Spinning Mill Automation

Modern spinning mills face increasing demands – from skilled labor shortages to pressure for higher efficiency and lower costs. Automation provides a powerful response: it reduces labor costs, ensures consistently high yarn quality, and increases equipment utilization.

Automation benefits

Workforce optimization

Spinning mills around the world are finding it increasingly difficult to recruit personnel willing to work on the shop floor – especially for physically demanding or repetitive tasks.

Automation offers a solution by taking over these routine operations, allowing employees to focus on more meaningful, skilled, and value-adding work. This not only improves job satisfaction but also helps spinning mills stay productive despite ongoing labor shortages and high staff turnover.

Consistently high yarn quality

Automated production ensures consistent yarn quality by eliminating variations caused by manual intervention. Real-time monitoring of process and quality parameters guarantees that high standards are maintained continuously – a key competitive edge in the textile industry.

Greater efficiency and profitability

Automation boosts production output and optimizes resource usage, for example through improved material utilization and reduced energy consumption.

This translates into significantly higher cost-effectiveness and strengthens the long-term competitiveness of the spinning mill.

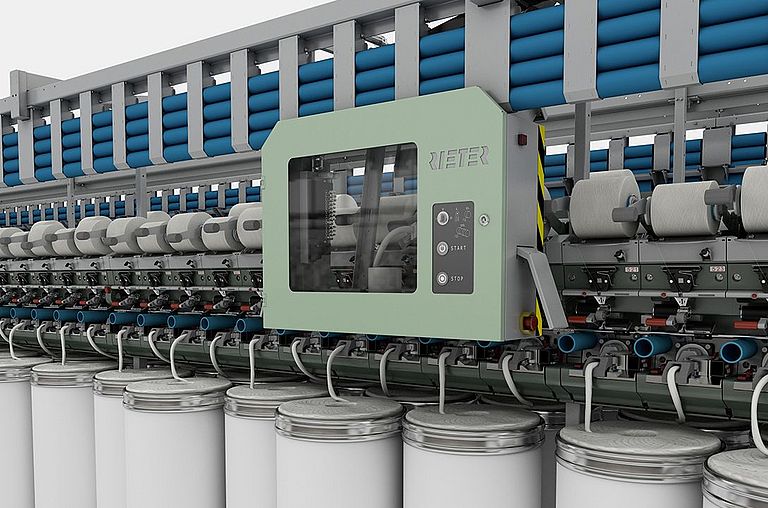

Automation solutions

All spinning methods can already be fully automated. Find out which automation solutions best suit your specific process.

Automation News and Success Stories

R 37: Production of High-Quality Yarn Made from 100% Polyester

Nuogao Fiber in China achieves high-quality 100% polyester yarns, stable consistency, and maximum efficiency with the Rieter R 37 rotor spinning system and ROBOdoff.

High-Efficiency Rotor Spinning with R 70

American Cotton in Mexico achieves high-quality yarn production, low conversion costs and maximum efficiency with the fully automatic Rieter rotor spinning system R 70.

Customized, Energy- and Cost-Saving Automation with Autoconer X6 Multilink

MKAS Textile Pvt. Ltd. benefits from 25% lower energy costs and higher operator independency with the new Autoconer X6 Multilink installation.

Competitive Advantage with Automated Piecing ROBOspin

Each week in spinning mills across the globe, ROBOspin pieces more than 1 000 000 yarn breaks, resulting in a reduction of about 2 000 working hours for operators.

Frequently asked questions

Why is Rieter the right partner for spinning mill automation?

