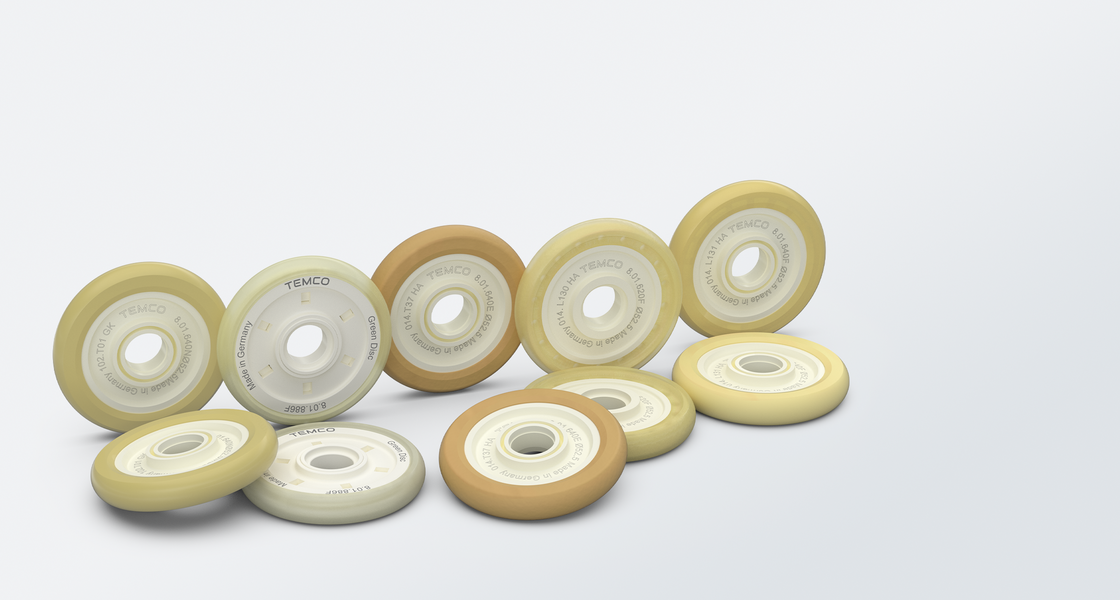

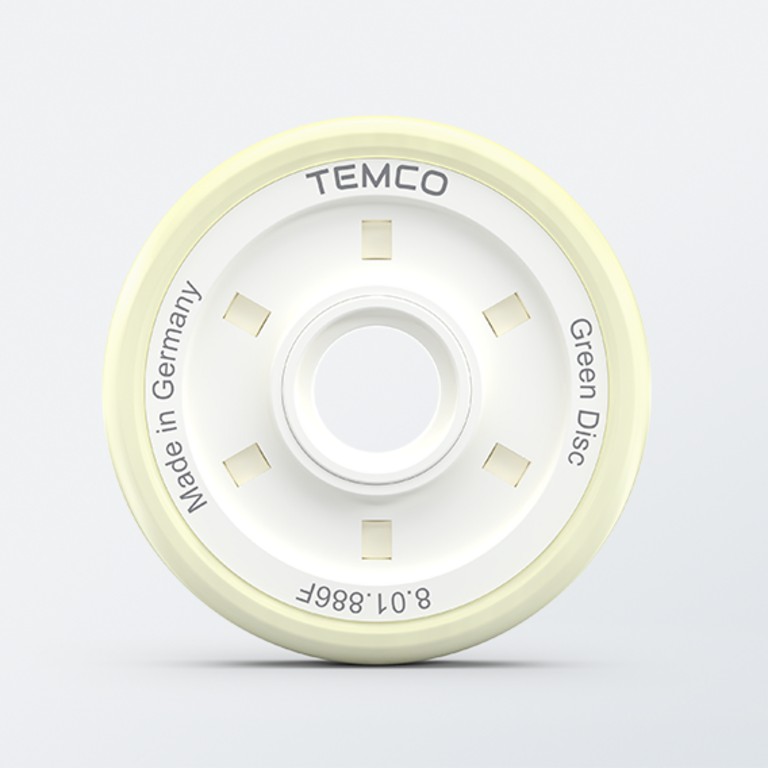

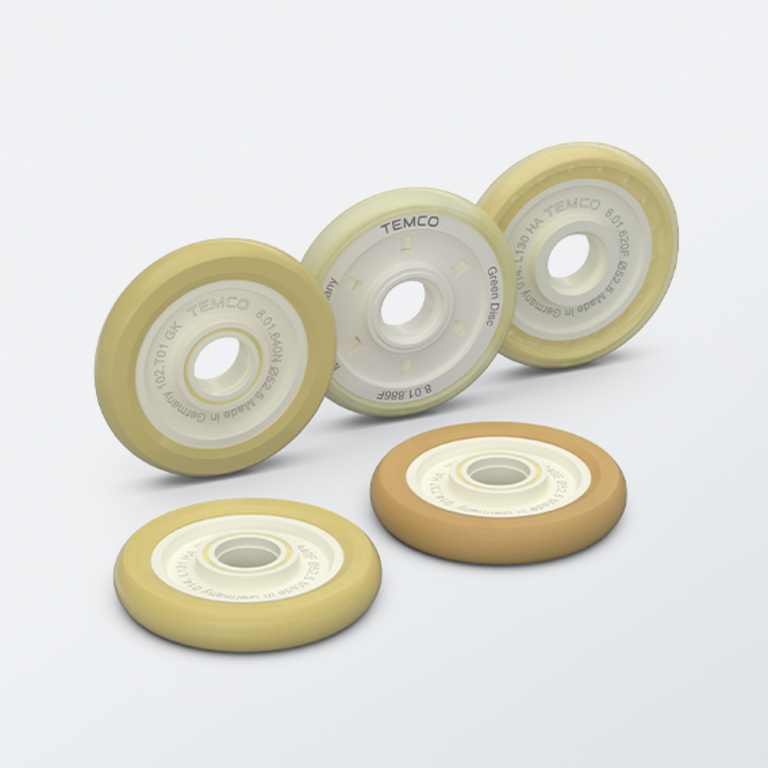

Product Details

Through developing polyurethane (PU) materials, optimizing the yarn geometry, adhering to tight manufacturing tolerances and ensuring strict quality control, Temco's PU texturing discs have set a new benchmark worldwide.

As pacemaker in the development of PU texturing discs Temco discs keep on setting new milestones in friction disc technology. The texturing experts are in close cooperation with universities and technology leaders in the textile industry. In-house research and development facilities include texturing machines with different profiles and heater types and a complete textile laboratory. The product portfolio offers the most suitable texturing discs with a range of thickness and diameters to satisfy all commonly used texturing units. Different shore hardness and shape can be selected to get the best results for the specific yarn range and processes.