Introducing E 86

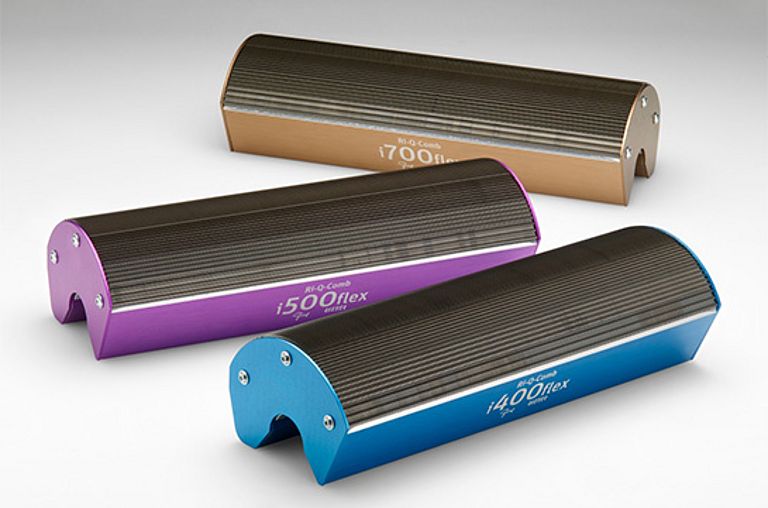

The comber E 86, with its high production and its unequaled quality, leads the way in combing. Individual quality requirements can be fulfilled thanks to the new height-adjustable integral circular comb, Ri-Q-Comb.

The established, fully automated ROBOlap lap changing and piecing system is the standard for modern combing operations. Together with the unique OMEGAlap preparation, the highest production per set on the market is achieved.