High Flexibility and Consistent Quality with Comber E 90

Norfil was founded in the state of Paraiba, Brazil, and is a family-owned business, currently managed by the second generation of the family. Thanks to continuous investments in technology and automation, the company now produces 2 400 tons of yarn per month. Using raw material from their own cotton plantation, Norfil manufactures high-quality yarn for the apparel industry, with combed cotton as their main product. In order to meet the high quality requirements also in the future, Norfil purchased new Rieter combers E 90.

The Challenge

Norfil invests in new machinery every 12 years, because a modern plant is a prerequisite for fulfilling its productivity and quality requirements. In this context, the company was looking for a new comber that could deliver consistently high quality. But that is not all: it should also have the capability to produce all quality levels with high consistency. Experts know that this is the bigger challenge. Norfil also wanted to be able to change the noil level on its new comber quickly.

The Solution

The new comber E 90 meets all these requirements. It produces up to 100 kilograms of combed sliver per hour. The proven Rieter Quality Monitor (RQM), which is installed in the E 90, ensures consistently high sliver quality right where it happens. The RQM delivers exact real-time information about the sliver quality and, as a result, deviations in sliver weight and irregularities can be detected at a very early stage. The operating unit is very easy to use, which enables Norfil to flexibly change the quality requirements. The new technology components developed for the E 90 significantly reduce the noil extraction and lead to improved raw-material utilization.

The Customer's Benefits

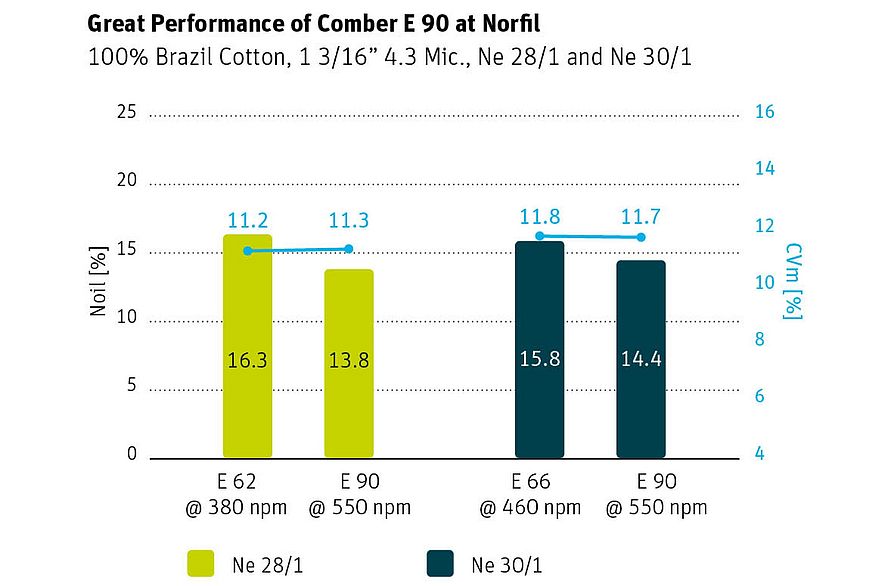

It usually takes a long time to verify the effects of changing settings on the comber in the ring yarn. Here, the RQM on the E 90 provides Norfil with maximum assurance as the company constantly receives exact and reliable information regarding the current quality level. Using the E 90, they can also quickly change the noil level from 24% to 14% – this extends their working range and saves raw material. Norfil can now produce sliver with a low noil level of 14% with maximum consistency for Ne 30 at a rate of 550 nips/min – with enough headroom to easily accelerate to 600 nips/min if needed. The operators can conveniently change the settings on the user-friendly operating unit, which ensures a quick response to changing market conditions. Thanks to the huge noil savings with the E 90, Norfil also managed to cut costs while maintaining quality. The company is very satisfied with the ongoing support from Rieter technicians throughout the project. In cooperation with Rieter technologists, Norfil was able to implement new ideas, resulting in a new combing process designed for their specific needs. The E 90 is the best solution for Norfil and it has already ordered the next batch of combers.

The new comber E 90 takes many things off our hands so that we can concentrate on our priorities. This is mainly due to the Rieter Quality Monitor (RQM). It is easily adjustable, and we can trust the settings. The comber delivers the promised quality very consistently at a high productivity rate.Fabio Borger, owner of Norfil

About Norfil S.A. Indústria Têxtil

Norfil was founded in the state of Paraiba, Brazil, and is a family-owned business, currently managed by the second generation of the family. Thanks to continuous investments in technology and automation, the company now produces 2 400 tons of yarn per month. Using raw material from their own cotton plantation, Norfil manufactures high-quality yarn for the apparel industry.

Norfil S.A. Indústria Têxtil

05038-001 São Paulo

Brazil