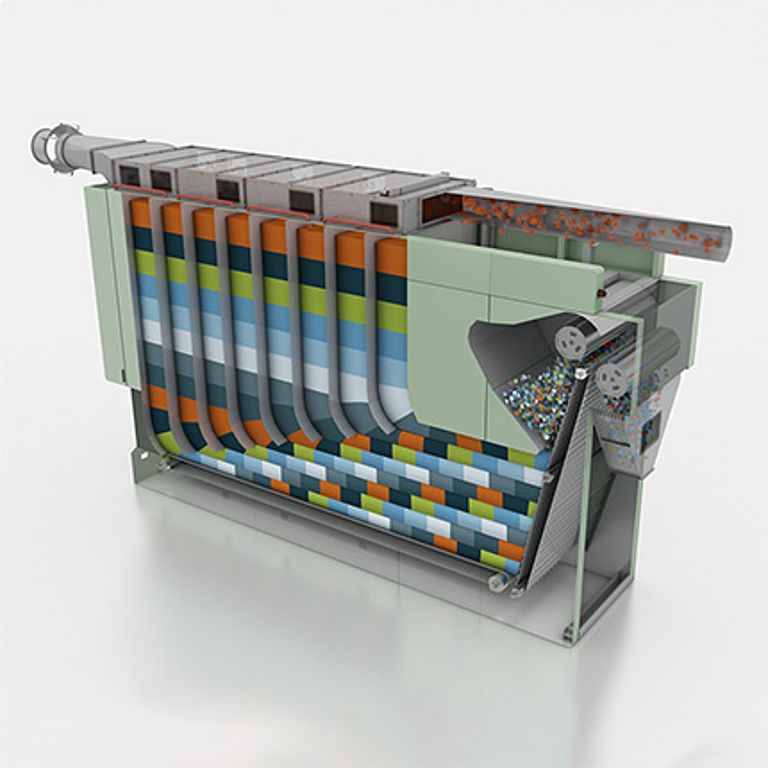

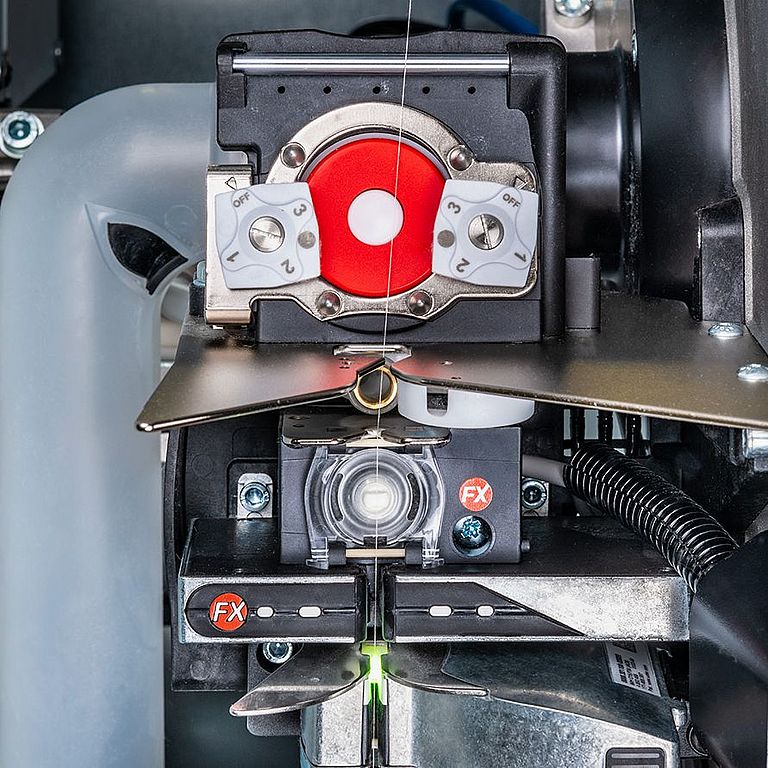

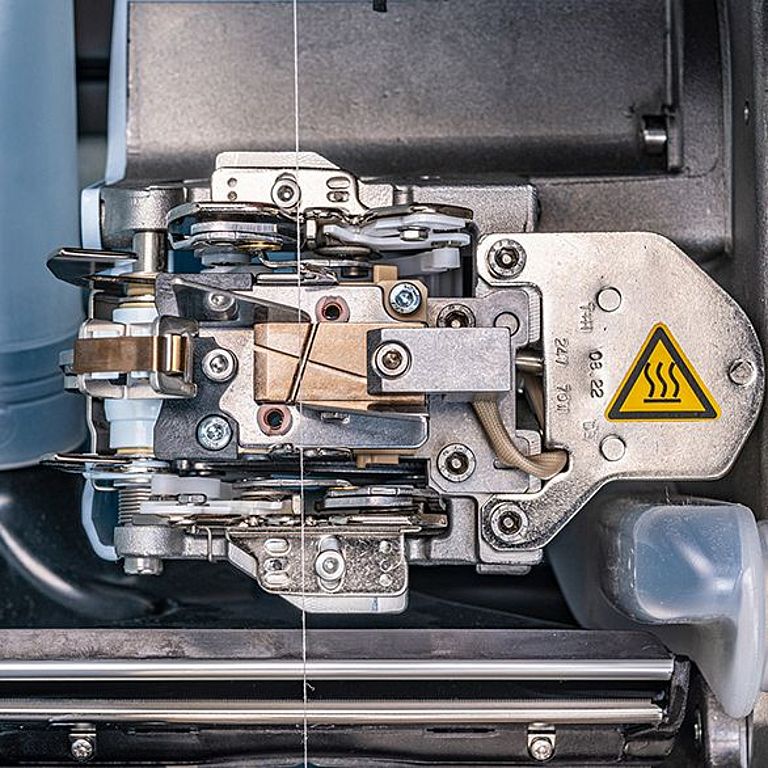

Man-made fibers are on the rise. Blends with different fiber materials are particularly popular. When processing man-made fibers and blends, short-staple spinning mills face different challenges than with natural fibers. The most important challenges are the fiber finish, imperfect material in the form of fiber packages, the electrostatic charge, and the risk of heat-induced damage.

