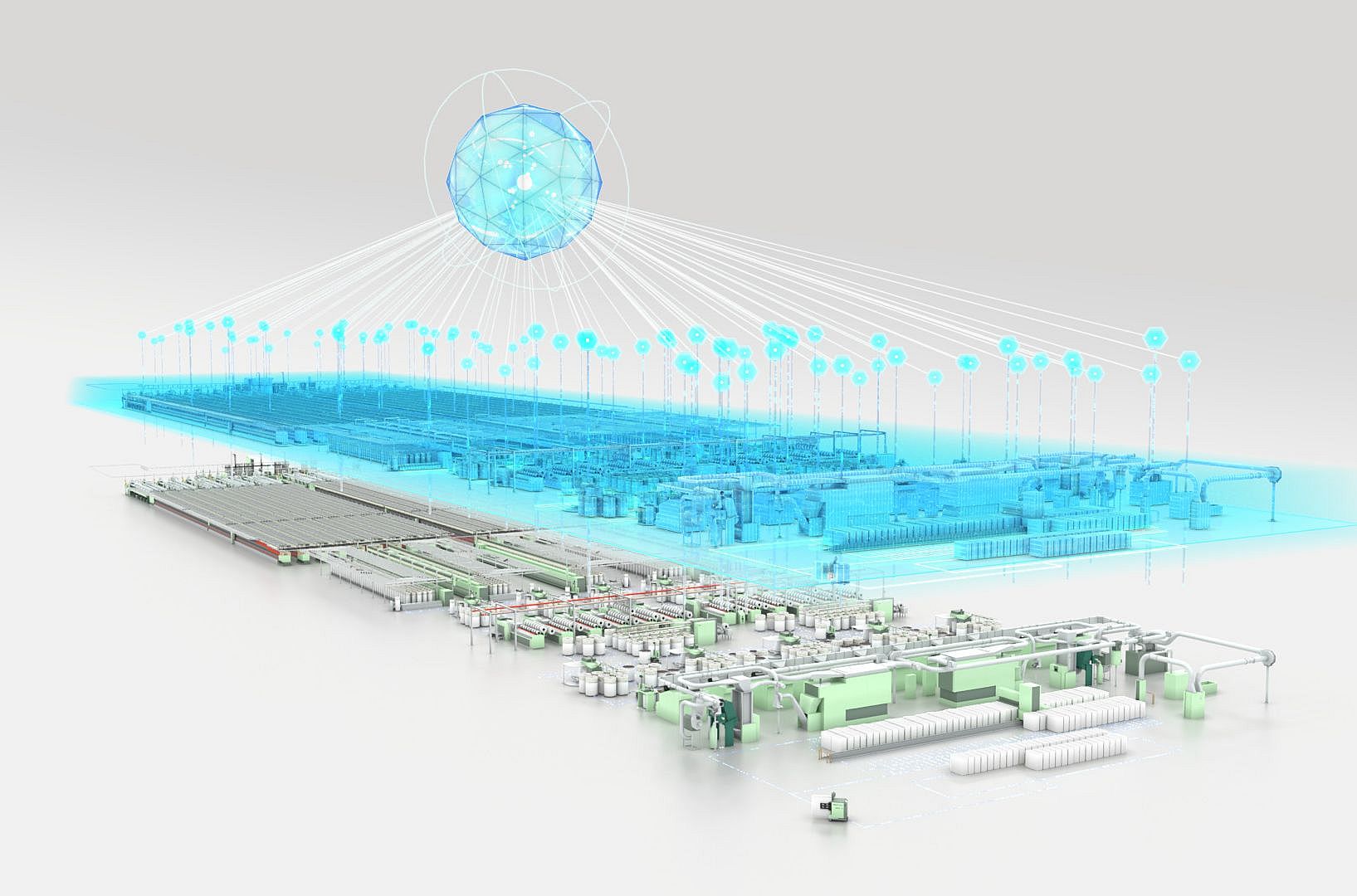

Smart Spinning Mill

Imagine the potential of a spinning mill where digital intelligence connects every step and autonomous robots take over manual work. Welcome to the spinning mill of the future — the vision Rieter is consistently shaping.

Benefits

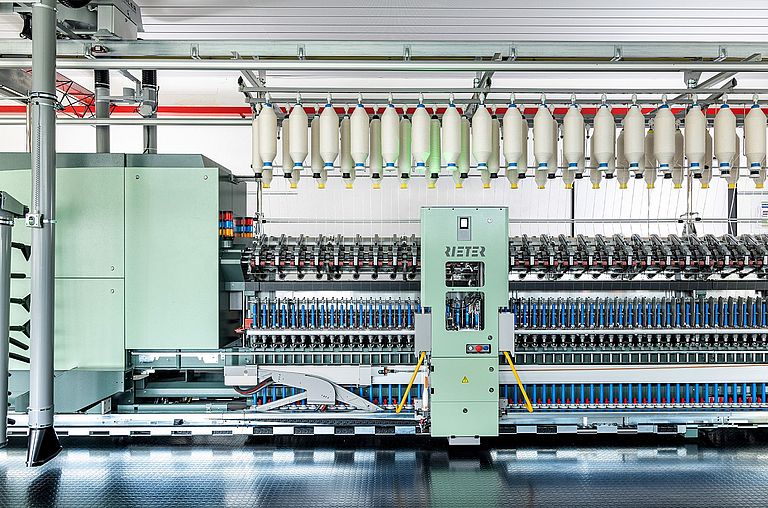

Reduced labor requirements

Smart automation and autonomous robots take over routine and physically demanding tasks, significantly lowering the need for manual intervention. This allows the workforce to focus on higher-value activities, improving both efficiency and job quality.

Improved profitability

By optimizing processes and reducing downtime, the smart spinning mill lowers operating costs and increases output. Higher efficiency, consistent quality, and reduced waste directly translate into stronger profitability.

Full transparency across the spinning process

Integrated digital platforms connect every step from fiber intake to finished yarn, making all data visible in real time. This transparency enables faster decisions, predictive maintenance, and continuous optimization throughout the mill.

Automation and Digitization

Achieving full autonomy requires more than optimizing individual machines. It calls for a holistic approach that spans the entire spinning process – from fiber to final package – with seamless information flow across all stages.

At the heart of this transformation are two key pillars: digitalization and automation. These domains must converge to create a fully integrated system where machinery, software, robotics, and data flows operate in perfect harmony.

Rieter already offers solutions that bring these pillars to life today. By investing in digitalization and automation, mills can secure future readiness while gaining immediate benefits. Explore how our technologies lay the foundation for the smart spinning mill.

Ready to modernize your spinning processes?

Contact our team to learn how we can support your goals in efficiency, quality, and workforce optimization.