Guiding Arm Refurbishment: A Global Success Story

Rieter’s guiding arm refurbishment for ring and compact-spinning machines ensures consistent yarn quality, enhanced machine performance and extended lifetime. Since 2017, over 683 000 guiding arms have been successfully refurbished across 11 countries, delivering proven value to spinning mills worldwide. This cost-effective and reliable solution restores the original precision and efficiency of the drafting system.

The guiding arm in the drafting zone of ring and compact-spinning machines plays a pivotal role in ensuring high production and consistent yarn quality. Known for its simple construction and user-friendliness, the guiding arm is designed to produce constant quality and to withstand years of operation. However, components like pressure hoses, top levers and pressure saddles wear out over time. This leads to load variation, random lifting of guiding arms and yarn quality inconsistencies.

These issues can cause undrafted roving, fiber lapping on top and bottom rollers, increased yarn breaks and quality inconsistencies from spindle to spindle. To compensate for these issues, customers have had to maintain higher drafting loads.

A proven drafting system known for its versatility and adaptability

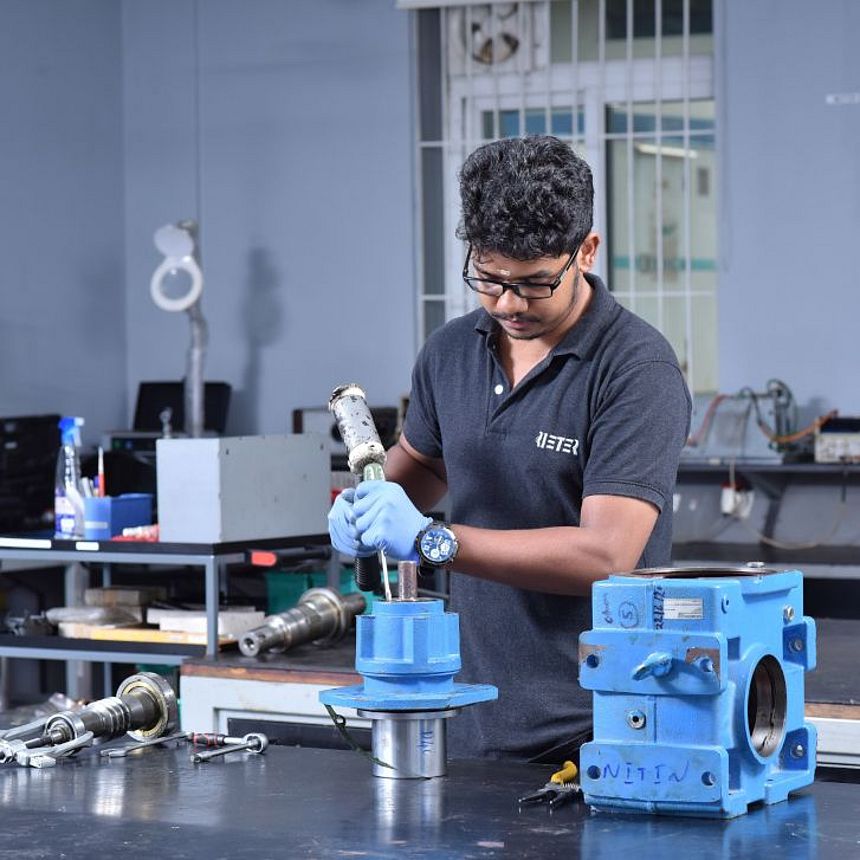

Rieter guiding arm refurbishment replaces worn-out parts with high-quality components, restoring uniform load distribution across the machine. Rieter recommends this refurbishment every eight to ten years to maintain optimal machine performance. It not only restores the original performance but also significantly enhances the yarn quality and extends the lifetime of the spinning machinery.

We have refurbished guiding arms in our six Rieter compact-spinning machines K 43. The improvement in the yarn quality and productivity levels achieved is commendable. The reduction in winding cuts has also been significant.D Venkadesan, General Manager, Sri Jayajothi and Company Private Ltd., India.

The importance of guiding arm refurbishment

Rieter’s guiding arm refurbishment supports the sustainability goals of spinning mills by extending machine lifetime and minimizing waste. Further benefits are:

- consistent yarn quality due to uniform load distribution,

- increased productivity due to reduced yarn breaks,

- energy savings due to reduced compressed air usage and

- improved winding machine efficiency with less yarn faults and winding cuts.

