ESSENTIALmonitor: Boosting Efficiency in the Spinning Mill

Sagar Manufacturers Pvt Ltd (SMPL), established in 2012, is an Indian manufacturer of textile products made from natural fibers and known for its high-quality standards. Sagar Manufacturers has established itself as a trusted brand in the global textile market, using the latest technology to produce world-class yarns and knitted fabric. This technology includes ESSENTIALmonitor, one of the modules of the Rieter Digital Spinning Suite. A.K. Saini, Chief General Manager (Operations) at Sagar Manufacturers, uses the system to further improve processes in the spinning mill.

The Challenge

The textile industry faces numerous challenges in today's market environment. The rising costs of raw material, energy, and labor make it difficult to maintain profitability. At the same time, there is growing competition from low-cost producers, both domestically and abroad. In addition, fast fashion trends and the need for speed to market require spinning mill owners to continuously innovate and improve efficiency in order to meet the demands of consumers.

The Solution

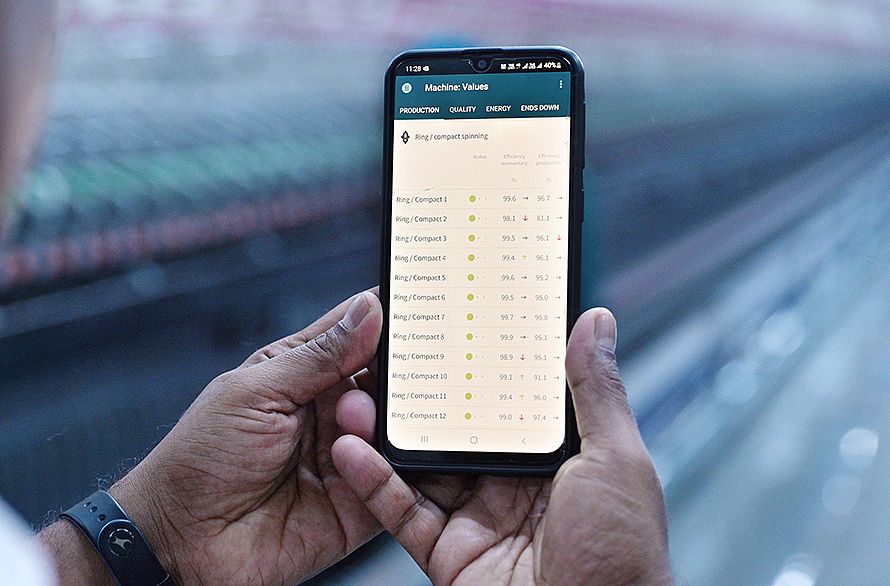

To support its operations, Sagar Manufacturers relies on digital solutions. They installed Rieter’s ESSENTIALmonitor in 2021 and use the individual spindle monitoring ISM premium on their ring and compact-spinning machines. This system combines advanced monitoring and control technology to optimize spinning production processes.

ESSENTIALmonitor offers real-time monitoring of machine parameters, which allows shift supervisors to always keep an eye on the performance of their machines. This ensures that any issues can be quickly identified and addressed before they escalate into major problems.

One of the key features of ESSENTIALmonitor is its ability to monitor stop events which occur at the ring spinning machine. This helps shift supervisors to identify the root cause of production disruptions, allowing them to take the necessary steps to resolve the issue. The system also monitors low-performance machines and spinning positions, which helps to identify any areas where improvements can be made.

The Customer’s Benefits

The implementation of the ESSENTIALmonitor with ISM premium brought numerous benefits to Sagar Manufacturers:

- An increase in productivity of 1.5%

- A reduction in manpower requirements of 10%

- A decrease in hard and soft waste of 10% and 2.5% respectively

- The plant utilization is expected to improve by 0.1%

Sagar Manufacturers is delighted by the performance optimization achieved through the full use of ESSENTIALmonitor. Especially, the improvement suggestion and threshold trigger features have helped the company to avoid stoppages and maintain quality, particularly in the second draw frame passage. Sagar Manufacturers is looking forward to more features of the Rieter Digital Spinning Suite in the future that will further optimize their spinning process.

We appreciate the support from the Rieter team very much and feel that our needs are understood. The full utilization of ESSENTIALmonitor has allowed us to optimize the performance over the entire process. We are excited to see what the future of the system holds.A.K. Saini, Chief General Manager (Operations) of Sagar Manufacturers Pvt. Ltd.