Description

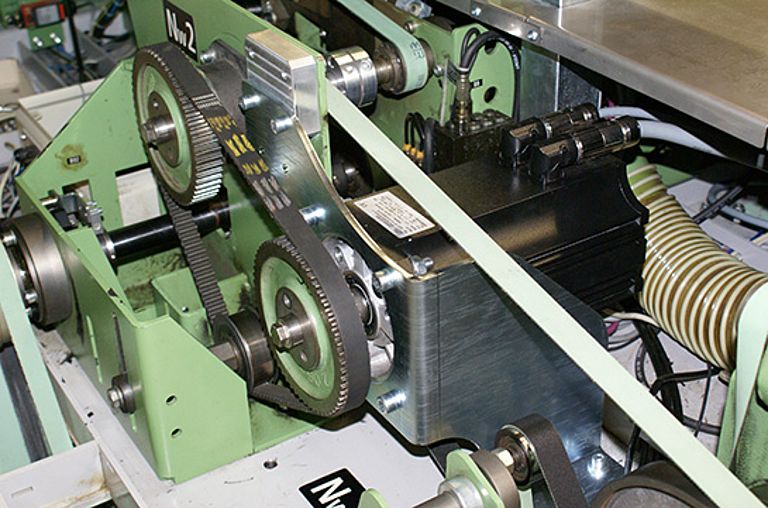

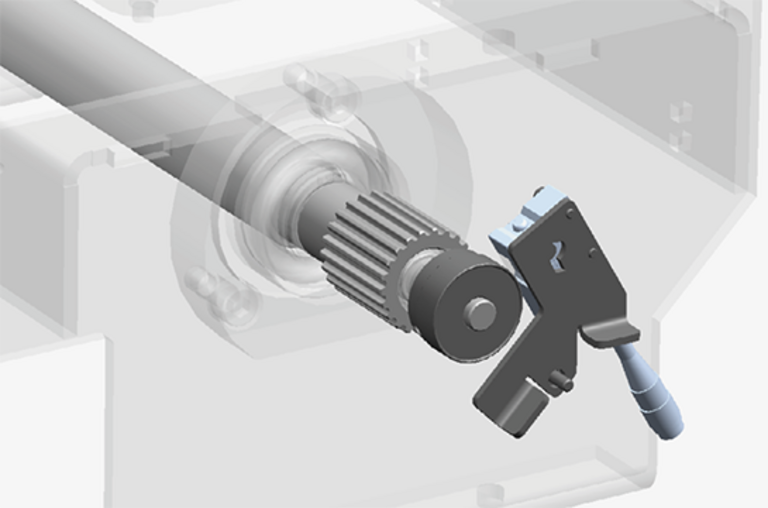

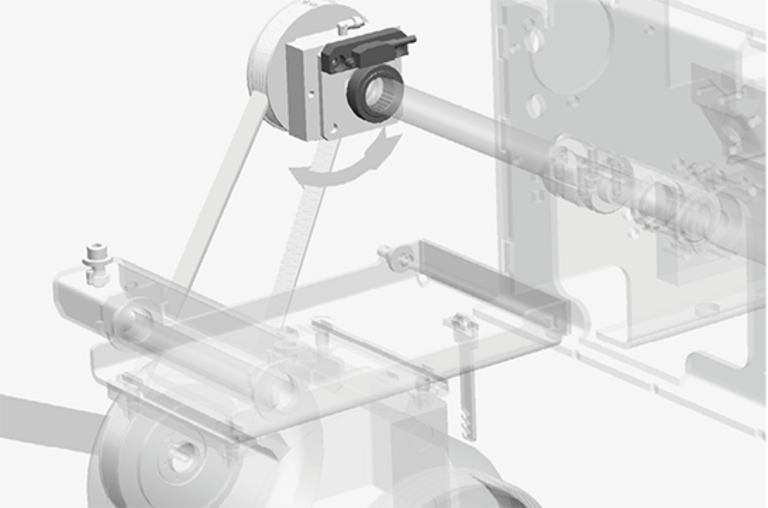

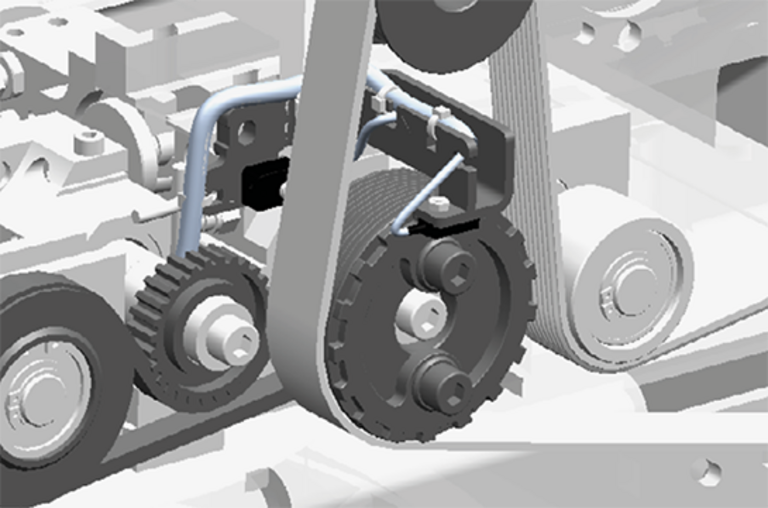

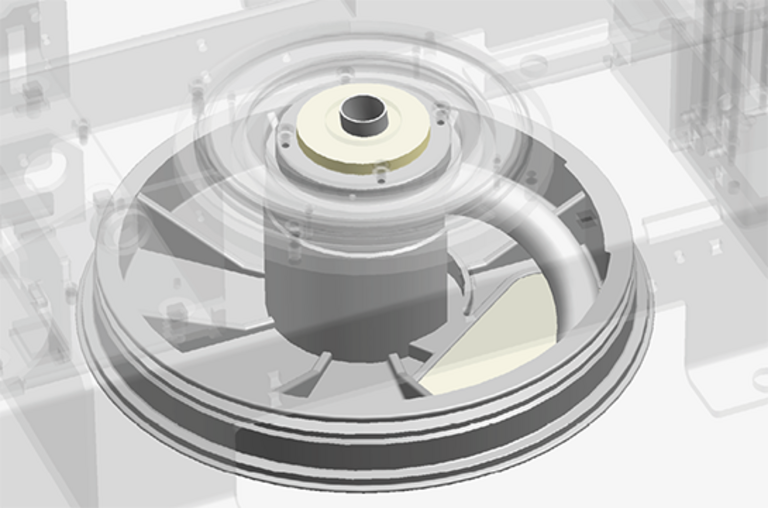

If the draw frame has come of age and some repairs are due, an overhaul strategy is key. In this case, Rieter recommends upgrading the SERVOmotor, the sensors and the fibre touching parts to optimize production, reduce downtime and save maintenance costs.