High precision in flexible flat clothing

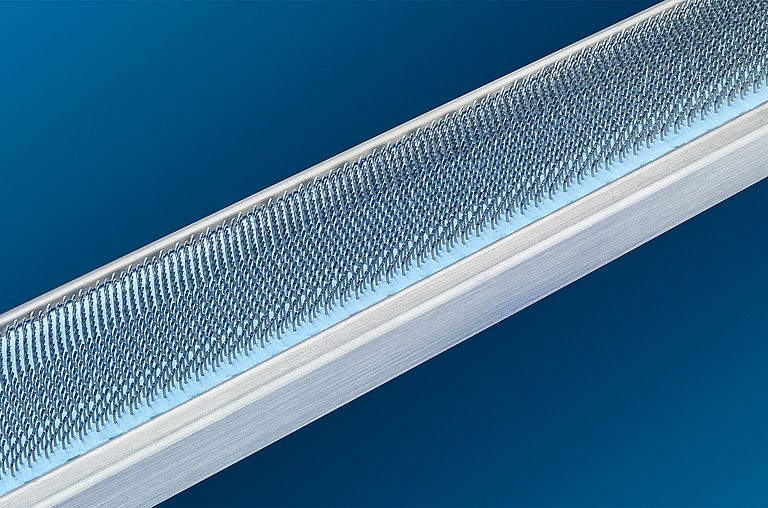

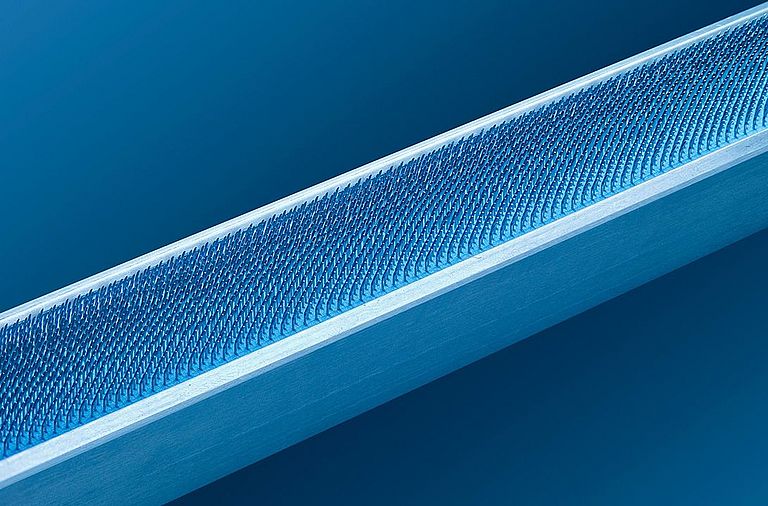

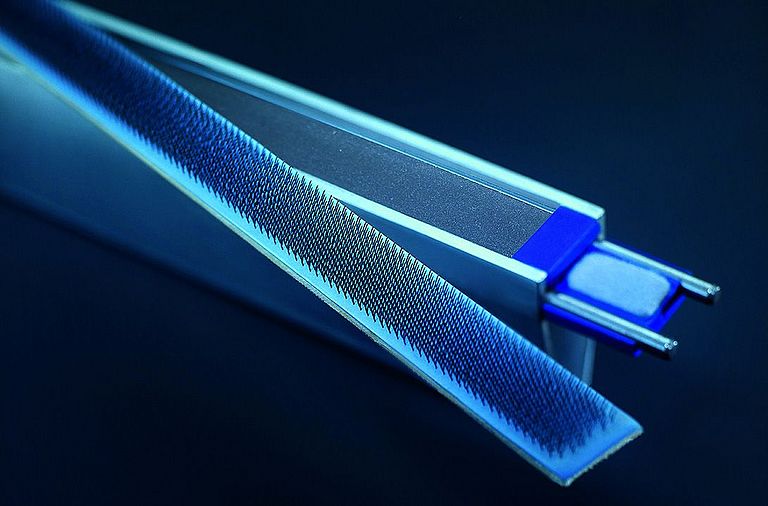

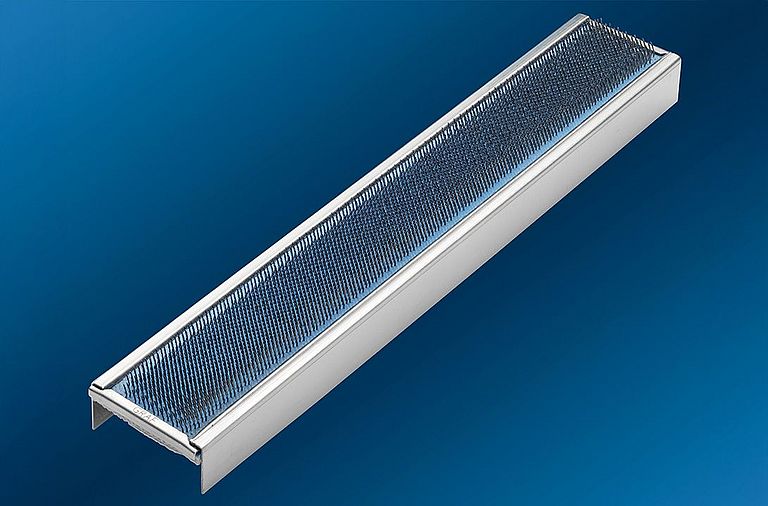

Flat clothing is used to retain the fibers so that carding through the cylinder wire works optimally. To avoid fiber damage, it is important that the flat clothing, working in perfect combination with the wire, reacts flexibly while still withstanding the high forces in place.

Everything from the foundation material to the carding wires and the finished product is manufactured at Graf. This allows Graf to deliver the highest quality and Swiss-engineered precision across the entire manufacturing process. The wide product range includes flat clothing for any carding application – from low to high-throughput productions.