Bräcker provides short-staple rings for all requirements. The right profile in combination with the renowned TITAN coating brings out the full potential of ring spinning machines.

Rings for Short-Staple Spinning

Superior rings for flexible spinning- High productivity

- Reduced spinning costs

- Long service life

- Optimal running characteristics

Coating

TITAN

The TITAN coating gives the ring an extremely wear-resistant surface. It provides minimal variation in the coating thickness and excellent coating adhesion. TITAN rings do not require a long running-in period which leads to increased productivity.

Highlights:

- Designed for high speeds to maximize output

- Fewer yarn breaks and no micro-welding

- Lifetime up to three times longer than conventional rings

Profiles

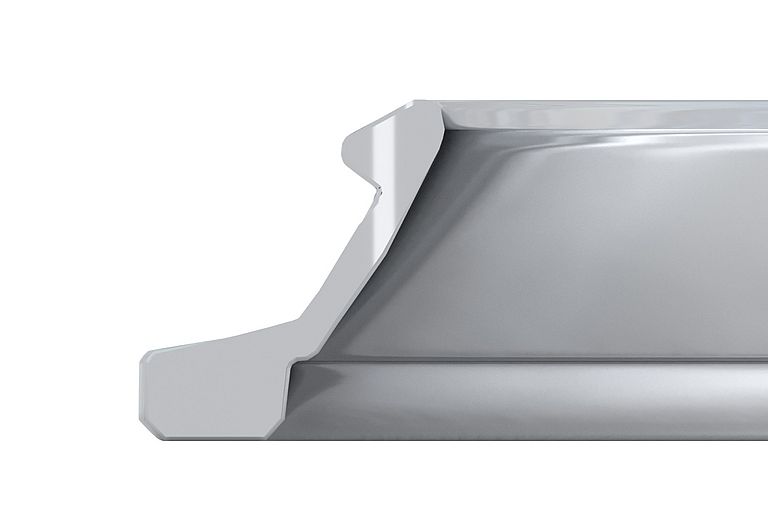

T-flange

The T-flange profile offers a punctiform contact area to the traveler. It is therefore suitable for all kinds of fibers, for ring and compact-spinning machines. The rings are available in flange ½, 1 and 2 and suitable for yarn counts Ne 4 to Ne 300.

ORBIT

The ORBIT profile features a large ring / traveler contact area. This results in good heat conductivity and allows high-speed production. It is suitable for combed cotton, polyester/cotton, blends and 100% polyester, for yarn counts Ne 12 to Ne 140 (depending on the fiber quality).

Downloads

Contact

Bräcker always wants to answer queries quickly and competently.