Skytex Spinning Boosts Productivity with Card C 80

Raed Sarmini, CEO at Skytex Spinning

Skytex Spinning, one of the pioneering manufacturers of ring yarn in Egypt, increased productivity with the high-performance card C 80. The modular design of the card further optimized operations, resulted in cost savings, and makes Skytex an industry pioneer ready for future growth. In addition, the implementation of the C 80 marks a significant leap for the company in terms of energy efficiency.

The Challenge

Skytex Spinning needed to boost its production capacity and efficiency to meet the ever-increasing demands of the market. With the existing cards C 70, the spinning mill was producing 85 kg/h of sliver. Although the C 70 was a reliable workhorse, Skytex Spinning needed to explore new possibilities to stay ahead in the competitive textile industry. Additionally, the company faced the challenge of processing cotton contaminated with insect honeydew, which required extra effort and resources.

The Solution

Skytex Spinning decided to partner with Rieter once again to find a suitable solution. Rieter introduced them to the card C 80, a machine known for its high productivity, advanced features and modular construction, which can also efficiently process honeydew-contaminated cotton. The C 80 promised to take productivity to new heights, while enhancing sliver and yarn quality as well as reducing energy consumption.

The Customer's Benefits

At Skytex Spinning the card C 80 is producing high-quality sliver with 120 kg per hour which is an increase in production of 40%. Furthermore, the C 80's modular design proved invaluable in handling honeydew-contaminated cotton effectively. Essentially, the C 80 streamlines the cleaning process with its modular design, guaranteeing easy access to all key machine components. As an illustration, the web bridge of the C 80 can be easily removed and cleaned of any honeydew residues that may have built up. Skytex Spinning can now process such fibers with ease, ensuring minimal disruptions and maximizing production efficiency. This capability positioned them favorably in the market, as they could cater to diverse customer needs without compromising on quality.

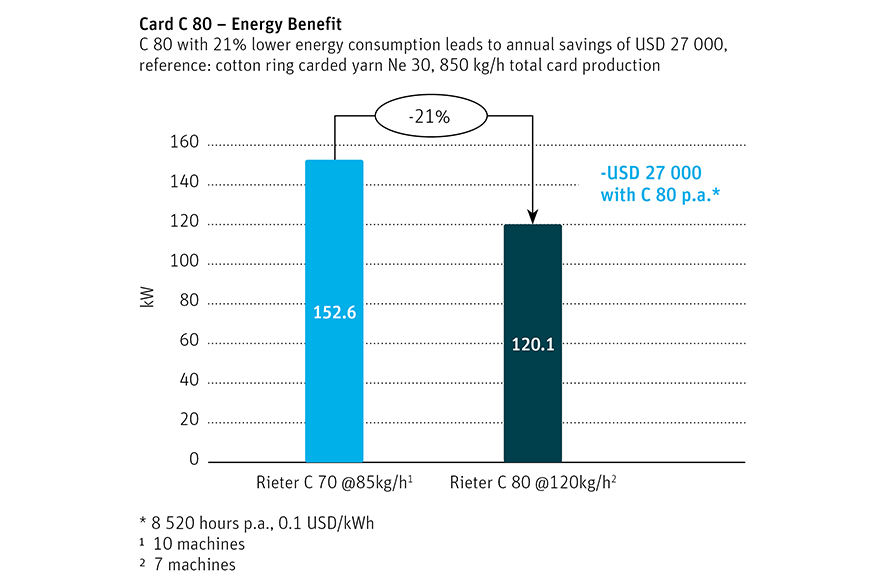

In addition, the introduction of the card C 80 brings Skytex Spinning a remarkable advance in energy efficiency. Ten cards C 70 are currently required for a yarn production of 850 kg/h. With the C 80, however, the same yarn performance could now be achieved with only seven machines. This transition could result in a significant reduction in energy consumption of 21%. This lower energy consumption is not only ecologically, but also financially beneficial – annual savings of approximately USD 27 000 would be possible.

Our partnership with Rieter and the high-performance card C 80 have revolutionized our yarn production – both in terms of quality and productivity. We have significantly enhanced our cotton processing, which gives us a clear competitive advantage.Raed Sarmini, CEO at Skytex Spinning

Download

About Skytex Spinning

Skytex Spinning, situated in 10th of Ramadan, Egypt, is recognized in the textile industry for its dedication to quality. Specializing in the production of premium yarn, Skytex Spinning offers yarns, ranging from Ne 20 to Ne 30, catering to diverse customer needs across various applications. Currently, Skytex Spinning produces 18 tons of yarn per day, consisting of 100% carded cotton yarn and core spun yarn. As part of their commitment to growth and advancement, they have ambitious plans to increase their daily production capacity to 25 tons in the future. With decades of experience and a strong foundation built on traditional methods, Skytex Spinning has consistently adapted to emerging technologies to remain at the forefront of the market.

Skytex Spinning

10th of Ramadan

Egypt