Modernizing Compact-Spinning Machines the Smart Way

Converting timeworn Rieter compact-spinning machines to conventional ring spinning machines – optionally with compacting devices – is a viable solution when a machine has reached the end of its service life. This upgrade provides spinning mills with greater flexibility, boosts productivity by up to 10%, reduces imperfections and classimat values by up to 15%, and saves energy.

As a compact-spinning machine approaches the end of its operational life, typically after a decade or more of highquality performance, certain key technology components may require replacement. At this point, many customers begin evaluating options such as refurbishment, conversion, or new machine investment, a decision that involves both technical and financial considerations.

Smart and sustainable modernization

When investing in a new machine is not a preferred option, converting ageing compact-spinning machines into conventional ring spinning machines – optionally equipped with compacting devices – can be a practical and cost-effective solution.

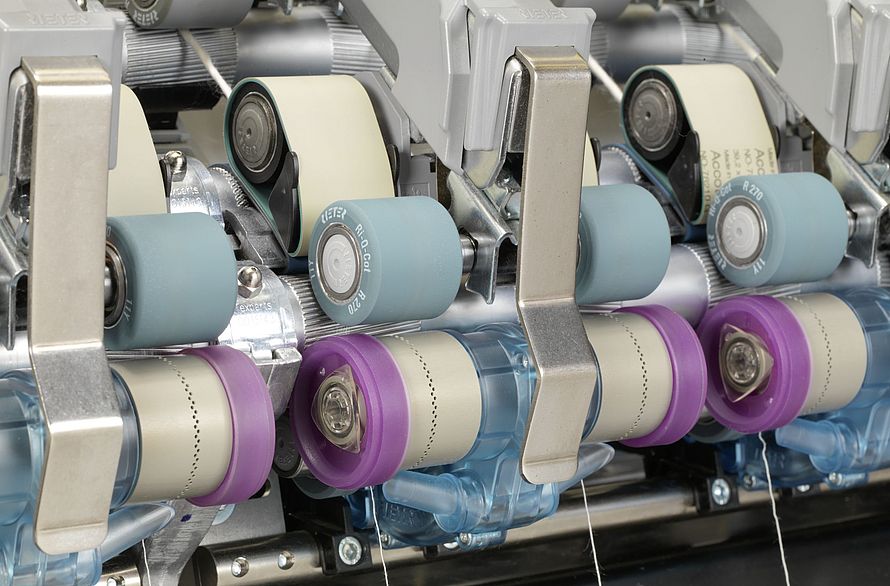

This conversion provides flexibility, allowing mills to produce ring yarn one day and compact yarn the next, enabling quick responses to changing market and customer demands. The process involves targeted modifications in the drives and drafting zones without altering the core structure of the machine.

Spinning mills can choose one of the latest generation compacting devices, like COMPACTapron, to meet specific quality and performance goals.

Increased productivity, enhanced quality, improved flexibility

The benefits of this smart upgrade are clearly visible in real-world applications. In a recent case, a Rieter compact-spinning machine K 43 was successfully converted to G 33 with COMPACTapron for processing Ne 60 cotton combed compact yarn.

The results compared to the timeworn compact-spinning machine were impressive: the yarn quality matched the original quality with the sieve drum system in terms of hairiness and strength (RKM) at an increased productivity of up to 10%. There is a substantial reduction in yarn imperfection and classimat values of up to 15%.

In addition, the latest compacting devices consume less energy due to reduced suction demand, leading to noticeable energy savings. The plug-in and plug-out design of the compacting devices allows for quick changeovers between compact and conventional ring spinning, supporting mills with increased flexibility to adapt swiftly to market demands. Offering a smart alternative to full replacement, this upgrade combines trusted machine performance with cutting-edge compacting technology.