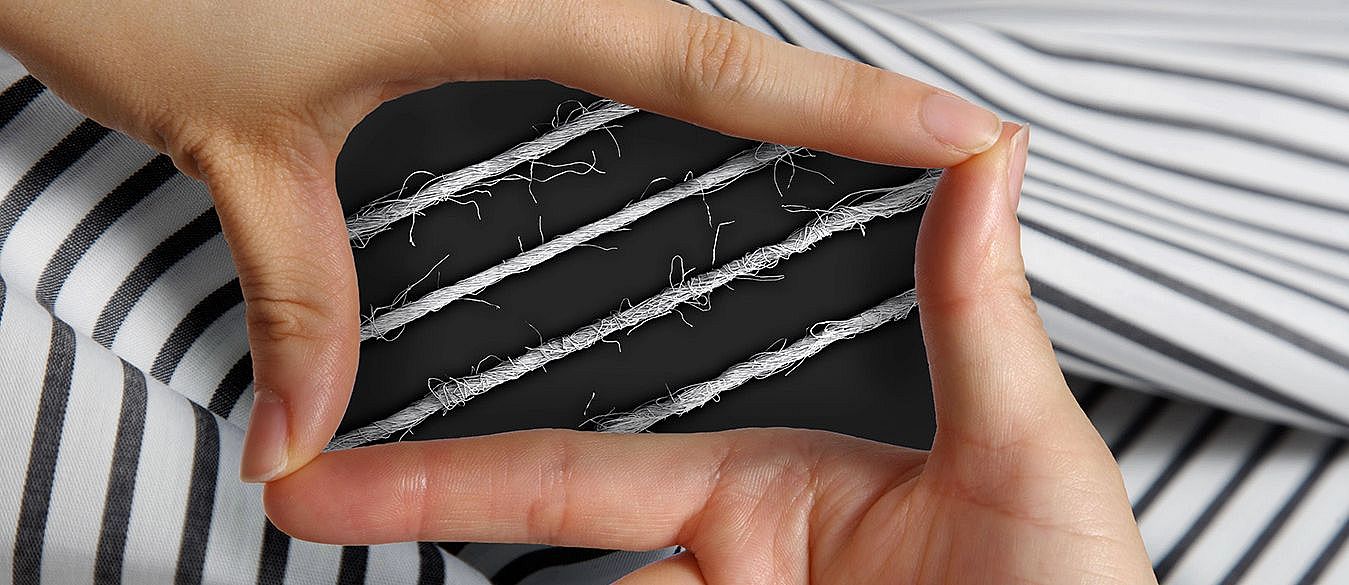

Rieter has unique expertise in textile technology. This is an important component for the optimization of processes in spinning mills and the development of new machines. Rieter customers are assisted by process recommendations and machine settings taken from the results of research.

From fiber to yarn and beyond to the textile surface – these extensive tests always take the entire process into account. This is the only way to ensure that the results are classified correctly, allowing conclusions to be made.