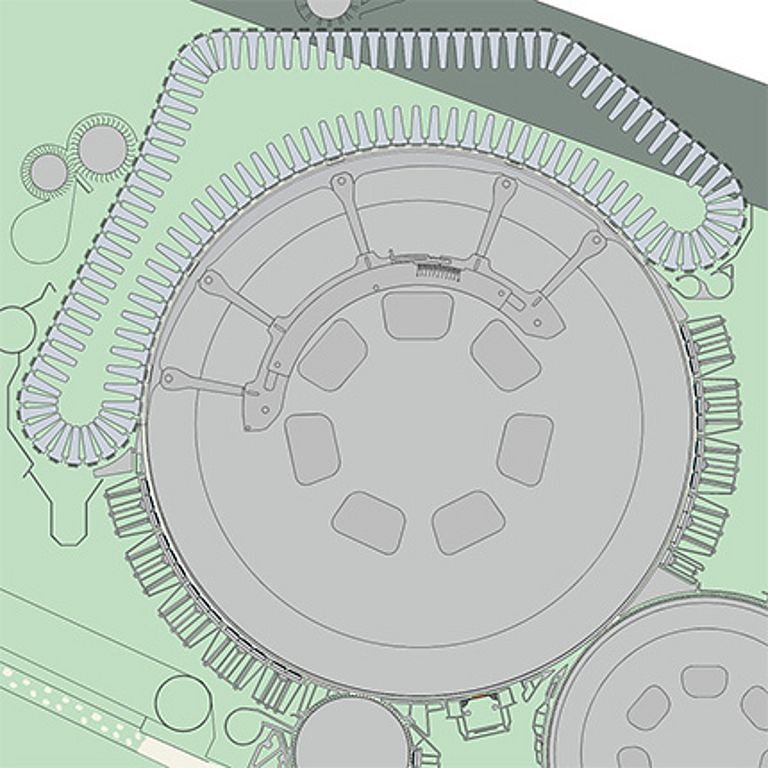

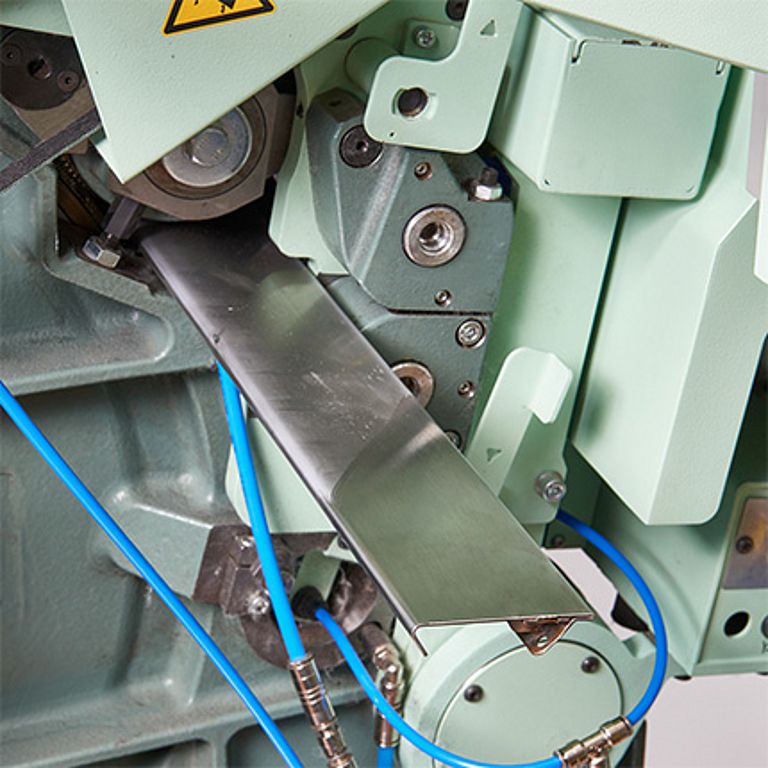

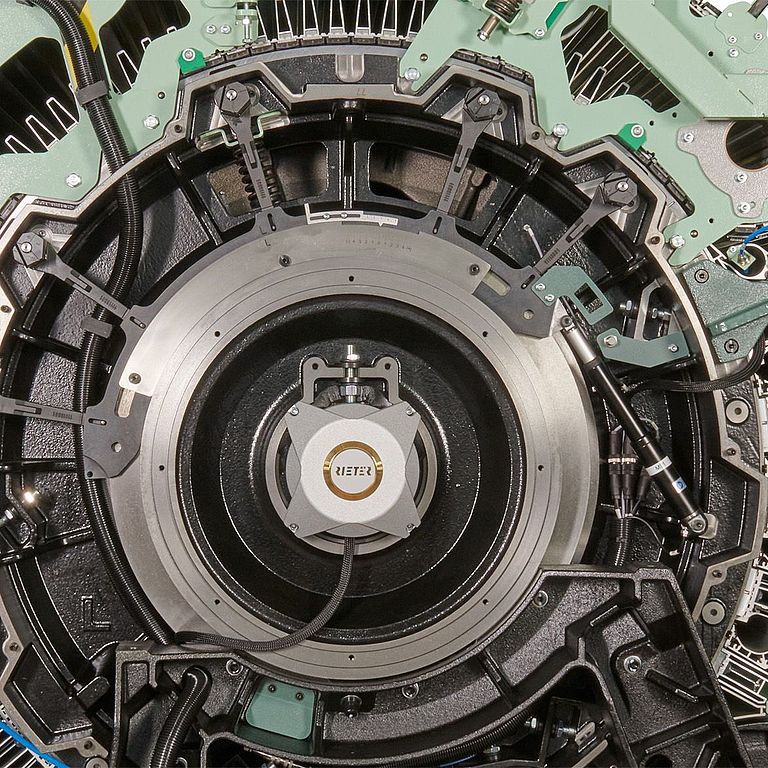

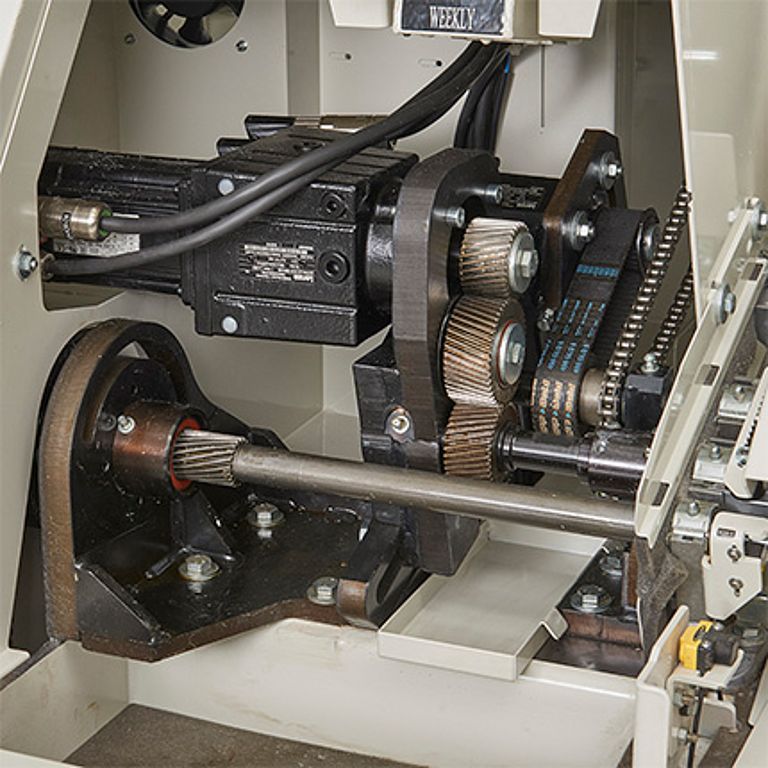

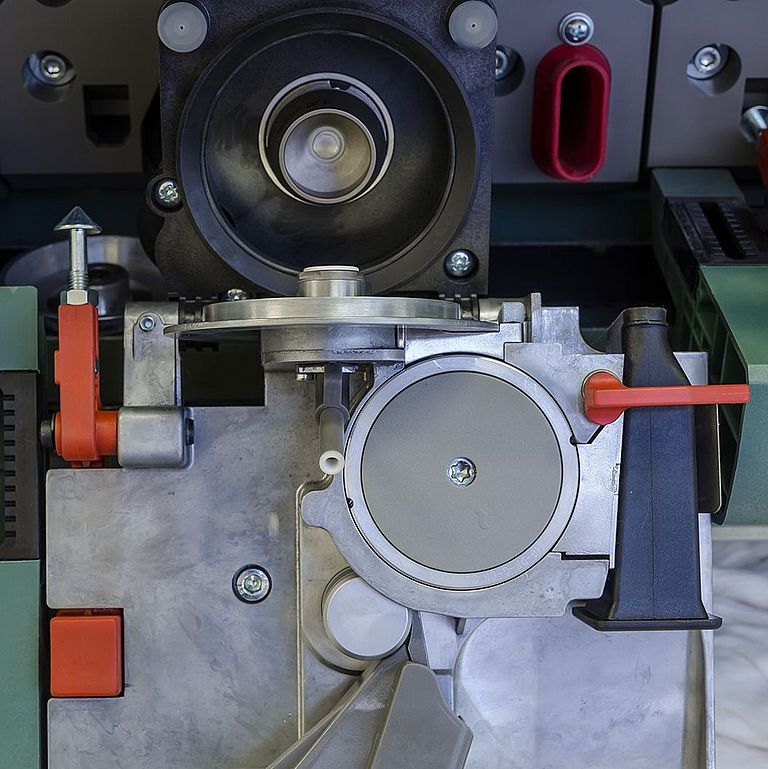

Rieter machines offer unique solutions for processing man-made fibers and blends from the blowroom to end-spinning and have been used in this field already for many years. In addition to addressing these challenges, Rieter systems stand out for their flexibility in adapting to a wide range of fiber types and blend ratios, enabling mills to respond quickly to market demands. The low conversion costs achieved through optimized machine efficiency and energy-saving technologies contribute to higher profitability.

Furthermore, Rieter’s advanced spinning solutions ensure excellent yarn quality, even when working with demanding synthetic materials and blends, supporting consistent downstream performance.