Short-Balloon Setting Upgrade Maximizes Productivity

Malik Asad Ullah, Technical Director of Masood Fabrics Limited (Spinning Unit), appreciates Rieter’s expertise in optimizing machine performance.

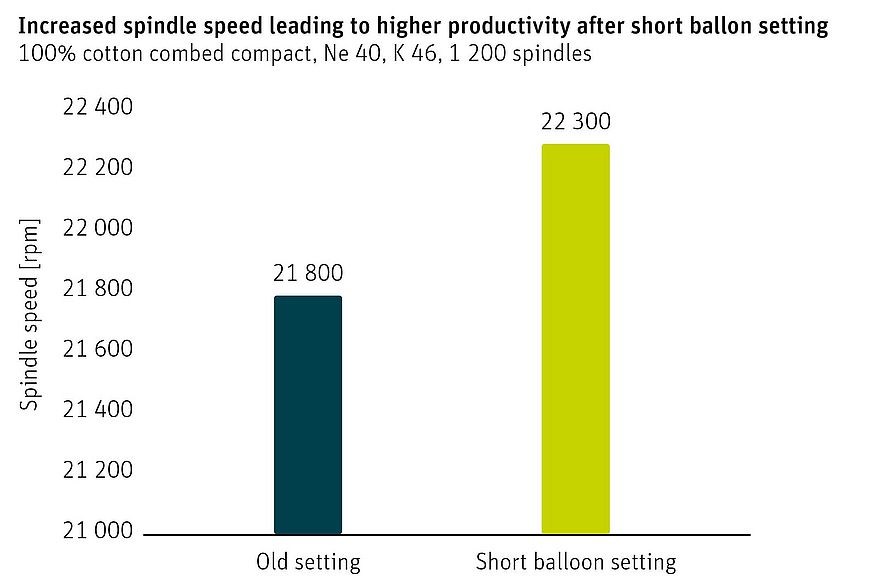

Masood Fabrics Limited in Pakistan enhanced the performance of eight compact-spinning machines K 46 with the support of Rieter. The short-balloon setting upgrade enabled the spinning mill to increase the spindle speed by 500 rpm while reducing yarn breaks from 60 to 50 per 1 000 spindle hours. This boosted productivity by 2.5%.

The challenge: How to increase spindle speed without creating more yarn breaks

Masood Fabrics Limited operates eight Rieter compact-spinning machines K 46, installed in 2017, dedicated to produce high-quality compact yarn at peak productivity. The customer sought a solution to further enhance machine productivity. The primary goals were to increase spindle speed while maintaining existing yarn break levels and ensuring consistent yarn quality. Although the machines were operating smoothly, the customer aimed to push production limits to achieve greater operational and cost efficiency.

The solution: Short-balloon upgrade to boost speed and reduce yarn tension

Rieter proposed the short-balloon setting upgrade, a solution designed to shorten the balloon height during cop build-up. This innovative upgrade balances the various balloon forces throughout the cop build-up process. By reducing the yarn balloon’s diameter and circumferential speed, the short-balloon setting upgrade lowers yarn tension. This enables an increase in spindle speed and offers the possibility of reduced yarn breaks.

The implementation of short-balloon setting in the existing compact-spinning machine K 46 has resulted in a 2.5% production increase. Moreover, the reduction in yarn breaks ensures reduced operators’ workload and smoother machine performance.Malik Asad Ullah, Technical Director of Masood Fabrics Limited (Spinning Unit), Pakistan

The benefits: More speed, fewer breaks, better efficiency

With the implementation of the short-balloon setting upgrade, Masood Fabrics Limited achieved a 2.5% increase in productivity. The spindle speed rose from 21 800 rpm to 22 300 rpm for a yarn count Ne 40, cotton combed compact yarn production. Additionally, the reduction in yarn breaks from 60 to 50 per 1 000 spindle hours contributed to increased machine efficiency. This successful implementation highlights Rieter’s commitment to enhancing machine performance and delivering value to customers.

DOWNLOAD

About Masood Fabrics Limited

Founded in 1990, Masood Fabrics Limited is a vertically integrated textile leader in Pakistan, excelling in spinning, weaving, home textiles and apparel. With over 70 000 spindles and a diverse yarn portfolio, the company produces premium fabrics, towels, and garments. With a monthly production capacity of up to 2 700 tons of yarn, Masood Fabrics is renowned for its top-quality weaving yarn. Backed by cutting-edge technology, stringent quality control, and a strong export presence, the company remains committed to innovation, sustainability and excellence in the global textile industry.