Automation

Automation presents real opportunities for spinning mills. Not only does it use resources more efficiently. It also helps improve the quality of work. Repetitive and dull tasks are left to machines, so people can focus their energy on things that enrich their jobs and add value to the business. Rieter offers automated, customer-specific solutions for the entire spinning process from a single source.

Improving efficiency, enriching roles

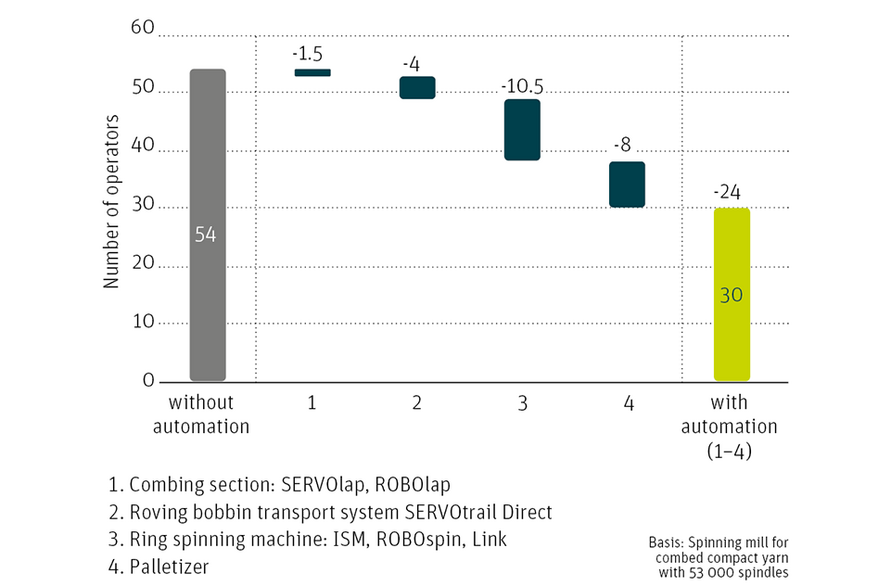

As part of a comparative study, a complete spinning mill with just under 53 000 spindles for combed compact yarn was examined. The results showed that personnel savings are possible at each process stage, with the greatest potential in the operation of ring or compact-spinning machines thanks to the piecing robot ROBOspin, the individual spindle monitoring system ISM and link – the interface to the winding machine.

People can be moved to different locations where they can have a greater impact, which makes their roles more attractive and can improve job satisfaction.

The solutions for the study included:

- Lap transport system SERVOlap

- Lap change and batt piecing system ROBOlap

- Roving bobbin transport system SERVOtrail

- Individual Spindle Monitoring system (ISM)

- Piecing robot ROBOspin

- Link system to winding machine

- Palletizer

Advantages of automation

From the blowroom to the packed yarn packages, Rieter automation solutions reduce the required number of personnel by 44% – from 54 to 30 operators in this example.

Greatest saving potential

Here are the key process stages where people resources can be saved so they can be moved to different locations.