High-Speed Production with G 37 for Polyester-Cotton Blend

Shiqiao Qi, Factory Director of Sichuan Dekai Special Fiber Co., Ltd.

Sichuan Dekai Special Fiber Co., Ltd., located in Deyang City, Sichuan Province, mainly produces recycled polyester fibers and yarns. Dekai has a production capacity of nearly 100 000 ring spindles and 1 728 rotor positions. After investing in 25 Rieter ring spinning machines G 37, the company improved productivity and the quality of its products.

The Challenge

China’s domestic spinning market is under pressure. Factors like supply-chain disruptions and the international economic environment have dampened consumer demand while export orders have slowed. On top of this, rising processing costs and lower yarn prices are squeezing profit margins.

To cope with these challenges, Dekai decided to focus on higher productivity to reduce the conversion costs per ton of yarn. Additional requirements included low energy consumption, consistent yarn quality and stable running performance of the machines.

The Solution

The Rieter ring spinning machine G 37 with its stable and solid intermediate drive achieves maximum productivity with 1 632 spindles. High quality components ensure consistent yarn quality and higher machine efficiency. When producing a blended yarn from 65% polyester and 35% combed cotton with yarn count Ne 32, the G 37 achieves stable high-speed production at Dekai. The drive system as well as the efficient spindle and suction system especially keep the energy consumption low with high productivity. The stable yarn quality meets the customers’ requirements, which enhances the reputation of Dekai in the market for high-quality blended yarns from polyester and cotton.

The Customer's Benefits

Thanks to the high spindle speed of the G 37, production has been increased significantly. One G 37 was equipped with the Orbit spinning ring and achieved a maximum speed of 24 500 rpm and an average speed of 23 500 rpm with the polyester-cotton blend. This is 24% faster than the competitor machine and brings additional benefits:

- With the increase of output value, the annual profit can be increased by CNY 84 per spindle and year based on the price of a polyester-cotton yarn Ne 32.

- The yarn quality is stable with few ends down, so the operator demand is reduced. The saving in labor cost is equivalent to an increase in profit of CNY 10 per spindle and year.

- Improving the production efficiency of the machine by low failure rates and stable doffing efficiency increases the profit by CNY 16 per spindle and year.

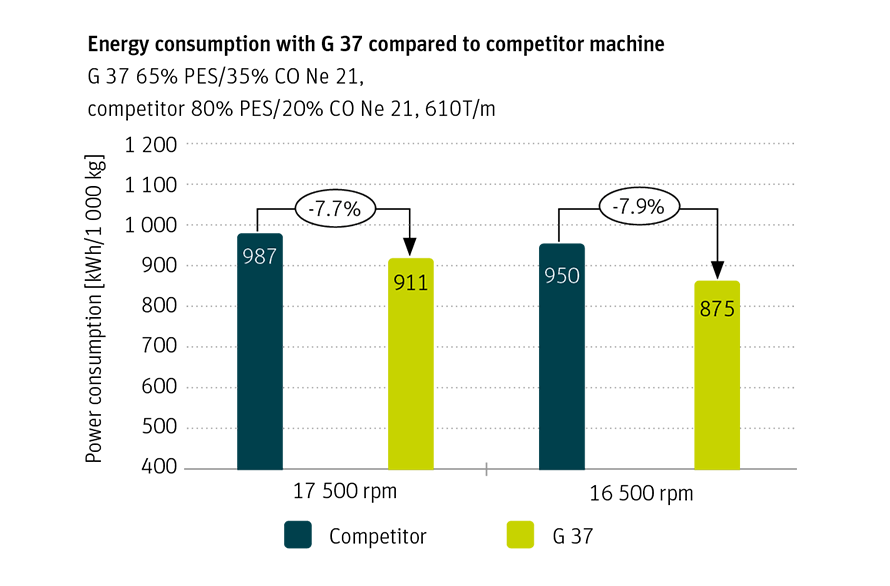

- At the same spindle speed, the energy consumption per ton of yarn can be reduced by 7-13% compared to the competitor machine.

In addition, Rieter has supported the customer with a project team, handled problems quickly and gave strong production management support. Together, Dekai and Rieter were able to unlock the full potential of the G 37 and reach top speeds.

We believe that Rieter’s advanced machinery and spinning technology will help us to become the new benchmark in yarn production in the industry. Proof of this is the fact that productivity far exceeds our expectations and yarn quality is recognized by downstream customers.Shiqiao Qi, Factory Director of Sichuan Dekai Special Fiber Co., Ltd.

Download

Sichuan Dekai Special Fiber Co., Ltd.

Sichuan Dekai Special Fiber Co., Ltd., located in Deyang City, Sichuan Province, mainly produces recycled polyester fibers and yarns. Dekai has a production capacity of nearly 100 000 ring spindles and 1 728 rotor positions. The company produces blended yarn from polyester and carded cotton or combed cotton in a count range of Ne 20 to 60. The end products are work clothes and military uniform. With a wide range of yarn types and excellent yarn quality, Dekai has secured a share in the market for high-end polyester-cotton blended yarn.

Sichuan Dekai Special Fiber Co., Ltd.

Zhongjiang Xian

618 100 Deyang City

China