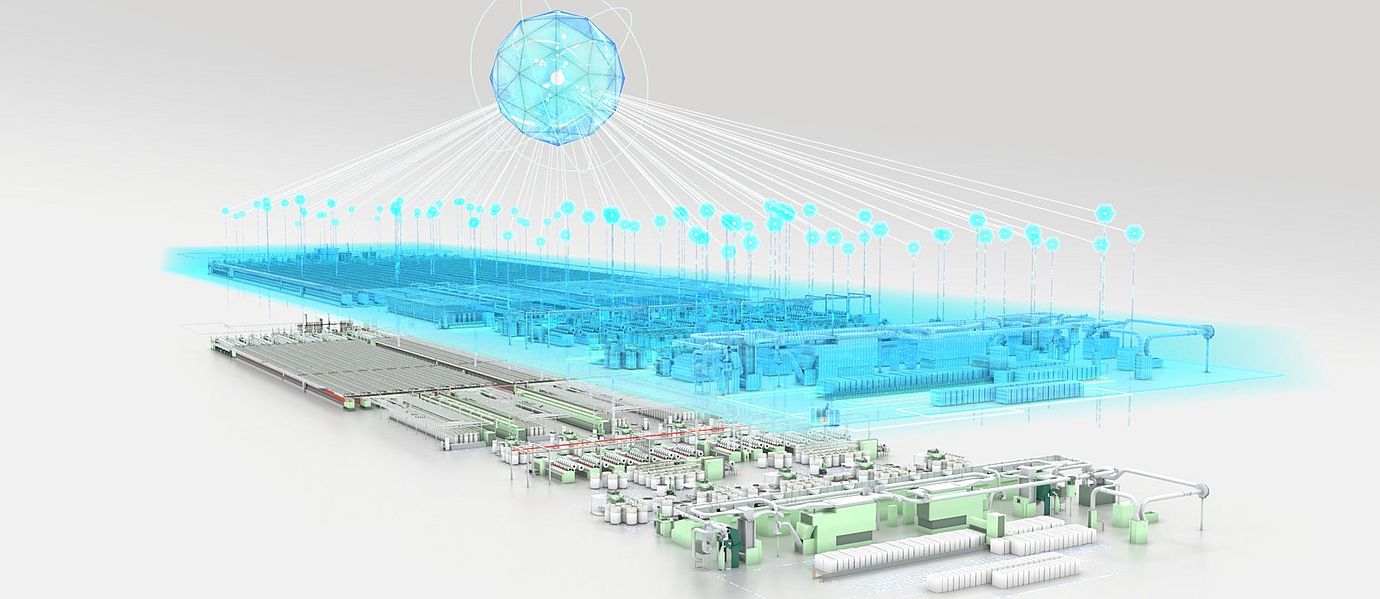

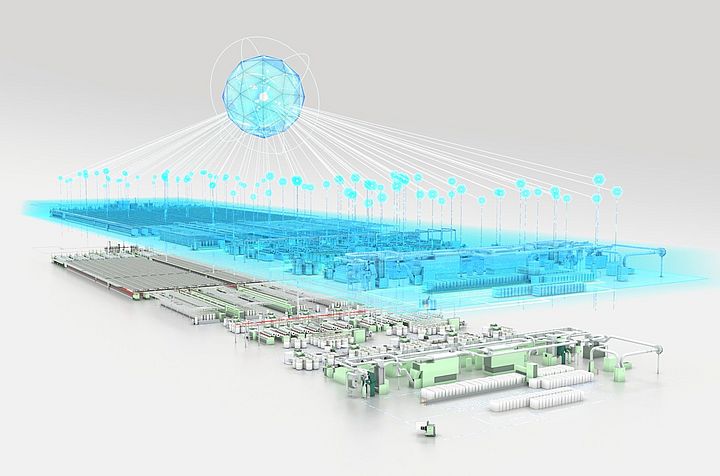

Spinning Mill Digitization

In the information age, data is the new gold — and spinning mills can unlock its value through digitization. Turning processes into data creates insights that pave the way for smarter, future-ready operations. Investing in digitization today means securing competitiveness for tomorrow.

Digitization benefits

Transparency across the entire production process

From fiber to finished yarn, digitization ensures full visibility of every step. This transparency strengthens process control, enables continuous optimization, and lays the foundation for smarter, more connected spinning mills.

Real-time monitoring of quality and energy

Digital platforms provide real-time insights into product quality and energy consumption across the spinning process. Faster, data-driven decisions boost efficiency and directly increase profitability.

Optimized maintenance and smarter spare parts management

Digitization enables predictive maintenance by detecting wear and disruptions early, reducing downtime and costs. At the same time, digital platforms simplify spare parts procurement — making ordering via webshop faster and more efficient.

Digitization solutions

With the Digital Spinning Suite Essential and the Rieter Webshop, Rieter offers digital solutions for the entire spinning process.

Digitization News and Success Stories

Smarter, Faster, and Simpler Parts Ordering

Rieter’s new webshop empowers customers with smart sourcing of spare parts for anything from blowroom to winding machines, upgrades and conversions.

Redefining the Spinning Mill

In 2027, three operators with 10 000 spindles will produce 1.9 tons of yarn per shift.

The Smart Path Into the Digital Future

How ESSENTIAL increases transparency and efficiency in spinning mills.

Embee’s Success with the Rieter Compact-Spinning System

PT. Embee from Indonesia has again chosen a complete Rieter system – including the mill management system ESSENTIAL to optimize the spinning process.

Frequently asked questions

Why is Rieter the right partner for spinning mill digitization?

Rieter combines deep textile expertise with a holistic digital approach, covering the entire spinning process from fiber to yarn. With seamlessly integrated machines, software, and automation, Rieter ensures reliable performance and investment security. Current solutions already pave the way toward the Smart Spinning Mill, giving managers future-ready operations and a trusted partner with decades of industry experience.

What role does digitization play in spinning mill automation?

Digitization is the key enabler of advanced automation in modern spinning mills. It allows machines to collect and exchange data in real time – enabling intelligent process control, predictive maintenance, and optimized material flow. Rieter's digital platform, ESSENTIAL, consolidates this data across the entire production chain, forming the foundation for end-to-end automation.

By combining digital insights with automated machinery, spinning mills can significantly reduce downtime, minimize manual intervention, and ensure consistently high production quality. Looking ahead, digitization will make it possible to integrate autonomous robots into daily operations – opening the door to the fully connected, smart spinning mill of the future.

Ready to modernize your spinning processes?

Contact our team to learn how we can support your goals in efficiency, quality, and workforce optimization.