Restoring original quality

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

Rieter offers original parts for any short staple spinning machinery, from fiber preparation to end spinning.

The high quality cots Ri-Q-Cots enable outstanding yarn quality and consistent performance throughout the entire lifetime. Grinding characteristics of the cots are favorable which means that shore hardness is retained even after grinding, leading to virtually trouble-free operation over a long period.

As a key component of the drafting zone, the Ri-Q-Bridge achieves the best yarn quality by better fiber guiding between aprons and better movement of the aprons, resulting in better CV%.

Ri-Q-Aprons stand for long service life and excellent quality. They feature great wear resistance characteristics, even under extreme conditions, which results to enhanced lifetime. The Ri-Q-Aprons are also recognized for their flexibility, allowing consistent quality over time. No matter what raw material or yarn count is spun, Rieter offers a wide range of different Ri-Q-Aprons to fulfill even the most stringent requirements.

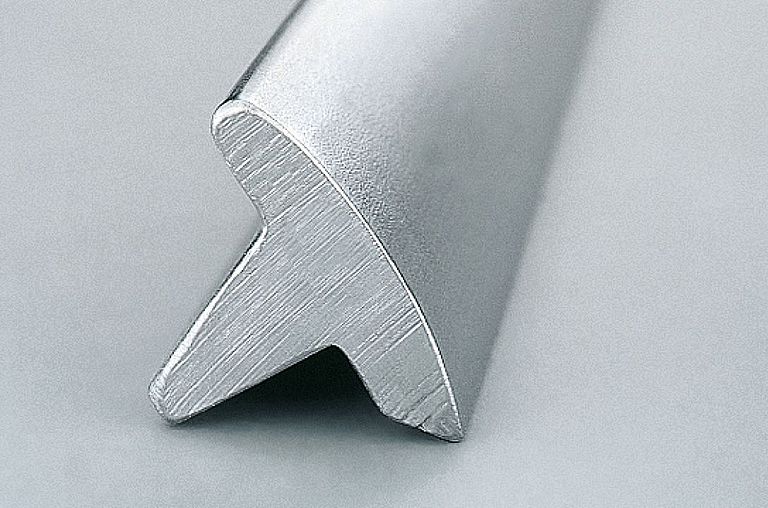

With a diameter of 30mm instead of the regular 27, the bottom roller by Rieter counteracts the build-up of fiber lap, especially with long fibers.

By means of the precise and constant air flow with the suction inserts Bright and Bright-Twin, the fibers are optimally integrated in the fiber package. The improved air flow prevents deposits of dust and fiber particles. This results in a fully compacted yarn at all times.

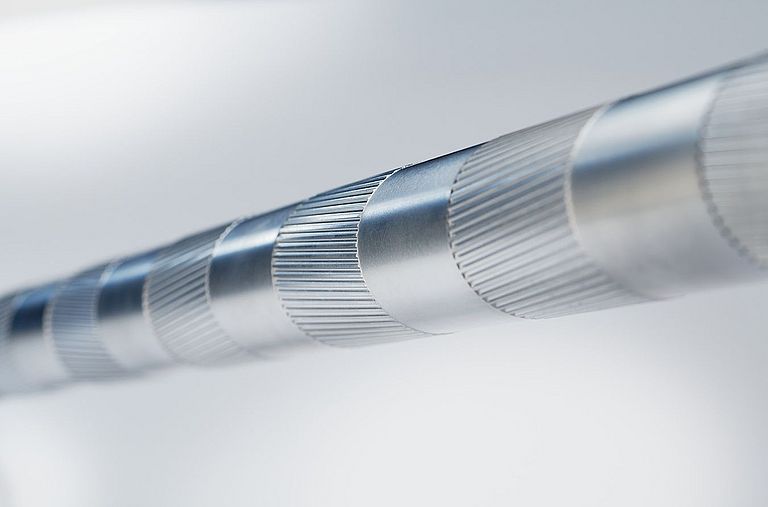

The suction drum system is the only compacting system that offers high machine efficiency without extensive maintenance and cleaning. Two different suction drums are available, one featuring a fluted surface and the other featuring a smooth surface. The selection of the suction drums depends on the yarn count produced.

Regular machine maintenance is crucial for ensuring a smooth and efficient operation of spinning machinery. It safeguards investments and prevents unexpected breakdowns. Rieter’s modular maintenance concept enables spinning mills to follow a structured and simple maintenance approach throughout the product life cycle.

The maintenance concept comprises four kits: the mini, the performance, the overhaul and the doffer kit.

The gripper membrane is an integral part of the gripper assembly. During each doffing operation, the gripper membrane will inflate and deflate to pick up and drop the cops in its position.

Rieter‘s Ri-Q-Tubes used in ring and compact-spinning machines are crucial to ensure smooth and reliable operation. Due to a special plastic blend material, the dimensional stability of the tubes remains the same throughout the lifetime. Hence, customers can expect a lifetime twice as long as that of conventional tubes.

Access the Rieter webshop, ESSENTIALorder, for a seamless and personalized online ordering experience. Browse and order from our extensive range of spare parts at your convenience, 24/7. Simply log in with your credentials to get started.

Don’t have an account? Contact your local Rieter representative to set one up.

Do you need more information about parts and maintenance?