Restoring original quality

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

The wobble disc take-off roller is made out of 39 wobble discs which are welded on a seamless precision pipe which is forming the take-off roller. This take-off roller is used in all current UNIflocs and available also for upgrades.

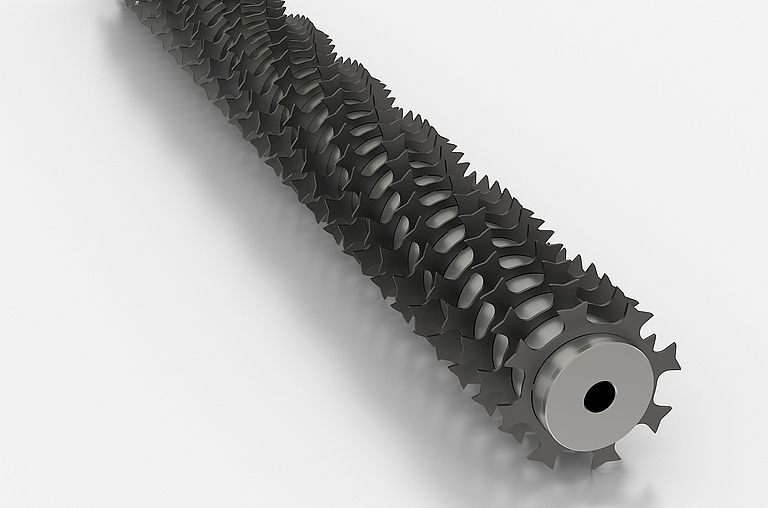

The spiked lattice removes tufts simultaneously from all layers. Its improved design and optimum needle positions allow intensive and gentle opening of the raw material. The superior reinforcement of the belts makes the spiked lattice wear-resistant. The special links and the aluminum rails ensure long service life.

Regular machine maintenance is crucial for ensuring smooth and efficient operation of spinning machinery. It safeguards investments and prevents unexpected breakdowns. Rieter’s modular maintenance concept enables spinning mills to follow a structured and simple maintenance approach throughout the product life cycle.

The maintenance concept comprises three kits: the mini, the performance and the overhaul kit.

Card performance depends on the individual process steps that ensure high production rate as well as a high discharge rate of waste and short fibers. To meet these demands while keeping the card at the cutting edge of technology, Rieter proposes to optimize the individual process zones: chute, licker-in, main cylinder, flat and doffer unit. The Q-package, which optimizes the pre- and post-carding zones located around the main cylinder, is a particular highlight as it helps achieve better sliver quality.

Access the Rieter webshop, ESSENTIALorder, for a seamless and personalized online ordering experience. Browse and order from our extensive range of spare parts at your convenience, 24/7. Simply log in with your credentials to get started.

Don’t have an account? Contact your local Rieter representative to set one up.

Do you need more information about parts and maintenance?