Carding Solutions for a Sustainable Yarn Production

Surya Spinners, a leading recycled yarn manufacturer in South India, produces a range of recycled rotor yarn from pre-consumer material using Rieter cards and rotor spinning machines. Their commitment to sustainability is key to their success. Rieter's recycling solution for cards helps them increase production and quality while reducing energy consumption, further enhancing their eco-friendly production process.

The Challenge

Global market demand for recycled yarn is increasing and Surya Spinners' response is to offer an exceptional range of sustainable yarns in various yarn counts. To meet this increasing demand and continue its rapid growth, the company is now looking to expand its production capacity. In addition to increasing productivity and quality, Surya Spinners is committed to minimizing its energy consumption and promoting an even more sustainable yarn manufacturing process. The company turned to Rieter to retrofit two of its existing cards C 70 for recycling applications while maximizing productivity and ensuring high-quality production.

The Solution

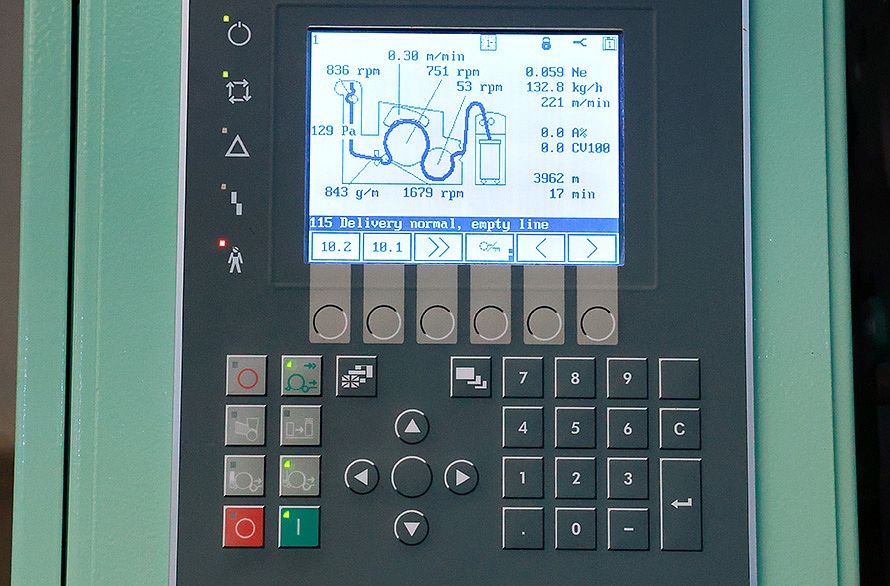

Rieter met the company's challenge and retrofitted its cards C 70 with new settings and wires to run smoothly with recycled material. The team optimized the cards and consequently increased productivity by almost twice compared to the existing 1-meter card of a competitor. At this high production rate, the cards achieved even better yarn quality while reducing energy consumption by 27%. The consistently high productivity was achieved through the combination of 1.5 m working width, 32 active flats and the Integrated Grinding System (IGS). Surya Spinners was also recommended to invest in cards C 72 with single licker-in, which deliver further advantages over the C 70 at a high production of 150 kg/h.

The Customer’s Benefits

Thiyagarajan Kuppusamy, the director of Surya Spinner, could observe numerous benefits from the upgrade. Compared to the competitor card, the upgraded cards C 70 have an 88% higher productivity and consume 27% less energy. This leads to improved efficiency of their semi-automated rotor spinning machines R 37. In addition, yarn imperfections were reduced by 23%. In absolute numbers, the overall energy savings will amount to INR 2 million per year.

Thiyagarajan Kuppusamy expressed his delight with Rieter's exceptional performance. He praised the consistent sliver quality achieved across all types of recycled materials, which has been a game-changer for their business. He also commended Rieter for helping them achieve their mission of producing high-quality recycled yarns in a sustainable manner. The results exceeded their expectations, and they are excited about the future possibilities that this partnership holds.

After experiencing the substantial benefits of the retrofitted cards C 70, Surya Spinners decided to add three cards C 72 to their existing machinery. The optimized waste air suction system of the C 72 will further reduce the energy consumption while enhancing overall performance.

The consistent sliver quality has been a game-changer for us, and the significant reduction in energy consumption contributes greatly to our sustainable production practices. We are excited about the future possibilities that this partnership holds.Thiyagarajan Kuppusamy, Director of Surya Spinner

Download

About Surya Spinners

Surya Spinners, a manufacturing company established in 2010, has become one of the prominent manufacturers of sustainable recycled yarn that is used in the production of knitted and woven garments. Their product range includes recycled rotor yarn in a range of yarn counts, from Ne 6 to Ne 40, which is made using pre-consumer material. This pre-consumer material is pre-opened for spinning in their own tearing unit. In 2021, Surya Spinners achieved an annual yarn production of 3 000 tons from their two spinning mills, both of which are in Vellakovil, South India. Their commitment to sustainability has been the driving force behind their success, with a focus on producing eco-friendly products that benefit both the planet and the business.