The guiding arm refurbishment has transformed our operations, reduced energy consumption and improved yarn quality. It’s a sustainable solution that we highly recommend.Sait Karaca, Maintenance Manager, Karteks Tekstil, Türkiye

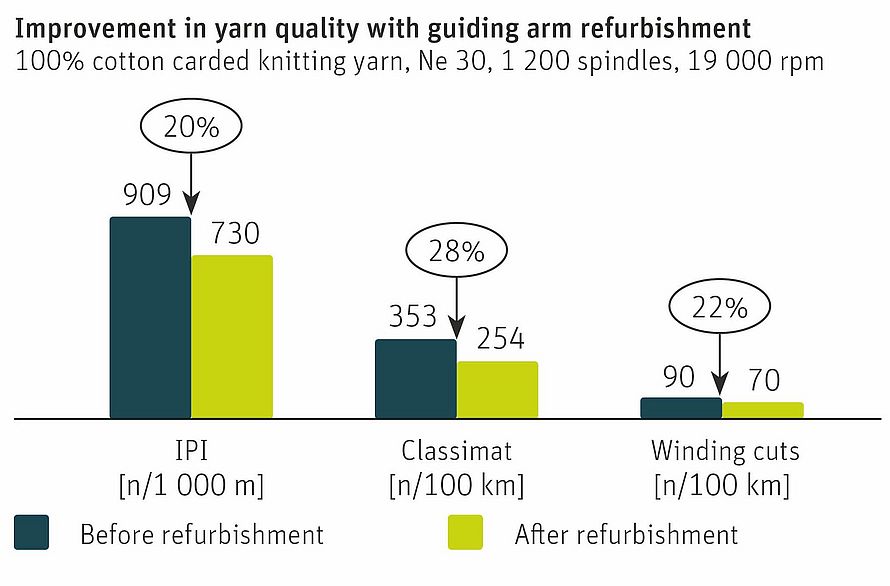

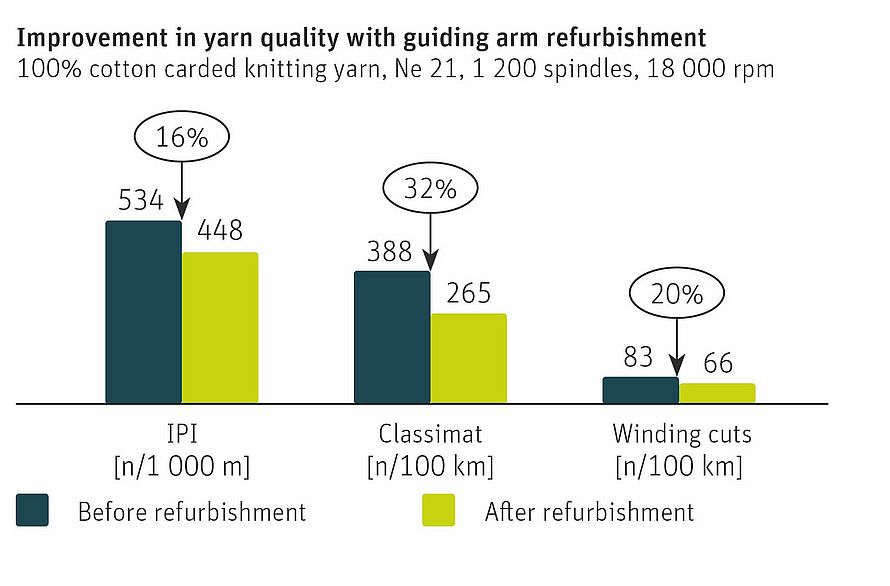

The graph below shows a recent case study that highlights remarkable improvements in yarn quality and winding cuts after guiding arm refurbishment. The refurbishment was performed for processing 100% cotton carded knitting yarn (Ne 21 and Ne 30). The results include up to 20% reduction in yarn imperfections (IPI), up to 32% reduction in classimat faults and 22% reduction in winding cuts. This refurbishment not only reduces yarn faults but also reduces operator workload and lowers energy consumption due to fewer yarn breaks.

The refurbishment has significantly improved both quality and efficiency of our ring spinning machine. The machine operation is now more economical, thanks to the Rieter repair service team.Uğur Gündoğan, General Manager, Kipaş Tekstil, Türkiye