IGS-classic – A Unique Solution for Consistent Quality

Maintenance of card clothing is essential to achieving consistent sliver quality. IGS-classic stands for integrated grinding system. Exclusively available for Rieter cards, IGS-classic satisfies customer requirements, including an increase in the cylinder wire lifetime of up to 20%. IGS-classic keeps the cylinder wire constantly sharp, almost without human interference.

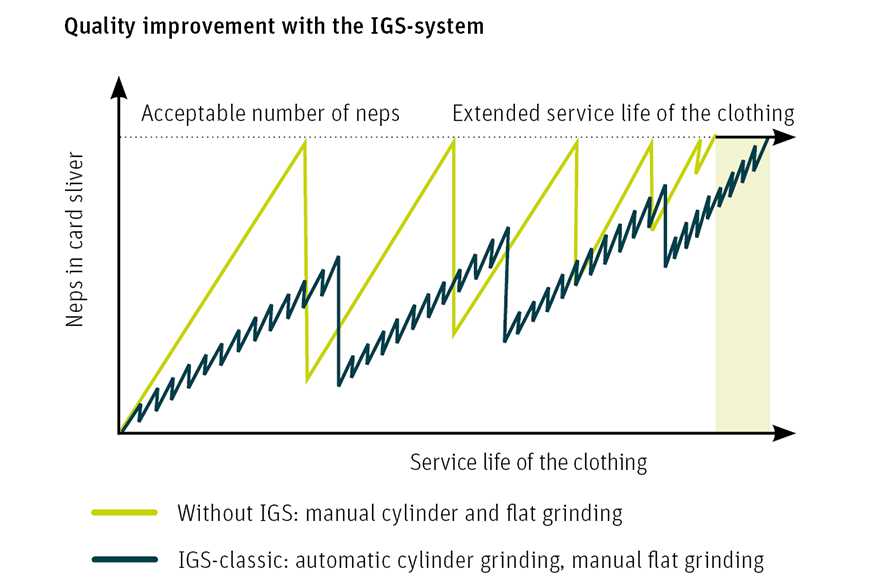

The card clothing consists of metallic wires that undergo various mechanical stresses. The carding sliver quality deteriorates over a period of continued operation as the sharpness of the wires lessens over time. Regular grinding to re-sharpen wire points is necessary to maintain quality. This is usually done at fixed intervals manually and forms part of the scheduled maintenance activity in every spinning mill. The conventional manual cylinder wire grinding process requires two skilled technicians and stops production for at least three hours during every resharpening schedule.

Improved carding efficiency and prolonged wire life

Rieter’s IGS-classic automates the process of cylinder wire grinding which makes it unique in the market. The inbuilt grinding stone automatically moves across the cylinder clothing during machine operation and sharpens the cylinder wire at fixed intervals. This intense grinding operation maintains the sharpness of the wire throughout its lifetime and therefore provides consistent carding efficiency by effectively removing impurities and neps. IGS-classic cylinder wire grinding is performed up to 400 times over the expected service life of the clothing. It is possible to adjust the grinding cycle time and intervals depending on the raw material, process and customer requirements.

With the IGS-classic system, the manpower and downtime of the machine are reduced as the grinding takes place during machine operation. The computer controlled automatic grinding system conducts a uniform sharpening of the wires without the involvement of operators or maintenance personnel. This ensures consistent sliver quality throughout the lifetime of the clothing. In addition, the wire lifetime is extended by up to 20%.

Rieter offers IGS-classic upgrades for older card machine models like C 60, C 601 and C 70.

IGS-classic is a unique solution that fulfills our requirements in many aspects. Having the IGS system in our card enabled us to achieve a consistent sliver quality and extend the lifetime of our cylinder clothing. This feature is extremely valuable to us.Surinder Kumar Mahajan, Director, Aarti International, India