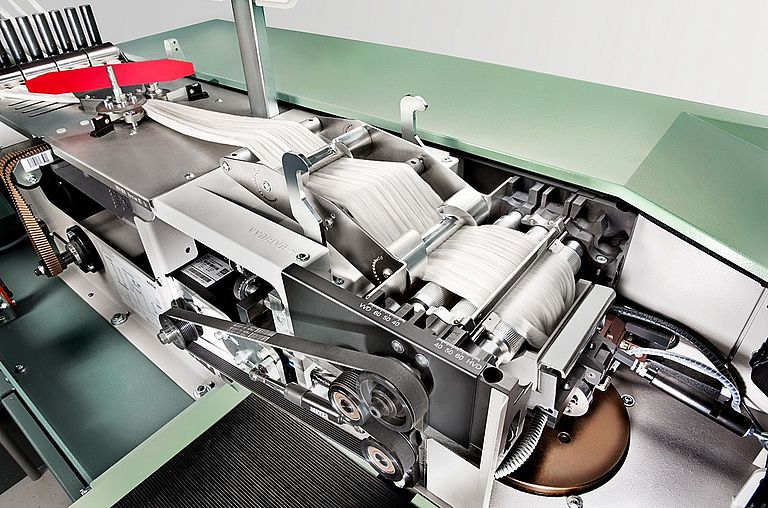

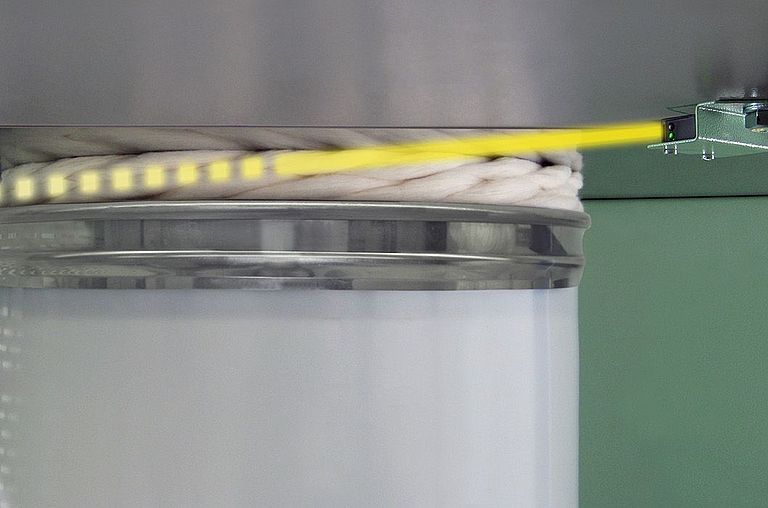

Boosting Performance

After several years of operation, machines do not meet today's requirements anymore and require a little boost to recover their initial productivity. Rieter provides a wide range of solutions to bring your equipment up to its best levels and even beyond.