Upgrading the Draw Frame to Optimize Performance

Draw frames are the cornerstones of every short-staple spinning process. Nevertheless, they are subject to technical wear and tear. Rieter’s draw frame maintenance concept helps customers achieve outstanding sliver evenness, save on maintenance cost and reduce unplanned downtime.

A high-performing draw frame is the cornerstone of any spinning mill.Upgrading key components such as the levelling unit, the sensors and the fiber touching parts optimizes production, reduces downtime and saves maintenance costs. Depending on the budget and needs, there are a variety of ways to improve the performance of the draw frame. It is best to start with the SERVOdrive and the top roller upgrade.

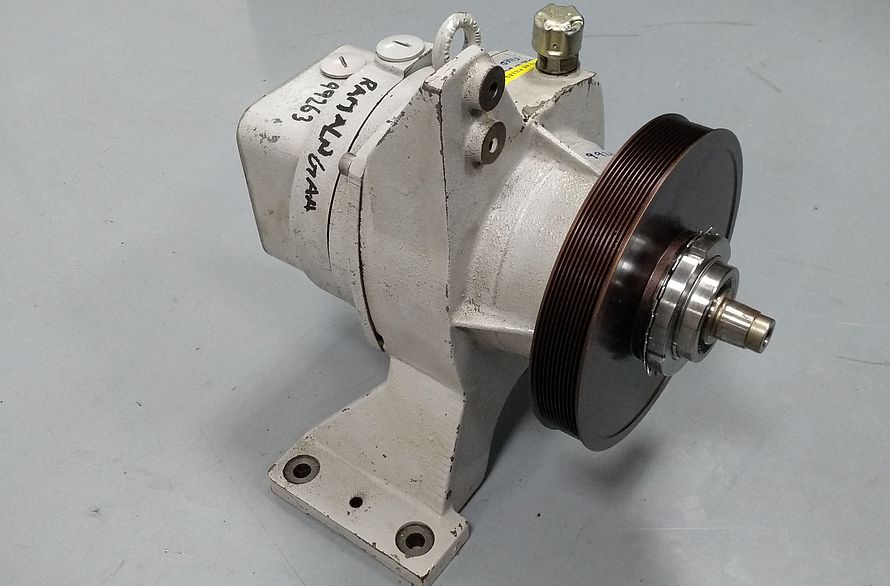

SERVOdrive Upgrade

This upgrade brings the regulated draw frame to a new level not only in terms of the dynamic levelling performance, but also regarding maintenance. It is the adaptation of the single drive concept of the latest machine generation (RSB-D 50) to the previous machines. The differential gearbox, motor and controller are removed and replaced by an electric drive control consisting of a SERVOdrive and a servo controller.

If any one of the following three parts are defective, it is time for an upgrade: levelling motor, differential gearbox or controller. If the other parts are still in good condition, they can be repaired by a technician of a local Rieter service center. A typical example for such a repair service is the gearbox as it will be disassembled and the internal parts will be fully replaced with parts that will extend the lifetime. Once returned, it can be used as emergency spare for the other conventional draw frames installed in the mill.

Top Roller Upgrade

For installed draw frames, the upgrade offers many advantages. While it looks pricy at first it is worth every penny. The tedious cleaning work at the bearing points is eliminated which leads to a much higher efficiency. The new top rollers have the same technical design and advantages as the ones used in the RSB-D 50. Thanks to the new factory-lubricated and sealed ball bearings, lapping and fiber build-up are a thing of the past. In addition, they perfectly fit into the existing mounts. The old axis, however, can no longer be used as the studs for the bearing support have changed.

Rieter’s Service Offering

Rieter supports customers in all matters during the entire life cycle of the machine with the extensive know-how of the Rieter After Sales organization. From maintenance, service, upgrade or retrofit, Rieter has the right offering.

Download

Manfred Rosenbach

Head Product Manager at PartsWinterthur

Switzerland