ESSENTIAL at a glance

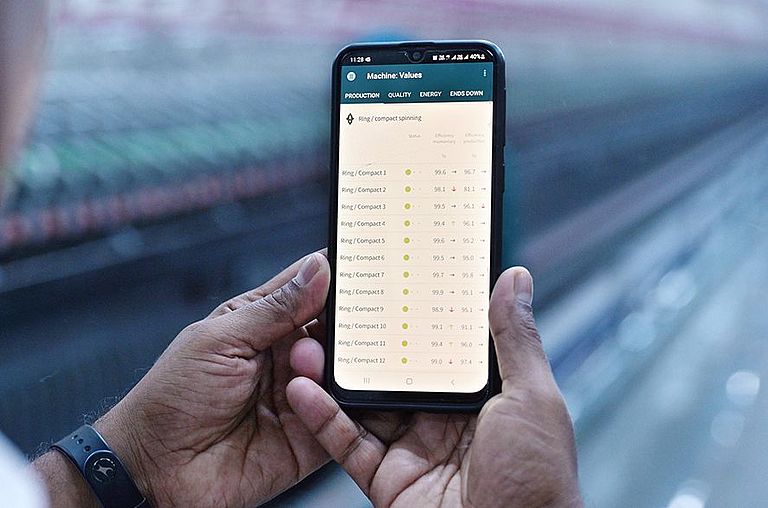

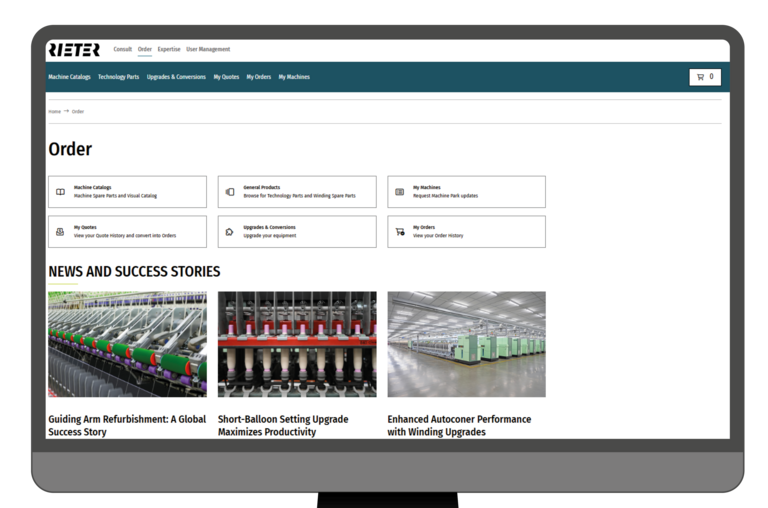

ESSENTIAL lets spinning mills significantly optimize their production and boost their fiber yield. This digital spinning mill management system records and connects all relevant data – from production and efficiency to energy consumption and quality – in real time.

As a result, management and operating personnel benefit from transparent information and a solid foundation for decision-making at all times. Spinning mill personnel can strengthen their specialist knowledge in specific areas, inefficiencies can be quickly identified and production processes can be optimized on a sustainable basis.

Through this holistic approach, ESSENTIAL connects every aspect of the spinning process, thus creating a firm basis for future-proof, fully automated yarn production.