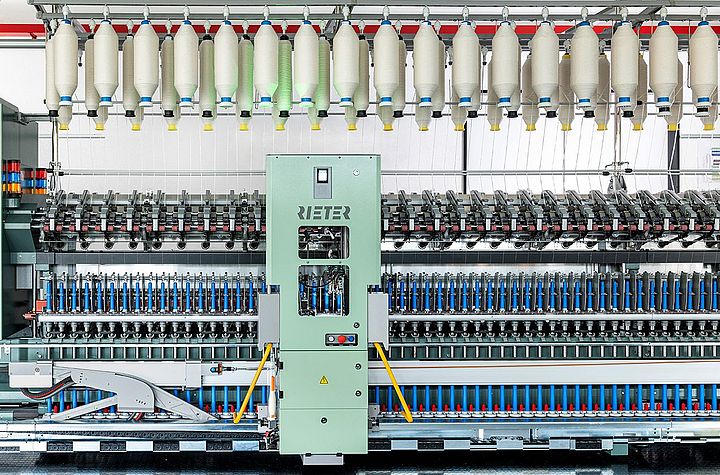

Rieter combines over 230 years of experience in textile machinery with a clear focus on future-oriented automation solutions. The company not only develops high-performance machines, but also offers integrated systems that cover the entire spinning process – from fiber preparation to yarn packaging. With innovations like the piecing robot ROBOspin and the ESSENTIAL Digital Spinning Management System Rieter enables spinning mills to optimize labor, improve yarn quality, and increase efficiency.

In addition, Rieter works closely with a global network of innovation partners and research institutions to drive developments in robotics, digitization, and system integration. This makes Rieter a reliable, forward-thinking partner for mills seeking to implement or expand automation.

What role does digitization play in spinning mill automation?

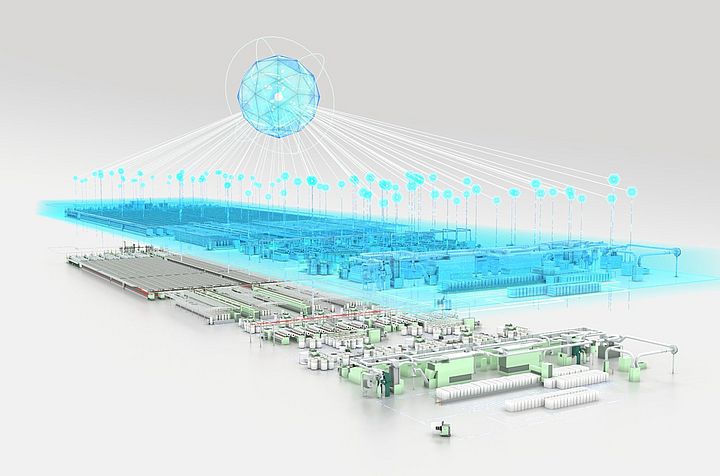

Digitization is the key enabler of advanced automation in modern spinning mills. It allows machines to collect and exchange data in real time – enabling intelligent process control, predictive maintenance, and optimized material flow. Rieter's digital platform, ESSENTIAL, consolidates this data across the entire production chain, forming the foundation for end-to-end automation.

By combining digital insights with automated machinery, spinning mills can significantly reduce downtime, minimize manual intervention, and ensure consistently high production quality. Looking ahead, digitization will make it possible to integrate autonomous robots into daily operations – opening the door to the fully connected, smart spinning mill of the future.

Which processes in spinning mills can be automated today?

Today, most steps in the spinning process – from bale opening to winding – can be highly automated. Fiber preparation, sliver transport, and spinning itself are largely autonomous in modern mills. However, areas like material handling and piecing-in at ring spinning machines still offer untapped potential. Rieter’s solutions, such as the piecing robot ROBOspin, address exactly these remaining manual tasks, pushing automation further than ever before.

How can I start automating my spinning mill with Rieter?

Rieter offers tailored automation solutions based on your specific process setup and production goals. Whether you’re looking to automate individual steps or plan a complete transformation, Rieter provides consulting, system integration, and advanced digital tools to support you at every stage. Get in touch with our experts to explore your options and plan the next steps toward a more efficient, automated spinning operation.

Ready to modernize your spinning processes?

Contact our team to learn how we can support your goals in efficiency, quality, and workforce optimization.