 81

The UNIblend A 81 ensures high production, flexibility, and precision for Surya Spinners and its various blend ratios for the production of rotor yarn.

Card C 80: A Game-Changer in Fiber Preparation

At MEM Textile from Türkiye, the C 80 card forms the basis for high-quality yarns with a remarkable production speed and outstanding sliver properties.

Reconditioning Carding Flats Increases Lifetime and Productivity

The FlatCLIP implemented in cast iron flats offers a cost-effective and sustainable solution to increase the lifetime and productivity of the cards.

Unmatched Fiber Preparation with Card C 80

The card C 80 forms the basis for high-quality yarns with a remarkable production and excellent sliver properties at Burteks Tekstil from Türkiye.

ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt. Ltd. enhances its production with the use of ESSENTIALmonitor, combined with the individual spindle monitoring ISM premium on their ring and compact-spinning machines.

Skytex Spinning Boosts Productivity with Card C 80

Skytex Spinning increased productivity with the high-performance card C 80. In addition, the implementation of the C 80 marks a significant leap for the company in terms of energy efficiency.

Cutting Energy by 57%: Sapphire's VARIOline ECOrized Success

Sapphire Textile Mills invested in the Rieter blowroom line VARIOline ECOrized to reduce energy costs in producing high-quality ring spinning yarn.

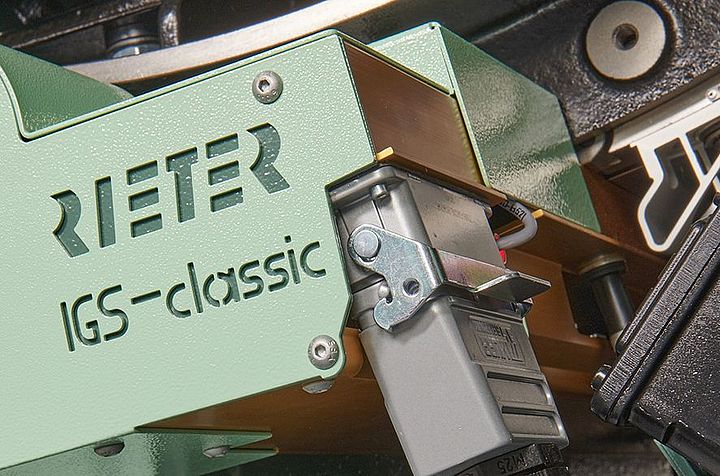

IGS-classic – A Unique Solution for Consistent Quality

Exclusively available for Rieter cards, IGS-classic satisfies customer requirements, including an increase in the cylinder wire lifetime of up to 20%.

Carding Solutions for a Sustainable Yarn Production

Rieter's recycling solution for cards helps Surya Spinners increase production and quality while reducing energy consumption, further enhancing their eco-friendly production process.