Ring and Compact-Spinning Performance Kit Boosts Productivity and Yarn Quality

A performance kit for better results: Sreedhara Textiles Pvt. Ltd. team and Rieter after-sales team

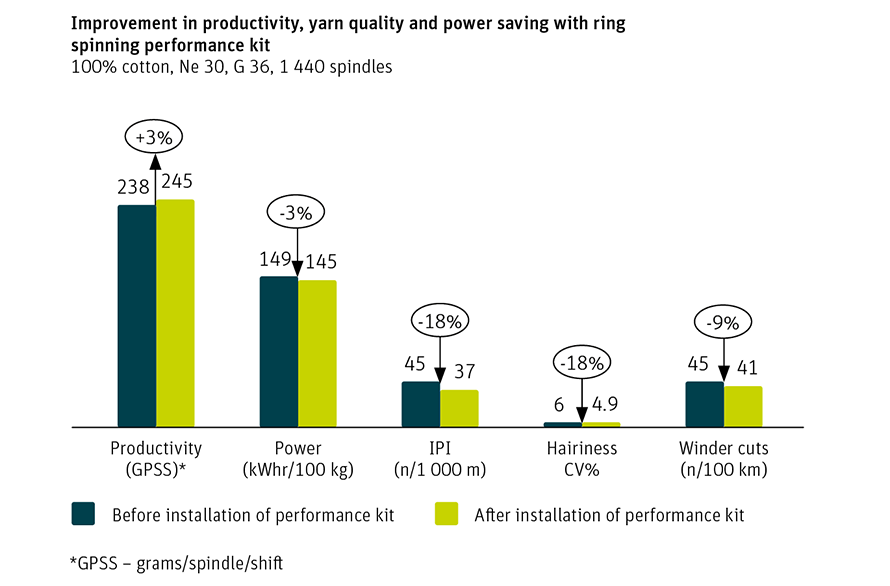

Sreedhara Textiles Pvt. Ltd., India, has upgraded its ring spinning machines G 32 and G 36 with a ring spinning performance kit. They achieved a 3% production increase coupled with reductions of 3% in power consumption, 18% in yarn imperfections and 9% in winder cuts.

Maintenance of ring and compact-spinning machines plays a vital role in achieving a desired and consistent performance output throughout the machine lifecycle. Some ring spinning machine components may look small and simple, but the impact they have on the machine's performance is huge. For example:

- Improper movement of the ring rail due to failure of the bearing in the tape tension roller can lead to poor cop buildup, resulting in increased winder cuts.

- The separator with groove marks can lead to an increase in yarn breaks.

- The variable tension of the torsion spring guiding for the bottom apron can lead to deterioration in yarn quality with an increase in imperfections.

- The improper functioning of the spindle break will tend the operators to hold the tube for stopping it, which may lead to spindle and tube failures and in addition to yarn quality deterioration.

Sreedhara, one of the many prestigious Rieter customers based in Southern India, installed ring spinning machines G 32 and G 36 during 2016. They faced the following challenges while trying to increase the spindle speed to achieve higher productivity:

- higher yarn breaks,

- improper cop buildup leading to poor winding performance,

- more objectionable faults and

- higher yarn imperfections and hairiness CV% value.

Performance Kit: A Powerful Maintenance Solutions Package

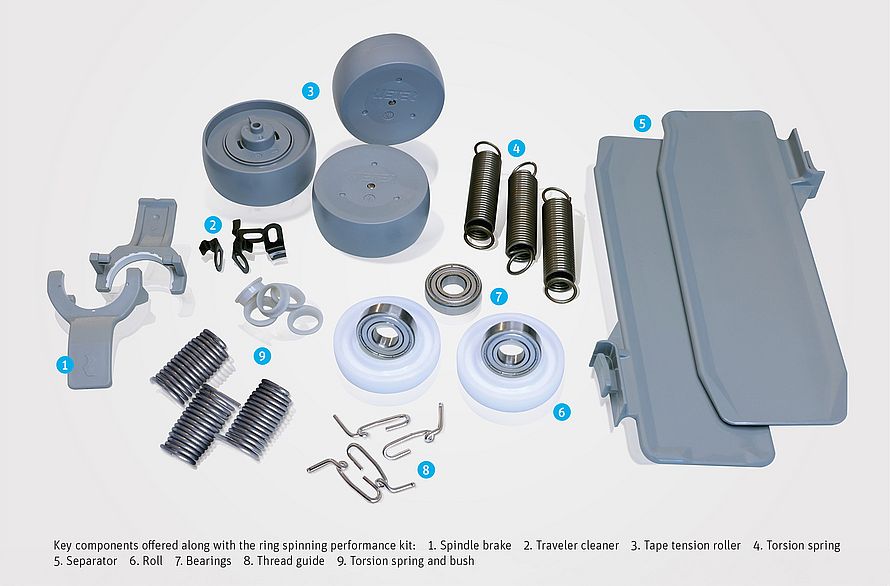

Replacing single parts is a temporary solution that will not serve the purpose or yield the expected results. Rieter's after-sales team analyzed the situation and recommended the customer to invest in the performance kit: a maintenance solution package customized for ring and compact-spinning machines. The performance kit consists of key components and parts in the drafting and spinning zones. Rieter suggests replacing them after their lifespan of approximately seven years.

The drafting zone components ensure proper stretching and drawing of the roving for the highest quality, while the spinning zone components enable an even cop buildup. The components are strategically grouped, considering their criticality and impact on the machine's performance. Replacement of these parts will help increase the spindle speed for high productivity, achieve better yarn quality, lower power consumption and maintain the smooth performance of the machine for several years.

This package of components and parts saves installation time and cost. The kit is pricewise attractive compared to purchasing individual components. Sreedhara ordered performance kits for six machine quantities suitable for G 32 and G 36.

The Performance Kit Delivers Key Improvements

The improvements are seen immediately after the installation of the performance kit in terms of productivity, yarn quality and power savings. Sreedhara achieved the following benefits:

- 3% increase in production,

- 3% reduction in power consumption,

- 18% reduction in yarn imperfections,

- 18% reduction in hairiness CV% and

- 9% reduction in winder cuts.

The between-cops variations are reduced due to the installation of new parts, resulting in uniform package quality and better performance of the winding machine. In addition, replacing the old parts with Rieter’s original parts extends the lifetime of the ring spinning machine.

After the installation of the performance kit on the ring spinning machine, we got a substantial improvement in terms of productivity and yarn quality. The variation between cops got drastically reduced, which helped improve the performance of the winding machine. We thank the Rieter after-sales team for offering this maintenance solution.Anantha Kumar, Factory Manager, Sreedhara Textiles Pvt. Ltd., India