Product details

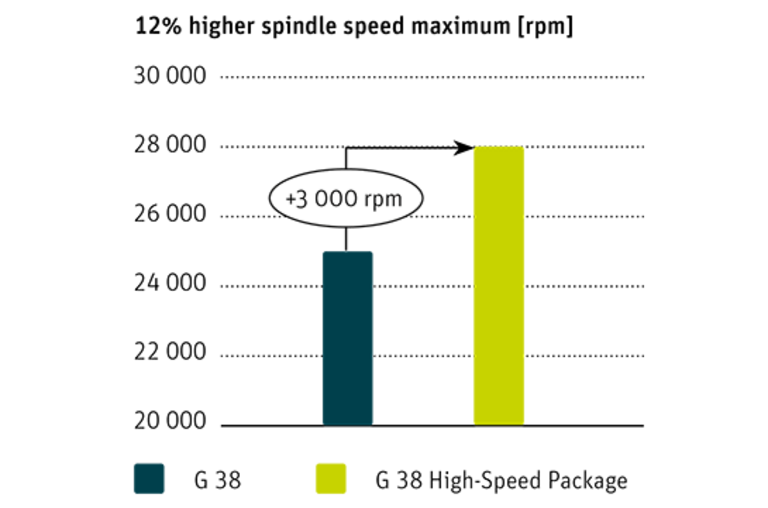

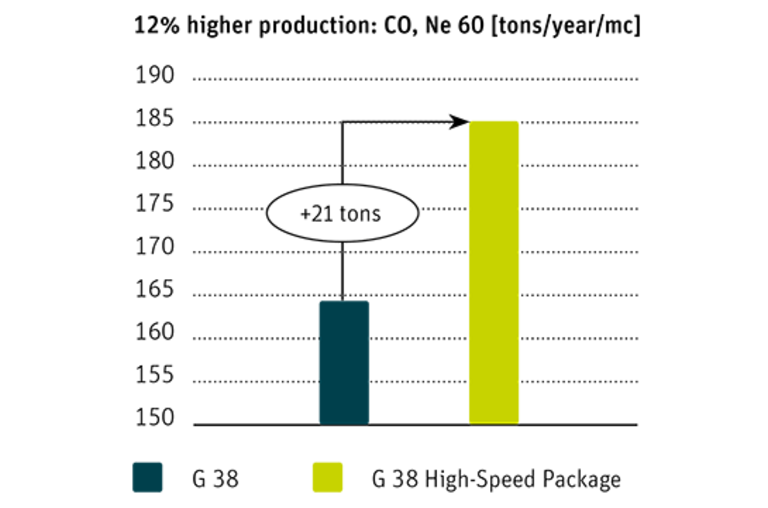

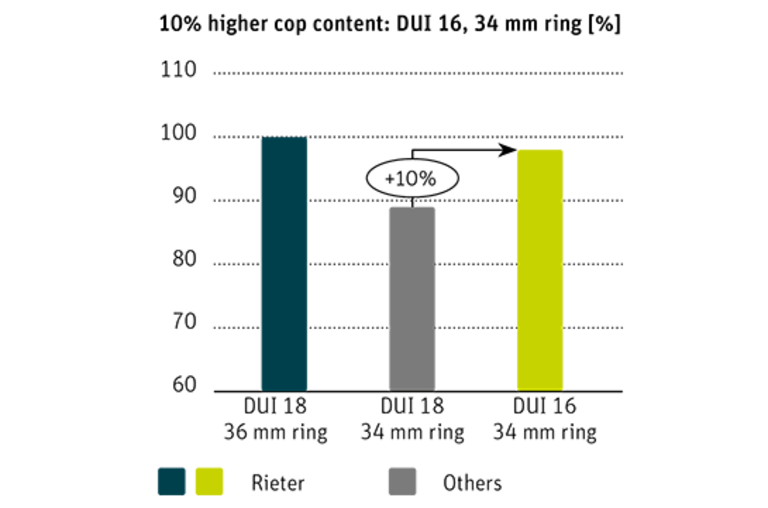

The further development of the proven Rieter ring and compact-spinning machines with the High-Speed Package yields enormous benefits to the customer in terms of productivity, flexibility, and energy savings. Maximum spindle speeds are achieved based on optimized spindles, tubes, and spinning rings. With a delivery speed of up to 40 m/min, the ring spinning machine with High-Speed Package produces up to 12% more yarn. Selecting the right components is crucial for higher productivity with consistently good yarn quality.