High Level of Automation for High-Quality Compact Spinning

Naveen Rander, Director of Sri Bhagirath Textiles

Sri Bhagirath Textiles, an Indian premier yarn manufacturing company, offers a wide range of products including 100% synthetic and cotton yarn as well as blends produced with ring spinning and compact-spinning technology. The company has a fully automatic cotton ginning plant and aims to invest in the key pillars of technological advancements, technical infrastructure and the skills of its employees. With the latest Rieter compact-spinning machines K 47 directly linked to Rieter winding machines Autoconer X6, Sri Bhagirath meets the rising customer demands for high-quality compact yarns and benefits from a high level of automation.

The Challenge

A challenge for Indian spinning mills is the increasingly difficult recruitment of qualified employees. In addition, the textile value chain is characterized by tough competition in terms of raw material costs, yarn prices and the fulfillment of demanding quality criteria. The unstable availability of good fiber quality makes it challenging to continuously spin yarns on highest quality level, and run the machines with satisfying efficiency.

The Solution

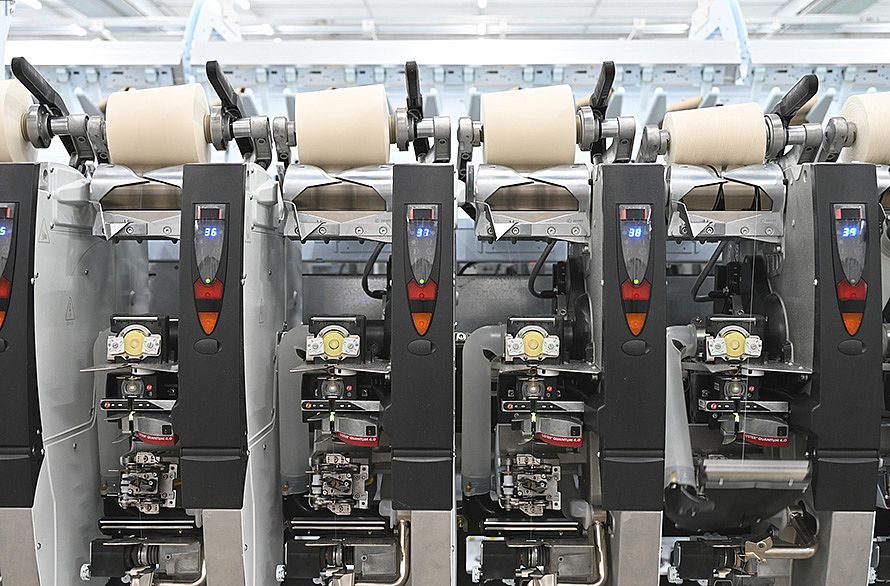

Compact yarns are characterized by high tenacity, even yarn structure, low hairiness and high yarn density. This results in smooth downstream processing. As it ensures the highest quality for their application, Sri Bhagirath decided to opt for the compact-spinning process again when modernizing their spinning mill. Now they have started the production with 17 brand-new Rieter compact-spinning machines K 47, which are directly linked to Rieter winding machines Autoconer X6. With this investment Sri Bhagirath can fulfill its expectations concerning yarn quality and the high automation level makes the mill less dependent on manual operator work. Due to the better integration of the fibers in the yarn during compact spinning, the raw material utilization is higher than in convential ring spinning.

The Customer's Benefits

With the direct link of the Rieter compact-spinning machines K 47 to the Rieter Autoconer X6, Sri Bhagirath has opted for a high level of automation and a one-source spinning mill installation.

The K 47, equipped with unique sieve drum compacting system, energy-efficient technology components and the one-duct system for suction, produces high-quality compact yarns with much less energy for compacting in comparison to other solutions in the market. Monitoring systems, such as air guide element Detect and the integrated individual spindle monitoring system ISM basic, check the running properties of each spinning position. This ensures the highest level of yarn quality, machine efficiency and reduces operator workload. Thanks to the semi-electronic drafting system, the operator effort and time for parameter setting and machine adaption is reduced to a minimum.

The latest generation of Autoconer X6 machines is a significant step towards intelligent and reliable automation. Sri Bhagirath now is much more independent from the availability and reliability of operators, and can process high-quality compact yarns on a very efficient and energy-saving level. The self-optimizing functions of the material flow (Intelligent Cops Sharing), the high cycle rates of the unique optic tube inspector and the efficient upper yarn gripping supported by the unique Smartjet are important advantages for a nearly autonomous operation of the machines. Not to forget the integrated online-quality monitoring system SPID which guides the operator to an off-standard spinning position in order to make corrections after the winding unit has detected faulty cops. Operators can focus on monitoring functions.

With the new open prism technology, Sri Bhagirath can cover the complete yarn count range with only one prism (OZ1) with nearly no splice parameter variations and achieves excellent splice quality for its compact yarns. The consistent splice quality with an average splice strength of more than 95% fulfills the high quality requirements.

The high-level automation with integrated monitoring systems guarantees both: independency from operators and highest quality of our compact yarns. We have complete confidence in Rieter’s spinning and winding expertise. We see the performance advantages because everything comes from a single source: fast machine installation, excellent technological support and customized service.Naveen Rander, Director of Sri Bhagirath Textiles

Download

About Sri Bhagirath Textiles

Sri Bhagirath Textiles Ltd. was established in 1996, and is today an Indian premium yarn manufacturing company, located in Central Indian city of Nagpur, (Maharashtra). What started as a small textile unit, has been growing over the years into an 80 000 spindles company, with additionally 2 200 rotor spinning positions, 24 TFO (doubling) units, 40 knitting machines, and an own ginning plant. Sri Bhagirath offers a wide range of products: Cotton, Cotton/Viscose, Cotton/Modal yarns, and fabrics. To guarantee high customer satisfaction, Sri Bhagirath Textiles invests continuously in the key pillars of technological progress, improves their technical infrastructure, and trains their people skills. The company is working as a highly professional organization with strong process and quality control.