Restoring original quality

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

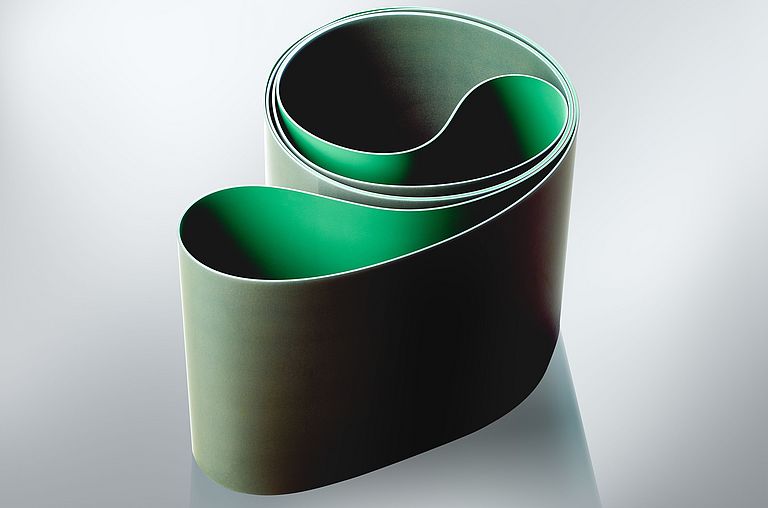

Designed to deliver exceptional performance in the lap preparation process, the Rieter OMEGAlap belt ensures homogeneous lap build-up and better fiber orientation. The OMEGAlap belt enables superior lap quality even at the highest production speeds.

Rieter nippers are adapted exactly to the combers and ensure smooth processing of batt weights of up to 80 g/m. High-precision clamping of the lap in combination with the optimized motion of the circular and top combs results in ideal combing action across the entire range of nip rates.

The pressure bar in the comber drafting system is an important fiber guidance element. It helps to improve the regularity of the combed sliver by also enabling the rather shorter fibers to be guided accurately. Thanks to its clip-on function, the pressure bar by Rieter is quickly removed and installed.

The CLEANcoil is an innovative coiler with patented honeycomb structure prevent deposits of finishing agent on the underside of the coiler by synthetic fibers. Two versions are available: the CLEANcoil for all applications and CLEANcoil-PES for 100 % synthetic fibers.

Upgrading with the circular comb 5030 increases the combing area by 23%. With its new clamping hub design, circular combs with 90 or 111 degrees can be installed and the comber can run with max. 400 nips/min.

Regular machine maintenance is crucial for ensuring smooth and efficient operation of spinning machinery. It safeguards investments and prevents unexpected breakdowns. Rieter’s modular maintenance concept enables spinning mills to follow a structured and simple maintenance approach throughout the product life cycle.

The maintenance concept comprises three kits: the mini, the performance and the overhaul kit.

If the draw frame has come of age and some repairs are due, an overhaul strategy is key. In this case, Rieter recommends upgrading the SERVOmotor, the sensors and the fiber touching parts to optimize production, reduce downtime and save maintenance costs.

The top and bottom clearer lips in the draw frame drafting zone are critical to ensure consistent quality and uninterrupted

machine operation. The clearer lips support the effective removal of micro dust and short fibers that are stuck to the top

and bottom rollers and pass them on through the suction system to avoid lapping on the rollers.

Access the Rieter webshop, ESSENTIALorder, for a seamless and personalized online ordering experience. Browse and order from our extensive range of spare parts at your convenience, 24/7. Simply log in with your credentials to get started.

Don’t have an account? Contact your local Rieter representative to set one up.

Do you need more information about parts and maintenance?